Welcome to China Alloy Parts

Widest Acknowledged Range of Low Expansion Alloys in Europe | Expert Knowledge & Advice with Over 70 Years Combined Experience

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Widest Acknowledged Range of Low Expansion Alloys in Europe | Expert Knowledge & Advice with Over 70 Years Combined Experience

China Alloy Parts Ltd. is a globally recognised stockist of low and controlled expansion alloys, including Invar 36, Kovar, and Alloy 42. With a UK-based inventory of unrivalled size, we deliver high-quality, fully certified alloys to industries worldwide.

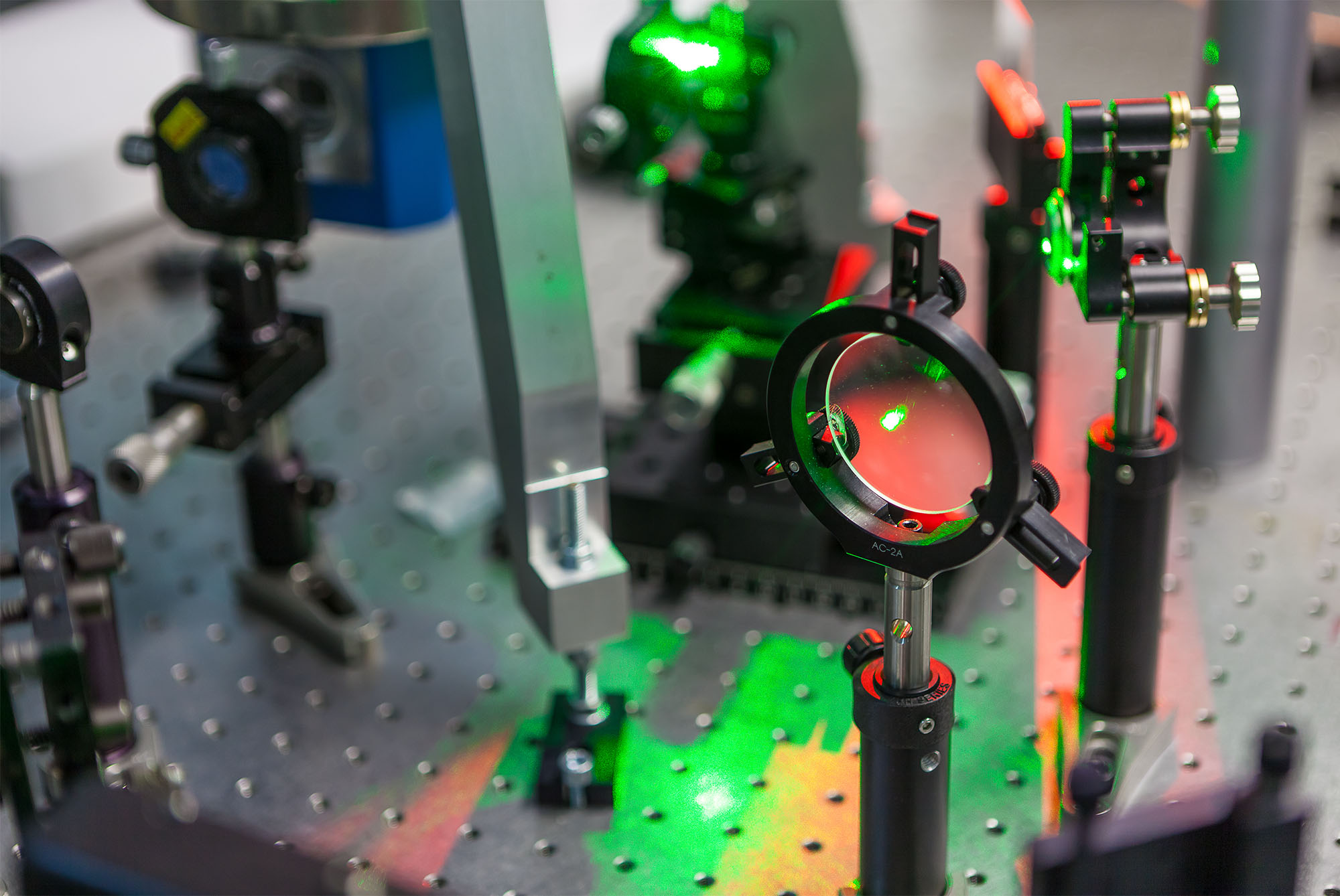

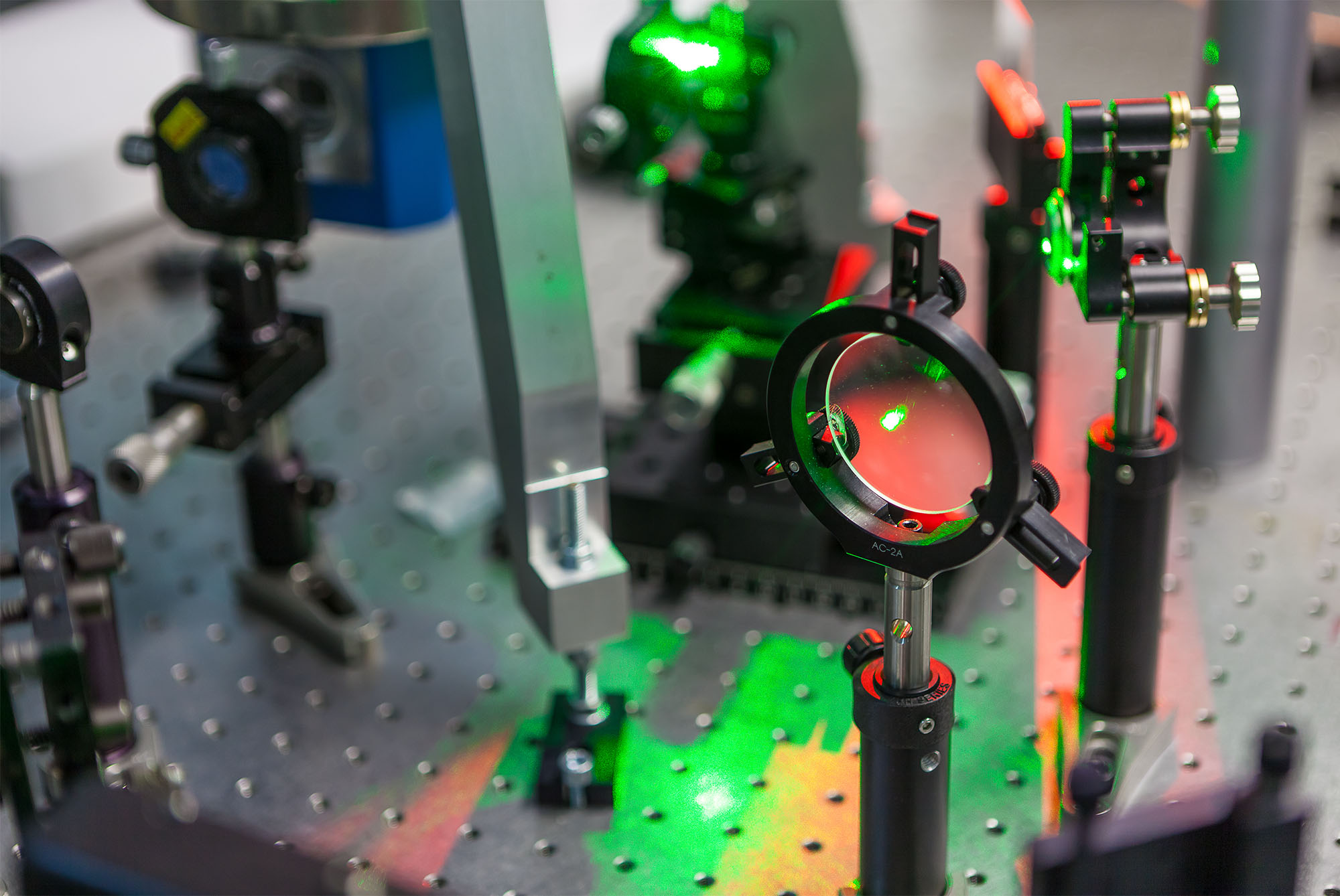

Accredited with the AS9120/ISO9001 Quality Management System since 2015, our team combines over 70 years of industry expertise to provide bespoke solutions for aerospace, defence, oil & gas, optical laser, and more.

70+

Years Combined Experience

2001

Established

AS9120

ISO9001 Certified

We stock and supply a comprehensive range of low expansion and specialty alloys. All materials are professionally cut, profiled, and machined to specification — always on time.

A nickel-iron-cobalt alloy designed for glass-to-metal sealing. Exhibits near-zero thermal expansion over a wide temperature range.

FeNi36 alloy with near-zero thermal expansion. Ideal for precision instruments and cryogenic applications.

Low thermal expansion alloy suitable for glass and ceramic sealing in electronic packaging.

Enhanced version of Invar with cobalt addition for even lower thermal expansion.

Oxygen-Free High Conductivity copper, ideal for vacuum and high-purity environments.

Lightweight, high-strength alloys available in grades 1–12. Excellent corrosion resistance.

Nickel-based superalloy with excellent strength and corrosion resistance at high temperatures.

High melting point (2623°C), excellent thermal conductivity, and low thermal expansion.

The China Alloy Parts warehouse stocks a much wider range of alloys. Contact us if you don't see the alloy you're looking for.

Our specialty alloys are trusted across high-performance sectors requiring precision, durability, and reliability.

Precision components for satellites, engines, and avionics using Invar, Kovar, and Inconel.

High-reliability alloys for radar, missile systems, and secure communication devices.

Corrosion-resistant Inconel and titanium for downhole tools and offshore platforms.

Low-expansion alloys for laser cavities, mirrors, and precision optical mounts.

China Alloy Parts is proud to hold AS9120 and ISO9001 certification since 2015, reflecting our commitment to quality management and customer satisfaction.

Speak to our experts today for quotes, technical advice, or custom alloy solutions.

Phone: +86-755-29861980

Email: inquiry.alloy@shapedparts.com

Address: Building A, No.17 Guangjin Road, Shapu, Songgang, Bao'an, Shenzhen, China. 518105

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info