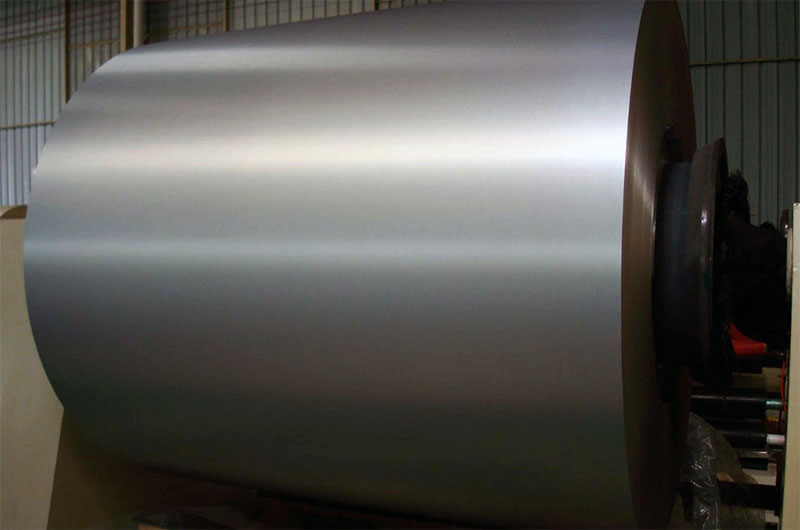

Trusted Partner in Aluminum Coil Manufacturing

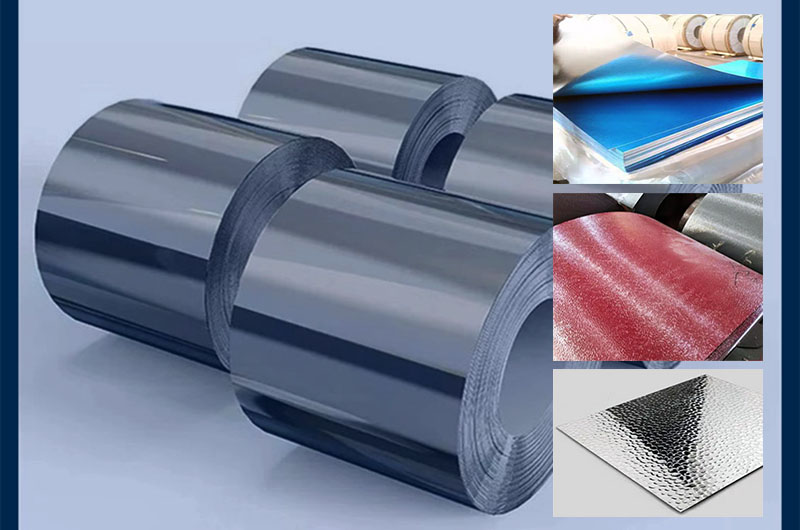

Haomei Aluminum has years of experience in producing high-quality aluminum coils, serving industries worldwide. Our products are exported to over 160 countries and trusted by leading global brands.

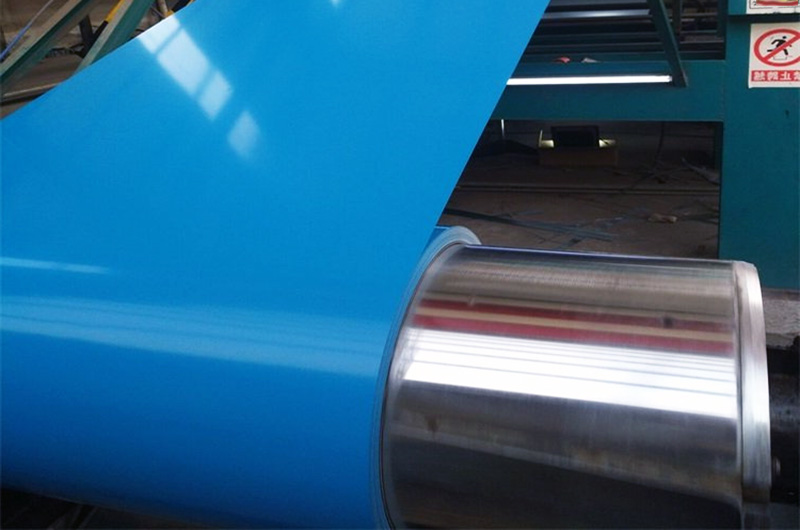

We regard quality as life and users as God. Every process, every product, and every user is treated with the highest responsibility. Our production systems are certified under ISO 9001, AS9100, DNV, BV, and CCS standards.