About Acenter Tools

Acenter Tools is a leading manufacturer of cutting tools based in Changzhou, China. Specializing in carbide end mills, carbide drills, HSSE taps, and custom tooling solutions, we deliver precision-engineered products trusted by CNC machining professionals worldwide.

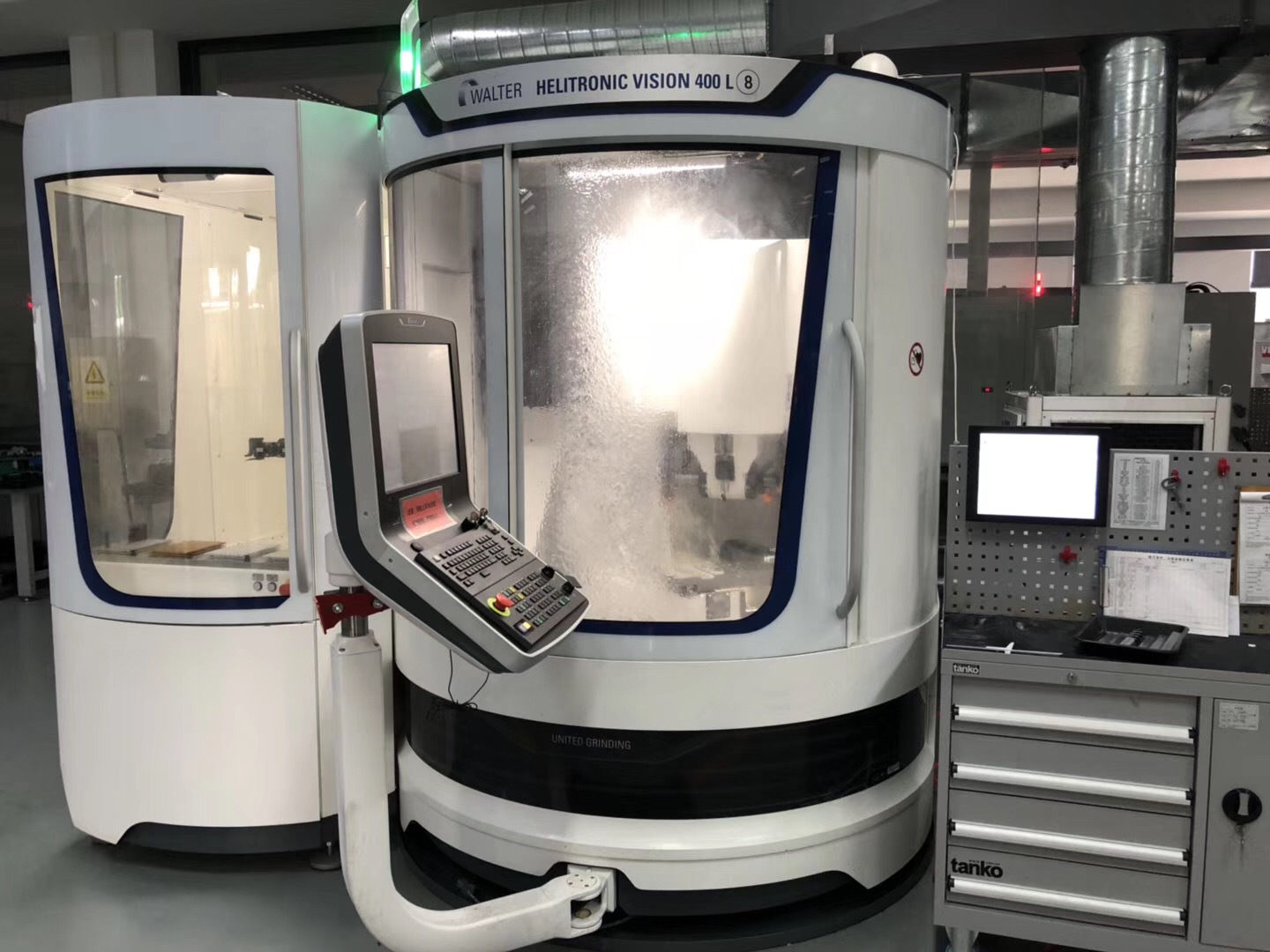

With advanced manufacturing capabilities and strict quality control, our tools are designed for reliability, durability, and consistent performance in demanding industrial applications. From standard inventory items to fully customized tooling, we support your production needs with engineering expertise and fast turnaround.

- ISO-Certified Manufacturing Facility

- Custom Tool Design & Engineering Support

- Global Shipping with Fast Lead Times