8 Advantages of the Vision Inspection System

Discover how automated visual inspection improves quality, reduces costs, and increases throughput.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

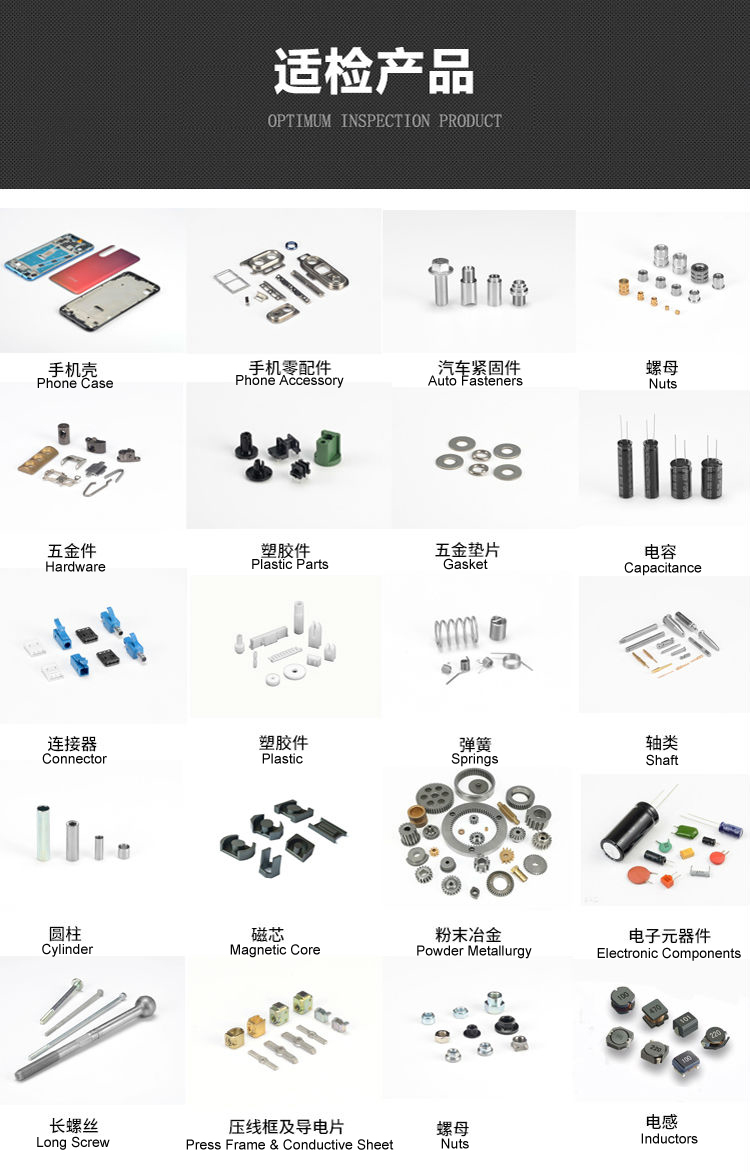

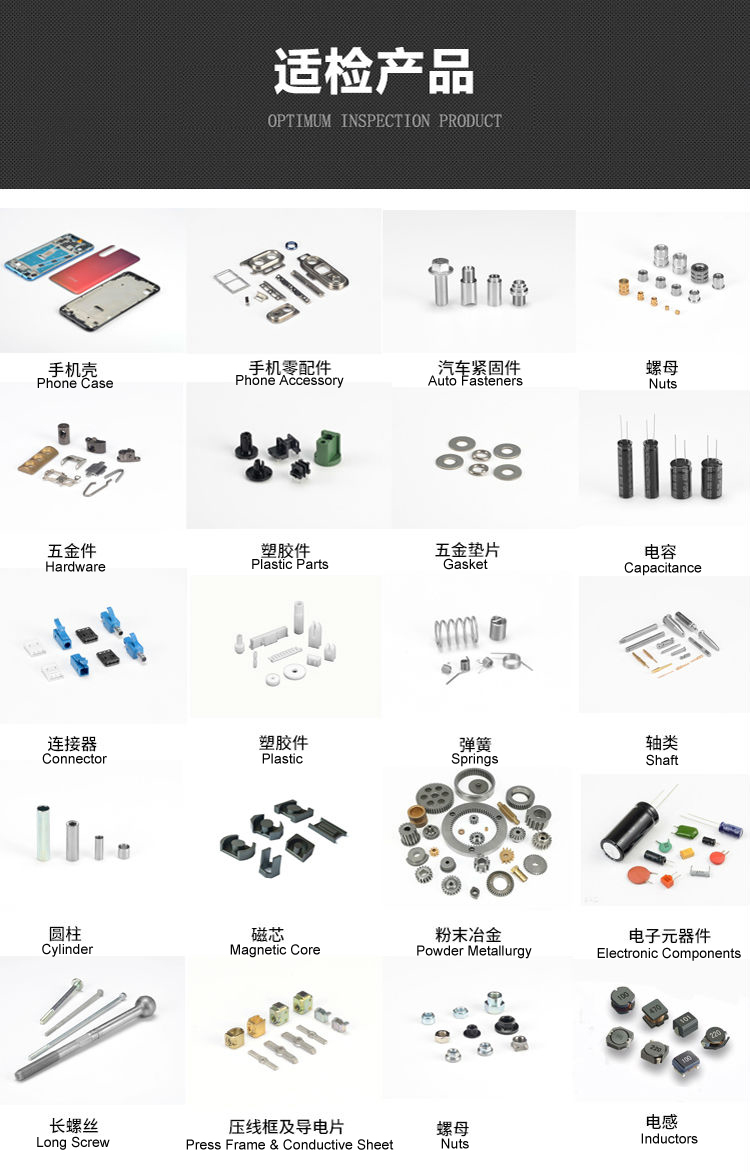

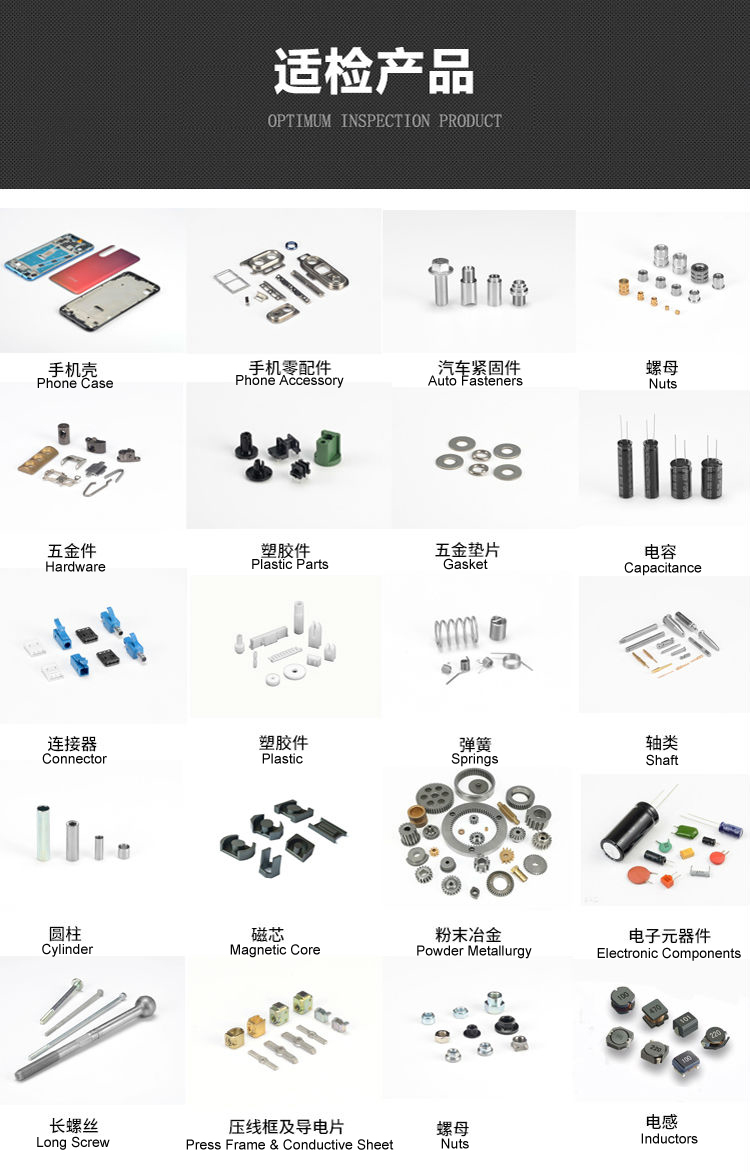

Precision automated visual inspection solutions from China — trusted by global manufacturers in hardware, electronics, plastics, and new energy industries.

Explore Our MachinesWe AUTOMATICROBOT specialize in all kinds of Visual Inspection Machine, Optical Sorting Machine, Vision Inspection System, and Machine Vision Camera. With years of engineering expertise, we deliver automated inspection solutions tailored to your production needs.

Our systems serve diverse industries including hardware, electronics, plastic parts, magnetic materials, and new energy battery manufacturing. From fastener inspection to O-ring defect detection, our vision technology ensures 100% quality control with unmatched speed and accuracy.

High-precision, automated optical inspection systems designed for industrial quality assurance across multiple sectors.

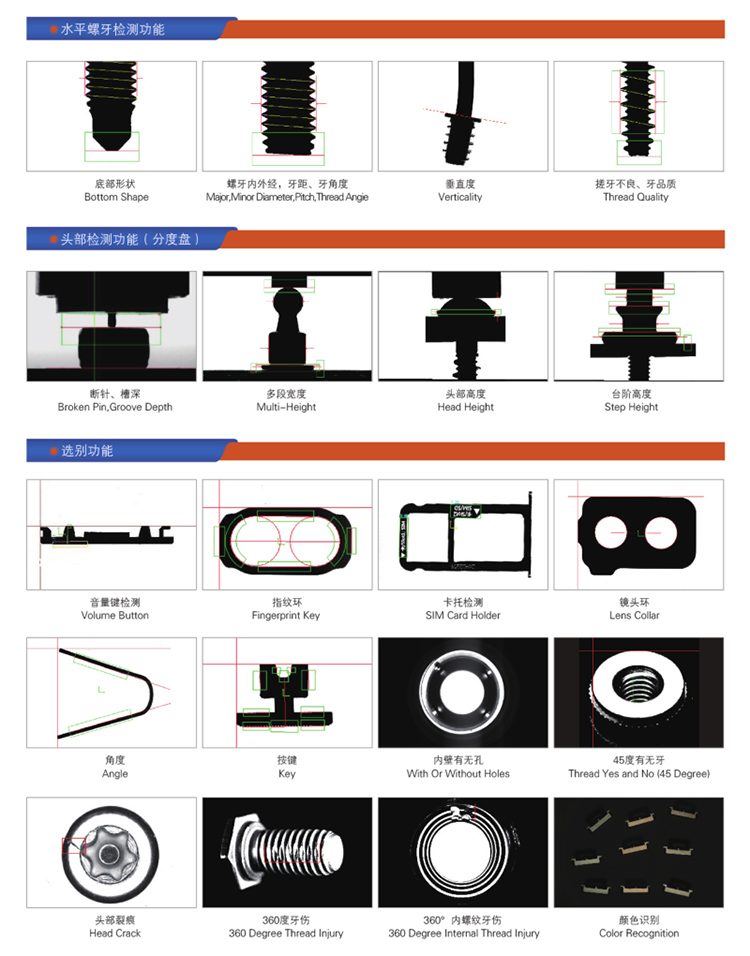

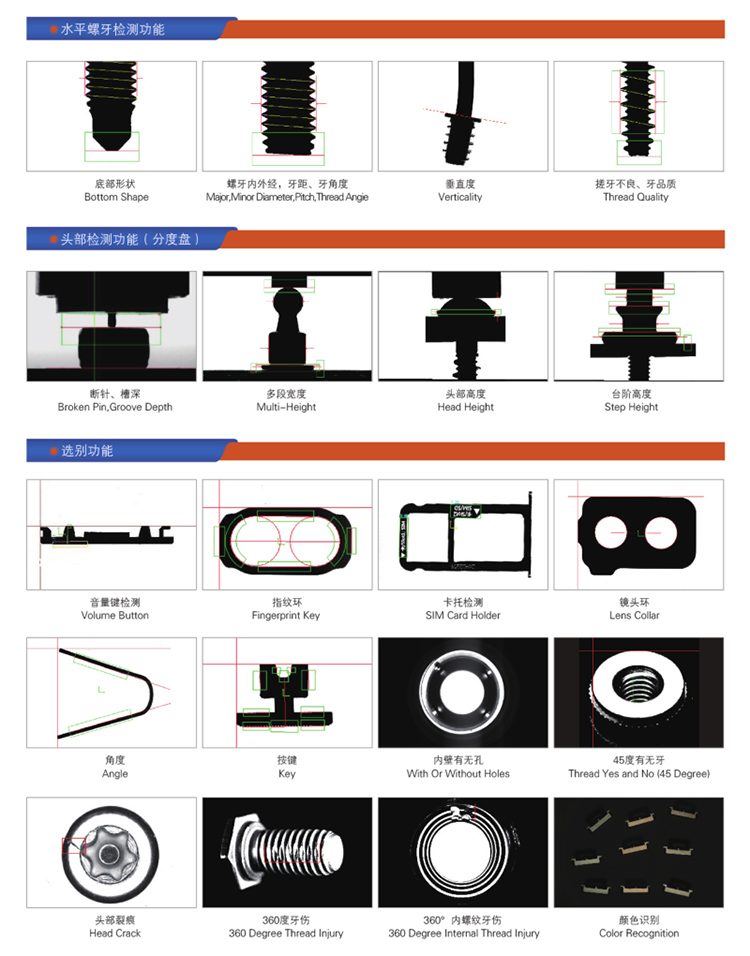

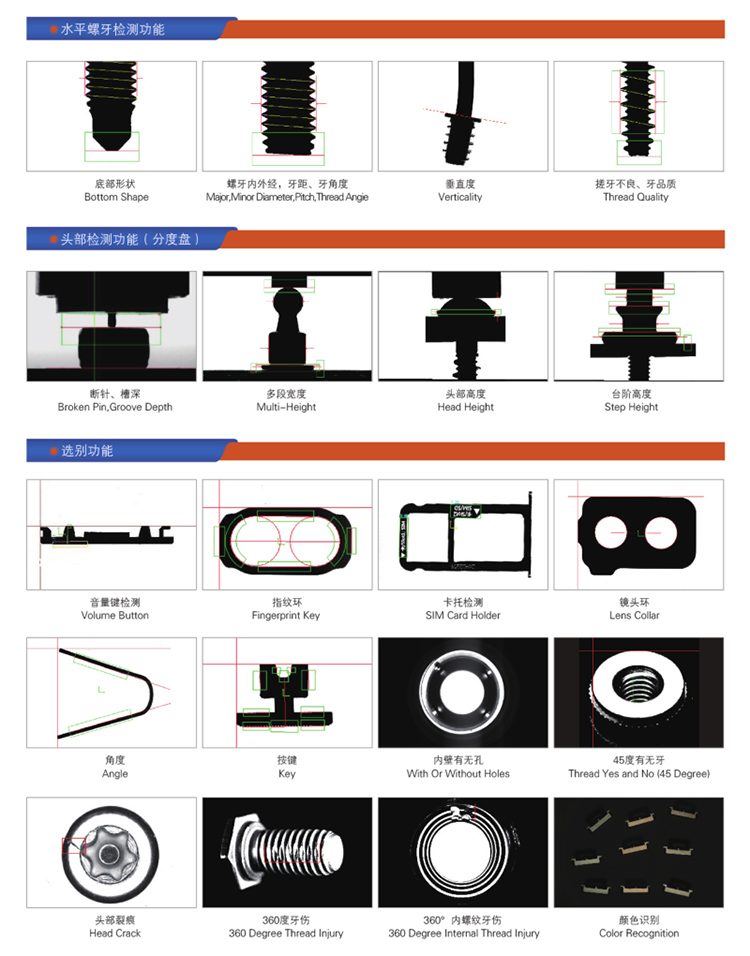

Automated defect detection for screws, pins, and metal fasteners using high-resolution CCD imaging and AI-based analysis.

Detects surface defects, color variations, and dimensional inaccuracies in injection-molded plastic components.

Specialized system for detecting cracks, deformities, and surface flaws in silicone and rubber sealing rings.

High-speed inspection of electronic capacitors and SMD components with precision dimensional and visual checks.

Dedicated imaging module for real-time monitoring of threaded fasteners, bolts, and screws on production lines.

Inspects ferrite and magnetic cores for chipping, cracks, and dimensional consistency in transformer manufacturing.

Comprehensive inspection of lithium-ion battery cells for electrode alignment, casing defects, and contamination.

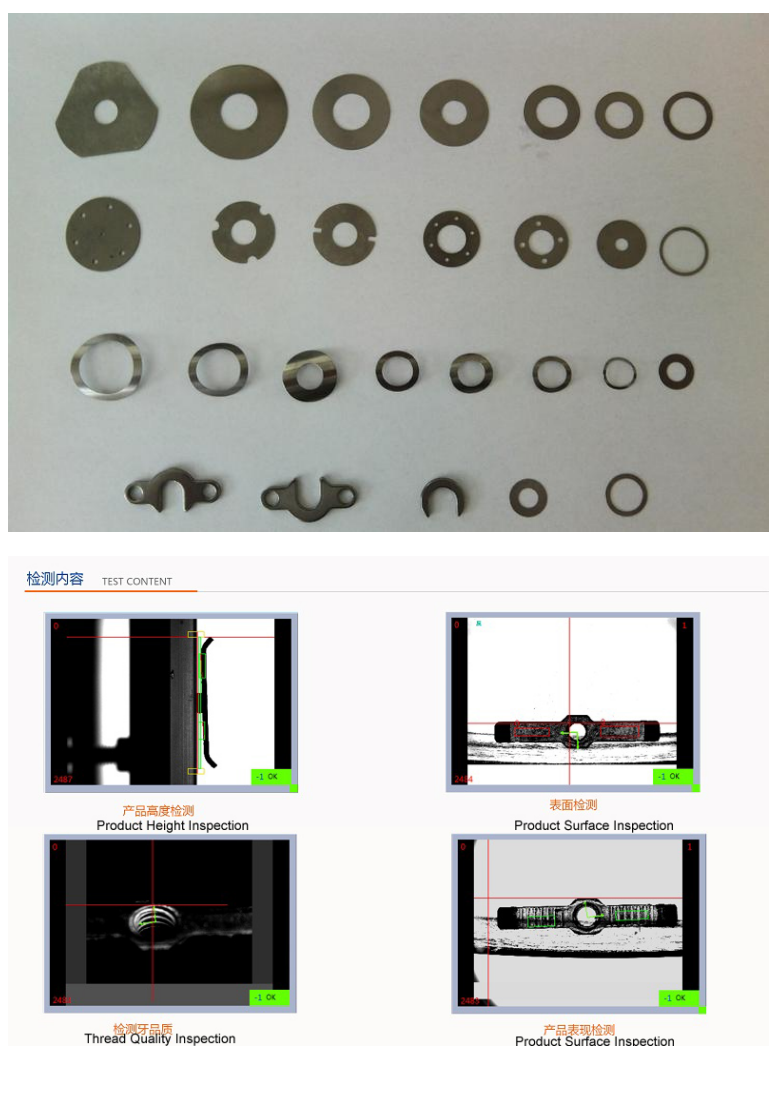

Ensures sealing integrity by detecting cuts, tears, compression set, and material inconsistencies in gaskets.

Engineered for reliability, precision, and seamless integration into your production line.

Eliminate human error with consistent, round-the-clock inspection capabilities.

Inspect thousands of parts per hour without slowing down your production line.

Adaptive algorithms improve over time, reducing false positives and increasing accuracy.

Designed to work with existing conveyors, PLCs, and factory automation systems.

Real-world applications of our vision inspection systems across industries.

Automated detection of bent, broken, or misaligned pins in connector manufacturing.

Verifies thread integrity, length, and tip geometry with micron-level precision.

Used in medical device manufacturing for flaw detection on stainless steel needles.

Stay updated with trends in machine vision and industrial automation.

Discover how automated visual inspection improves quality, reduces costs, and increases throughput.

Case study on inspecting washers, rings, and circular fasteners with 360° imaging.

Why more manufacturers are replacing human inspectors with automated systems.

Ready to automate your quality inspection process? Contact us today for a free consultation.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info