About Hengzhong Heavy

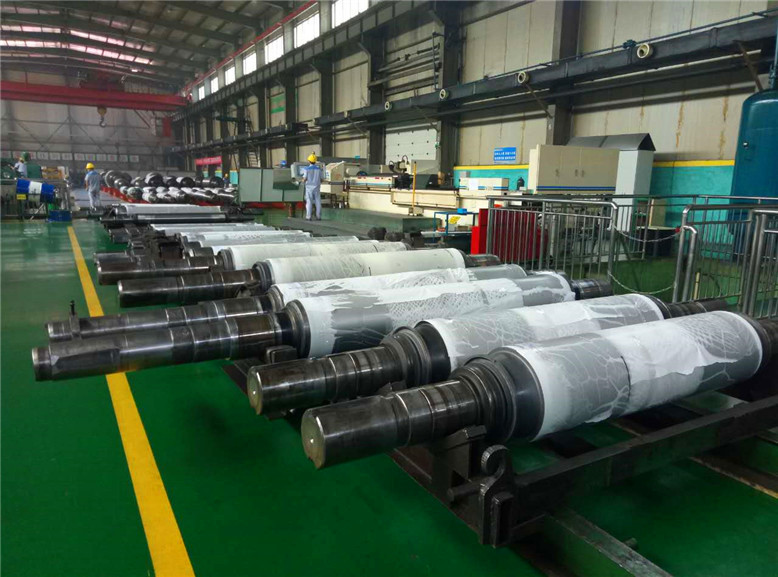

Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. is a leading manufacturer specializing in aluminum casting and rolling equipment. With years of engineering expertise, we deliver high-performance solutions for aluminum processing industries worldwide.

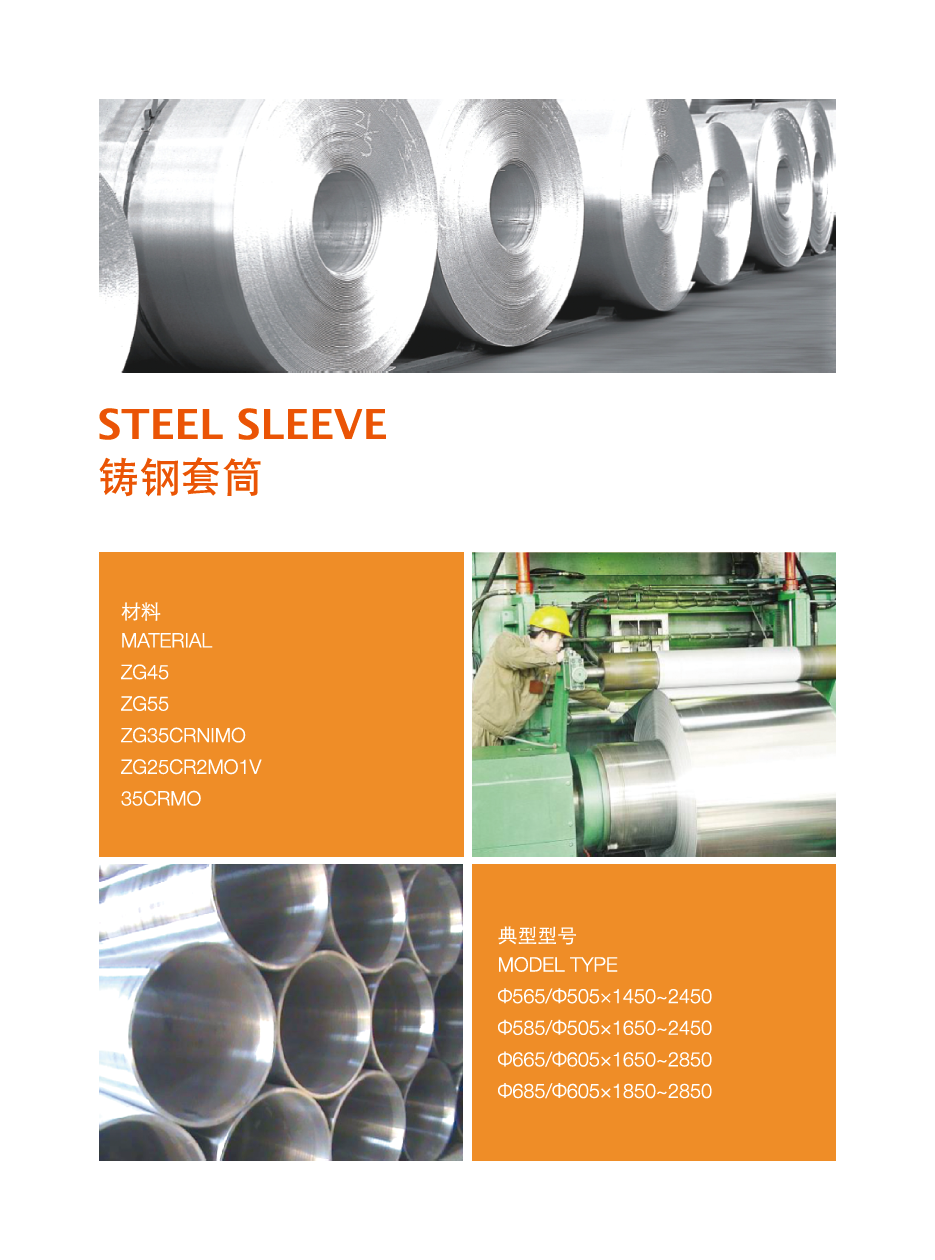

Our product range includes aluminum casting rolling mills, cold rolling machines, foil rolling equipment, tension leveling lines, cut-to-length lines, slitting machines, and precision cast rolls. We also supply high-quality aluminum sheets, coils, plates, circles, and color reflectors.