Who We Are

Yancheng ACE Valve Co., Ltd.

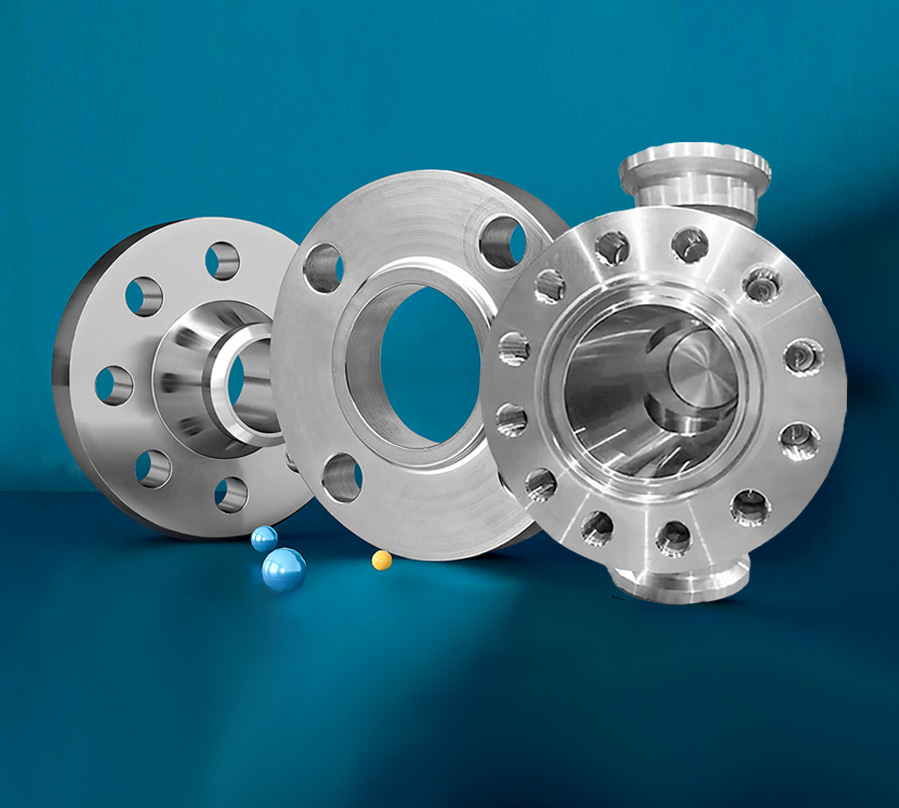

Located in Yancheng, Jiangsu Province, ACE Valve is a professional manufacturer of forgings and special alloy material valve components and accessories. We serve critical industries including oil & gas, chemical processing, power generation, mining, water treatment, and general industrial systems.

Our team of 60 dedicated professionals brings decades of experience in production, factory management, quality control, and international marketing. This expertise ensures we meet the highest standards in every product we deliver.

- ISO-Certified Manufacturing Processes

- Global Supply to 30+ Countries

- On-Time Delivery Rate Over 98%

- Full Material Traceability & NDT Testing