About SINOWARES

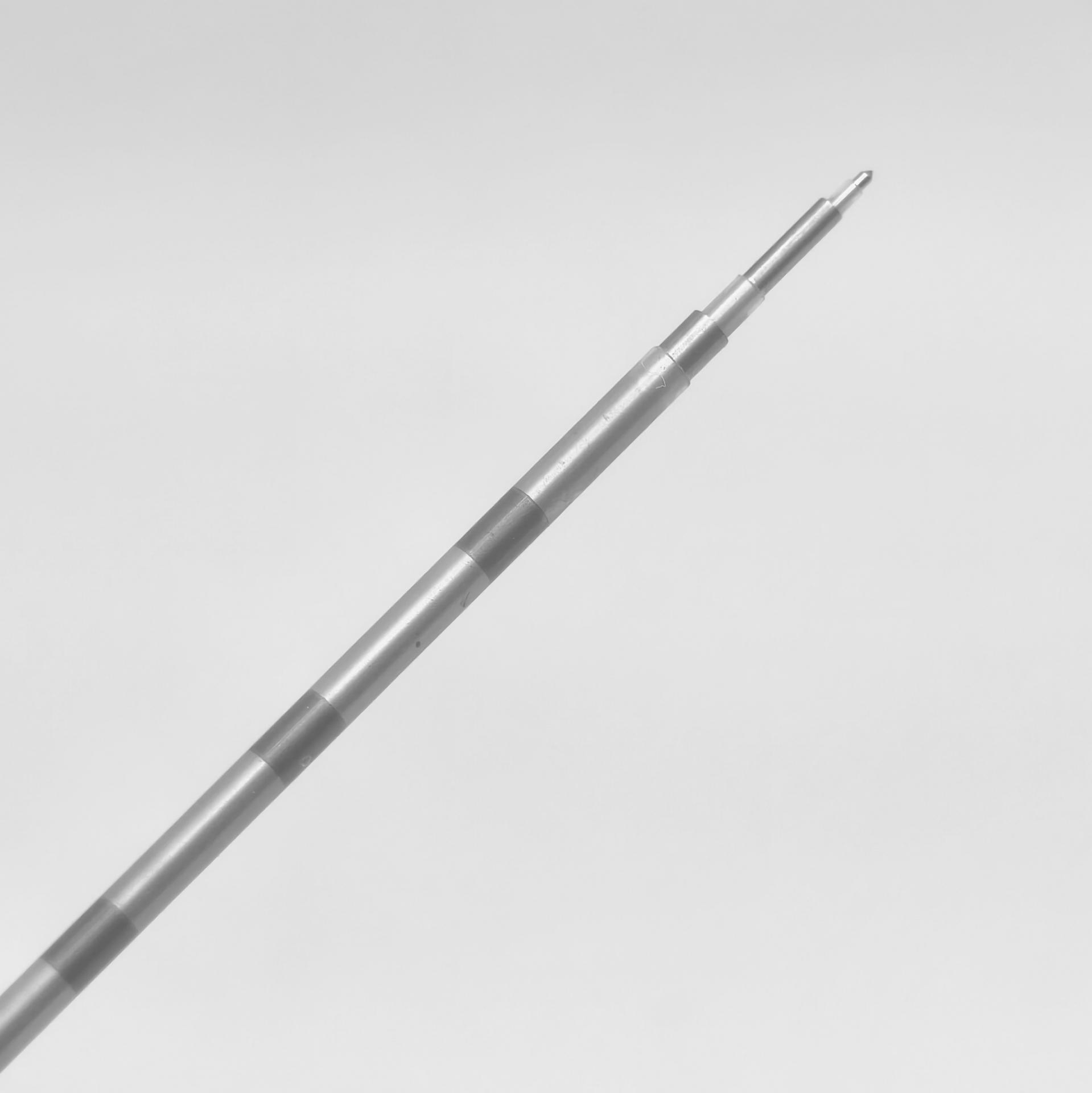

Founded in 2002, Shenzhen Sinowares Technology Co., Ltd. has been a pioneer in the development and manufacturing of precision micro tubing and minimally invasive surgical instrument structures. With over two decades of experience, we specialize in solving complex engineering challenges in medical device design.

As a National High-Tech Enterprise (2019) and Shenzhen High-Tech Enterprise (2018), our R&D team has achieved multiple technological breakthroughs in micro-imaging, puncture systems, ultrasonic scalpels, and ablation electrodes. We are committed to innovation, quality, and strategic partnerships in the global healthcare industry.

OEM & Custom Solutions

Tailored designs for unique medical applications

Patented Technologies

Multiple patents in micro-structure realization