About BETON Mechanical Seal Factory

Founded in 1983, NINGBO BETON MECHANICAL SEAL FACTORY is a high-tech enterprise specializing in the design and manufacturing of all types of mechanical seals and filtration components. With over four decades of experience, we deliver reliable sealing solutions for demanding industrial applications.

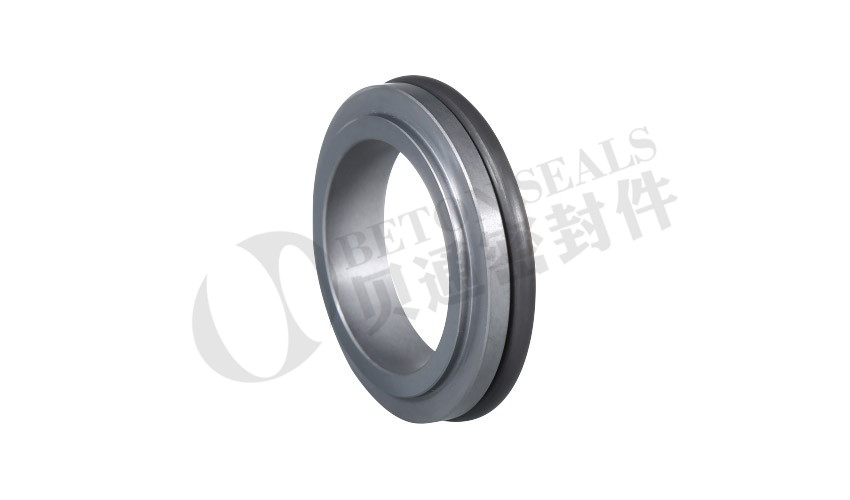

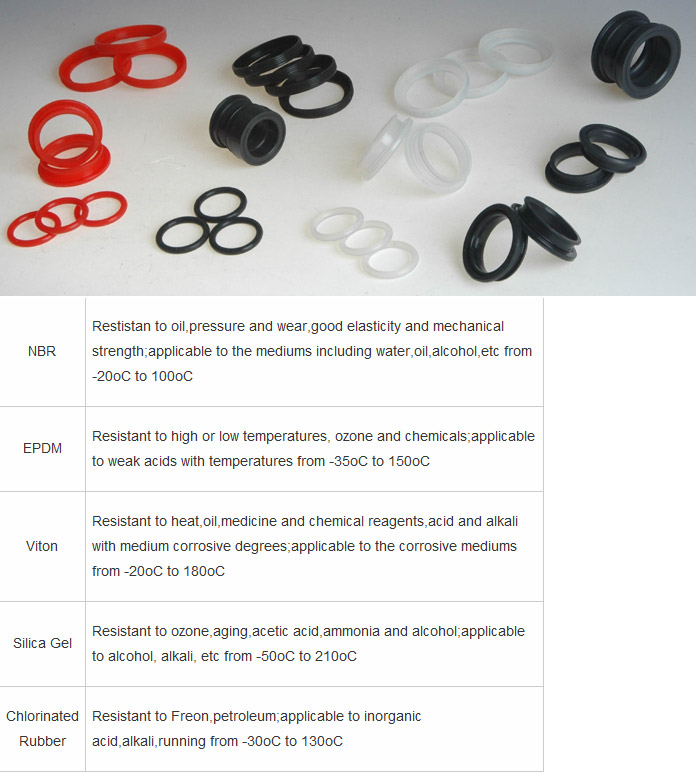

In 2001, we achieved ISO9001 international quality certification, affirming our commitment to excellence in every product we manufacture. Our comprehensive range includes O-ring seals, rubber bellow seals, PTFE wedge seals, metal bellow seals, cartridge seals, and custom OEM solutions.