About CH Leading

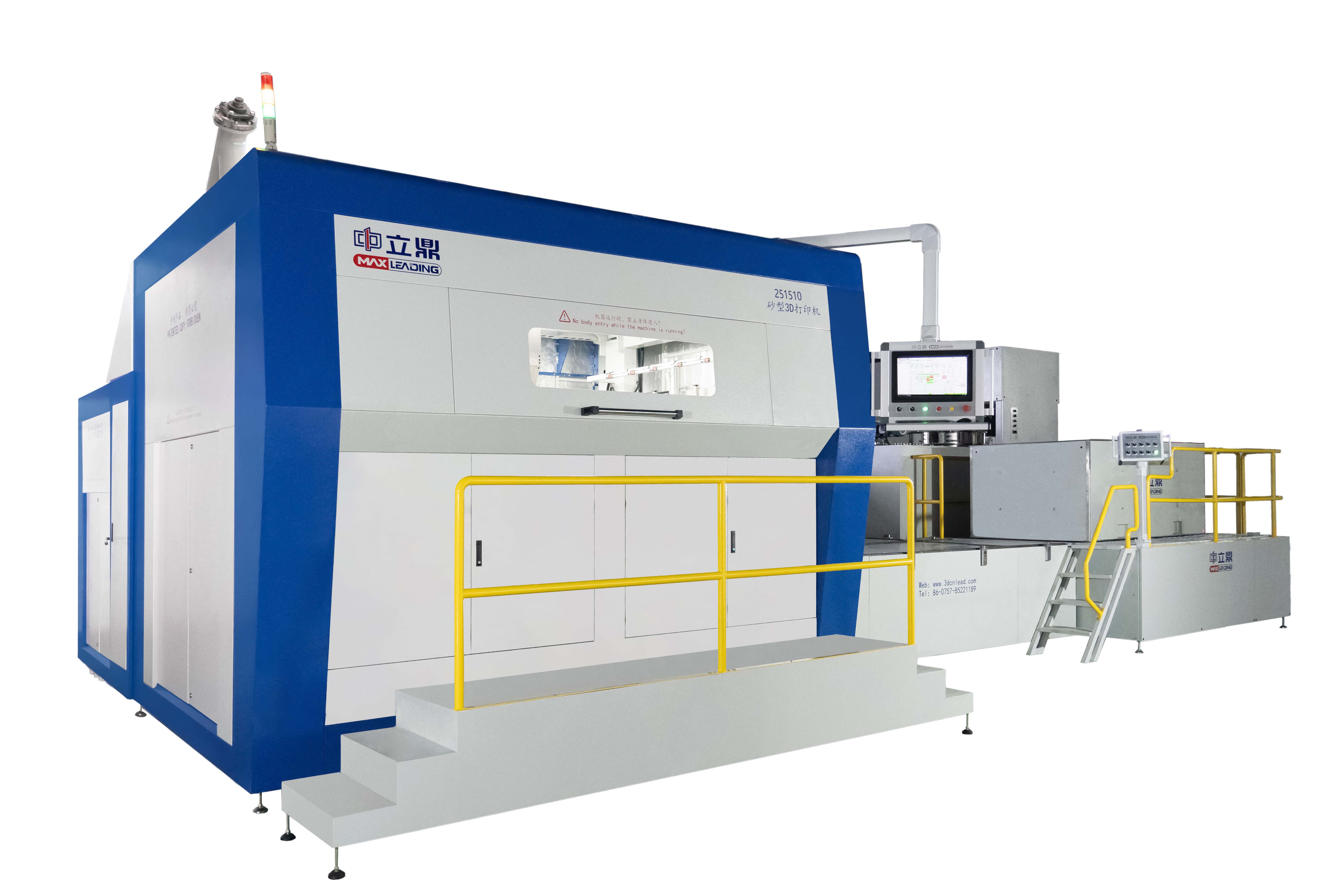

CH Leading Additive Manufacturing (Guangdong) Co., Ltd. (CH Leading) is a high-tech enterprise specializing in the research and development, manufacturing, and application of industrial 3D printing equipment for sand and ceramic molds. With a team of professional sand 3D printing experts, we are dedicated to designing efficient, durable, and cost-effective 3D printers.

Our technology helps foundries and model shops transform traditional sand casting processes, enabling digital production, eliminating rigid molds, and making the production of previously impossible geometries a reality.