About Audop

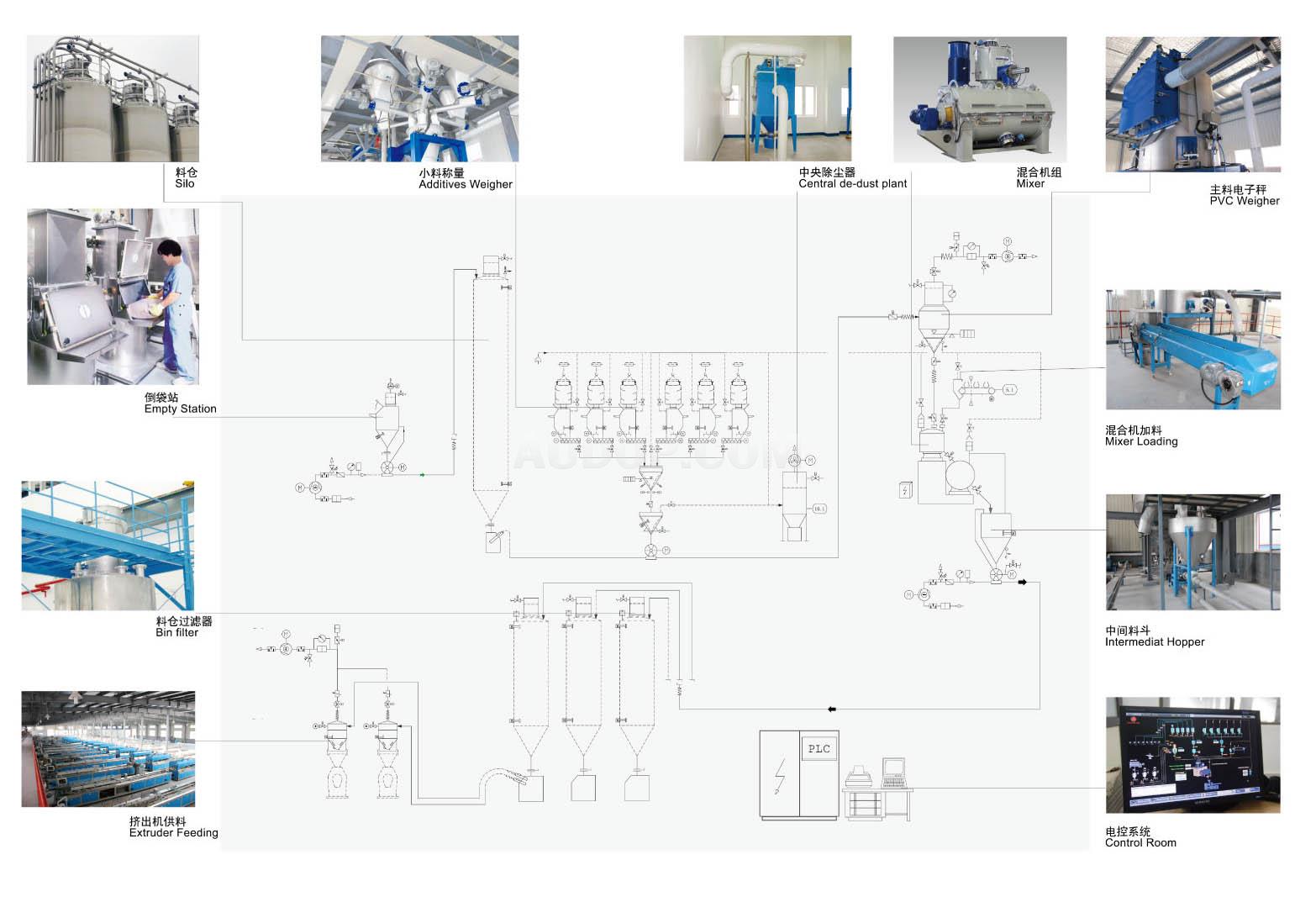

Audop Company Limited is a joint venture established in Hong Kong by leading Chinese manufacturing companies specializing in plastic compounding, extrusion, and recycling technologies. From day one, Audop has been backed by a powerful technical team with over 25 years of industry experience.

Our mission is simple: deliver high-performance, durable, and innovative machinery that helps our global clients succeed in the evolving plastics industry. With a strong focus on quality, affordability, and customer satisfaction, we’ve become a trusted supplier across continents.

High Quality

From raw materials to final output

Competitive Pricing

Long-term partnership focus