Engineered Strength Since 2008

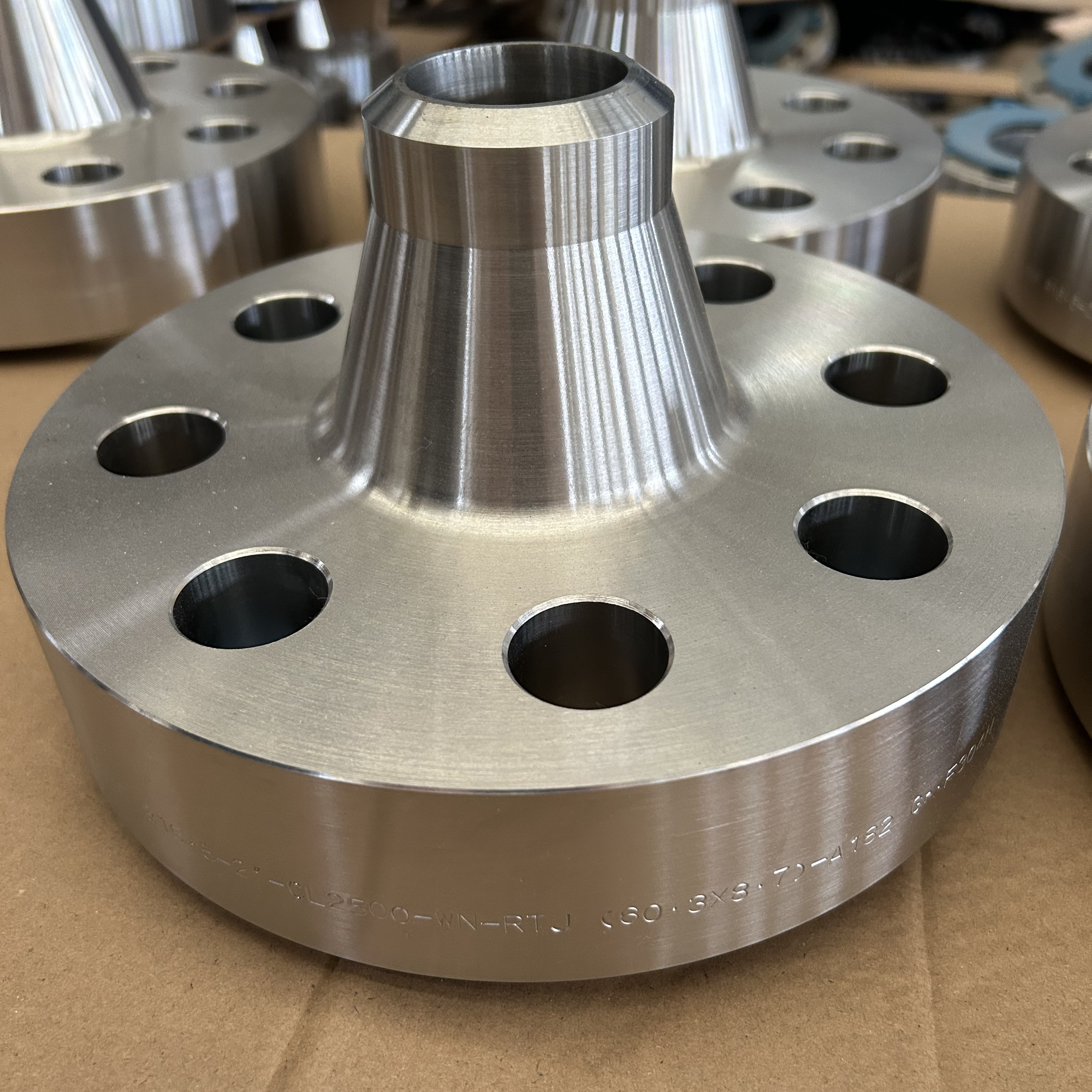

Liangjiang Forging is a leading manufacturer of high-performance forged components, specializing in custom solutions for critical industrial environments. With over 15 years of expertise, we deliver precision-forged rings, discs, sleeves, shafts, blanks, and flanges that meet stringent global standards.

Our products are trusted in wind turbines, gearboxes, power plants, offshore platforms, and heavy machinery where reliability under extreme conditions is non-negotiable.

- ISO 9001:2015 Certified

- ASME, ASTM, DIN, JIS, GOST Compliant

- Full Material Traceability & Testing

- OEM & Custom Design Support