About Cambridge Vacuum Engineering

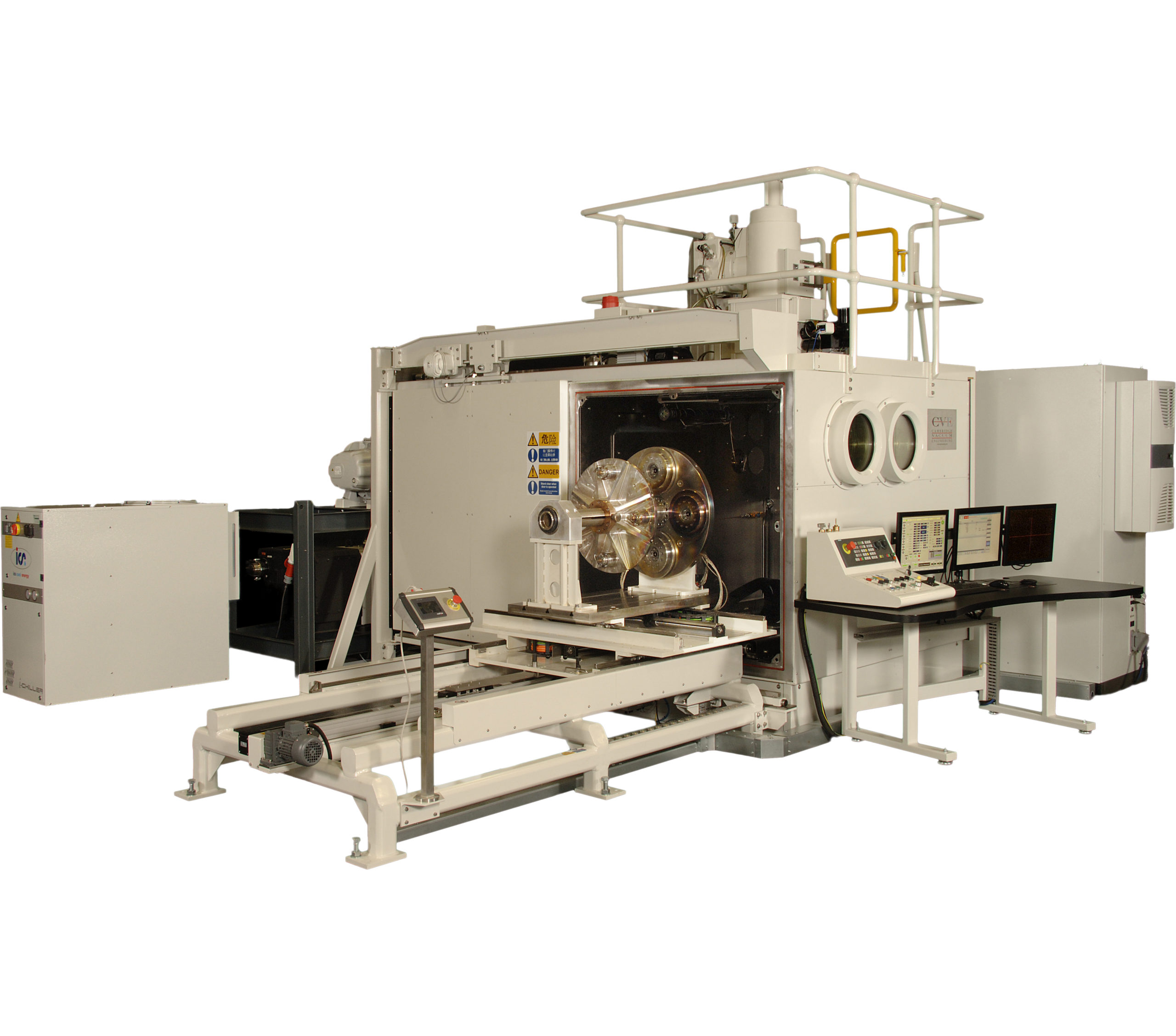

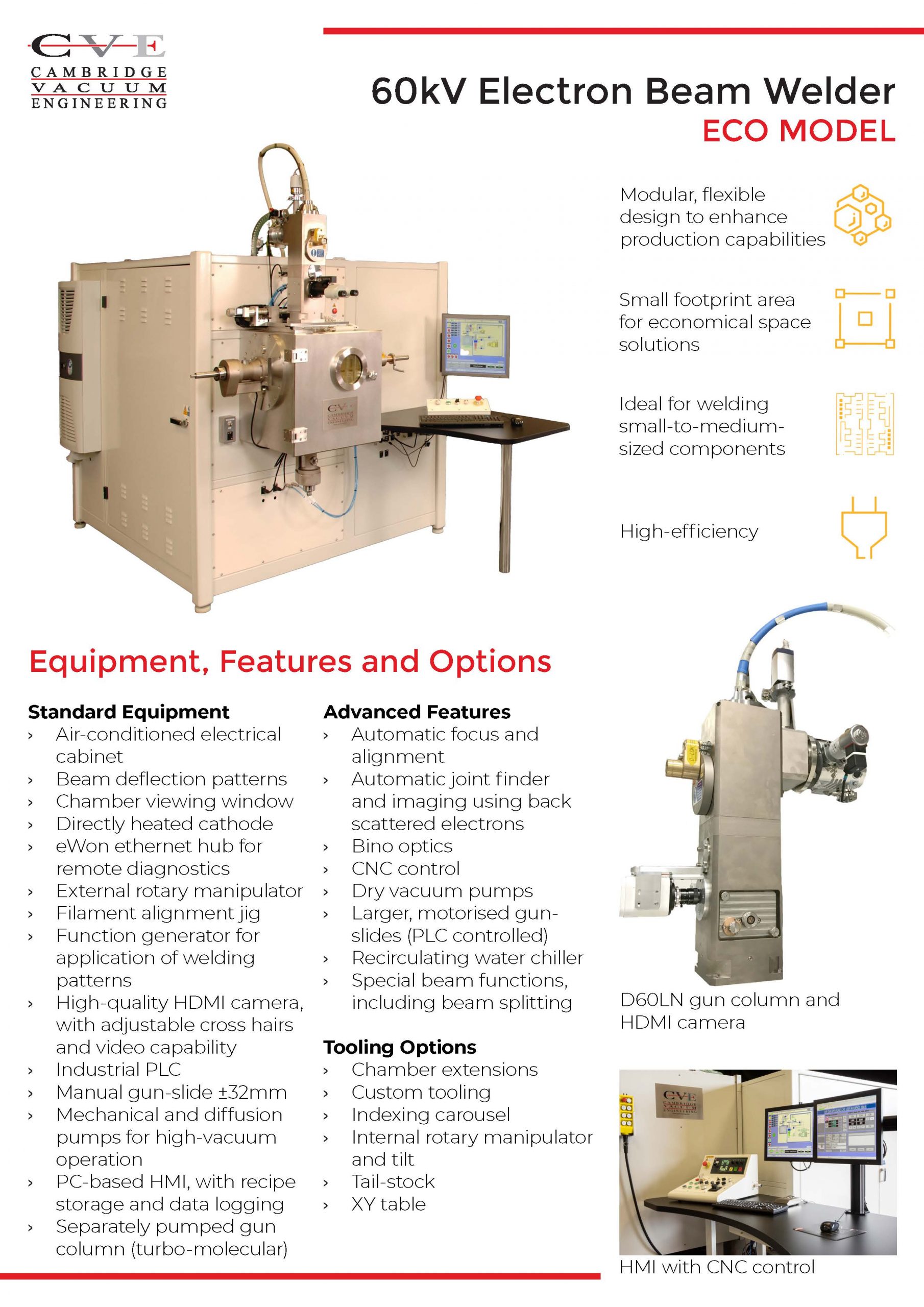

Cambridge Vacuum Engineering (CVE) is a world leader in the design, manufacture, and service of electron beam and laser welding systems. With decades of innovation and engineering excellence, we deliver high-precision solutions trusted by industries across the globe.

Our commitment to quality and performance has earned us the "Great Place To Work" certification, reflecting our culture of collaboration, innovation, and employee satisfaction.

- Pioneers in local vacuum electron beam technology

- Specialized systems for EV components, aerospace, and turbochargers

- Global customer support and service network