About YizeMold

China Yize Mold Co., Ltd. was founded on January 1, 2007, and is located in Chang'an Town, Dongguan — known as the "China Mold Town". With 132 dedicated employees, we specialize in the precision machining of tungsten carbide products.

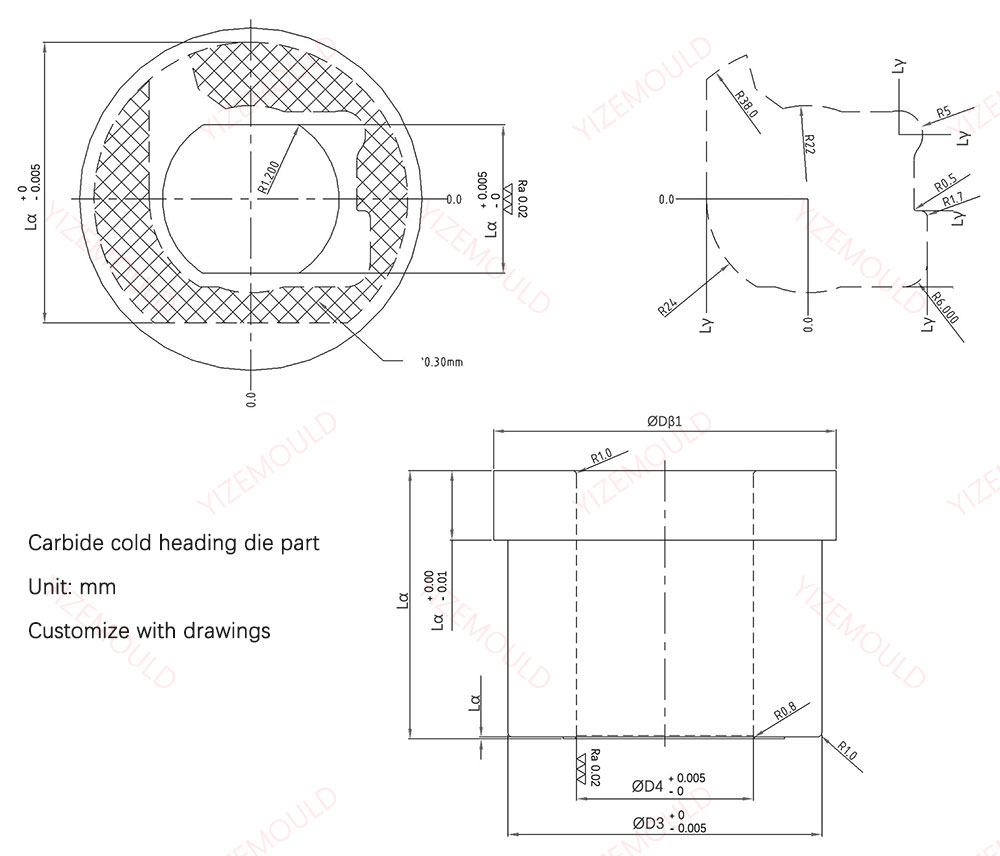

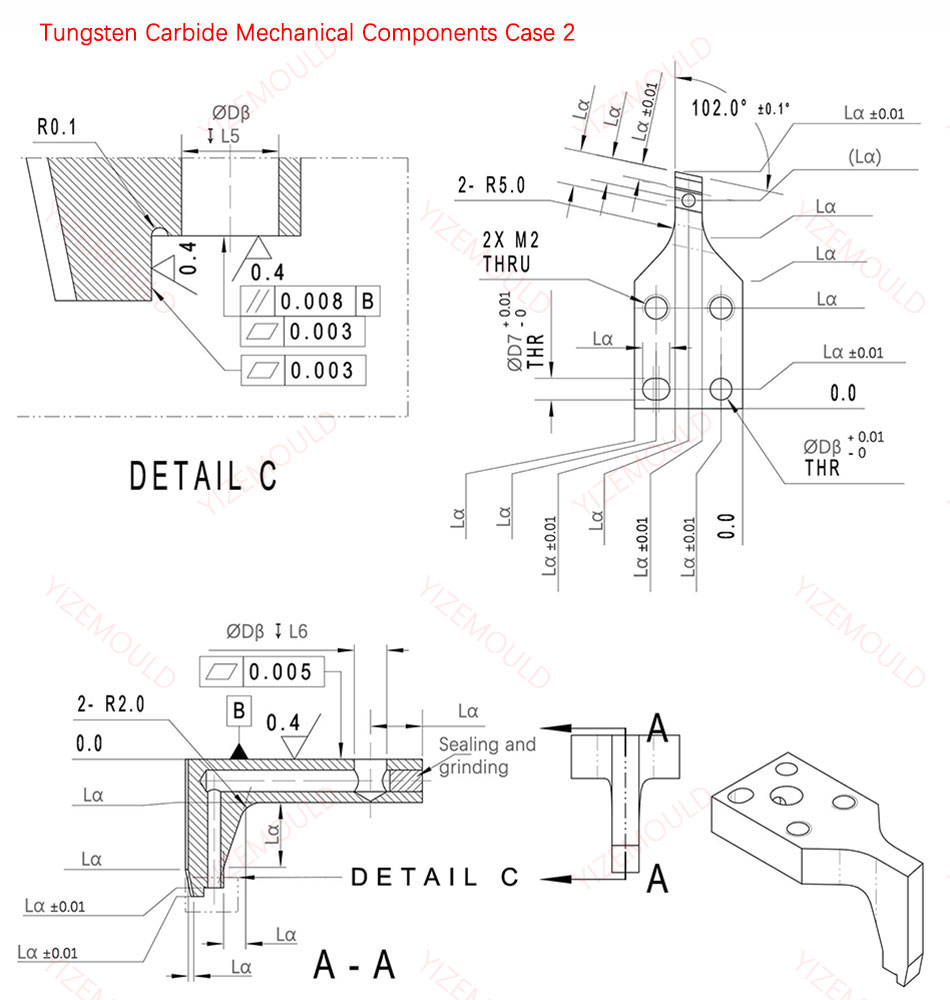

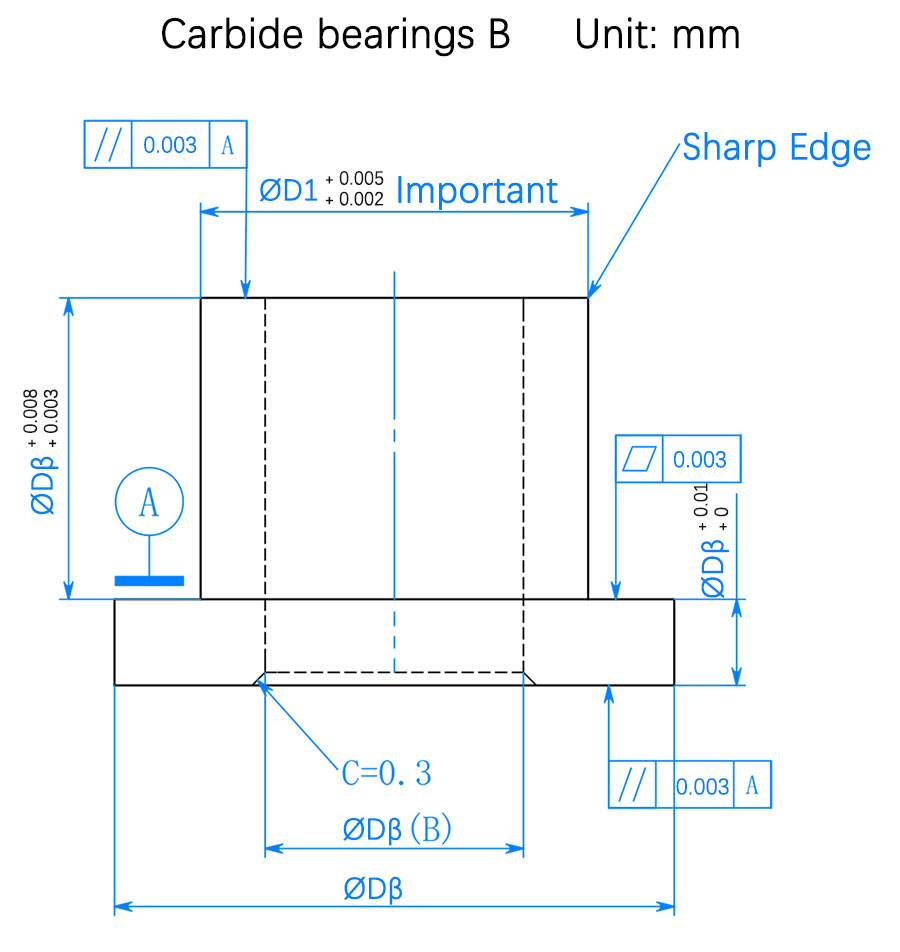

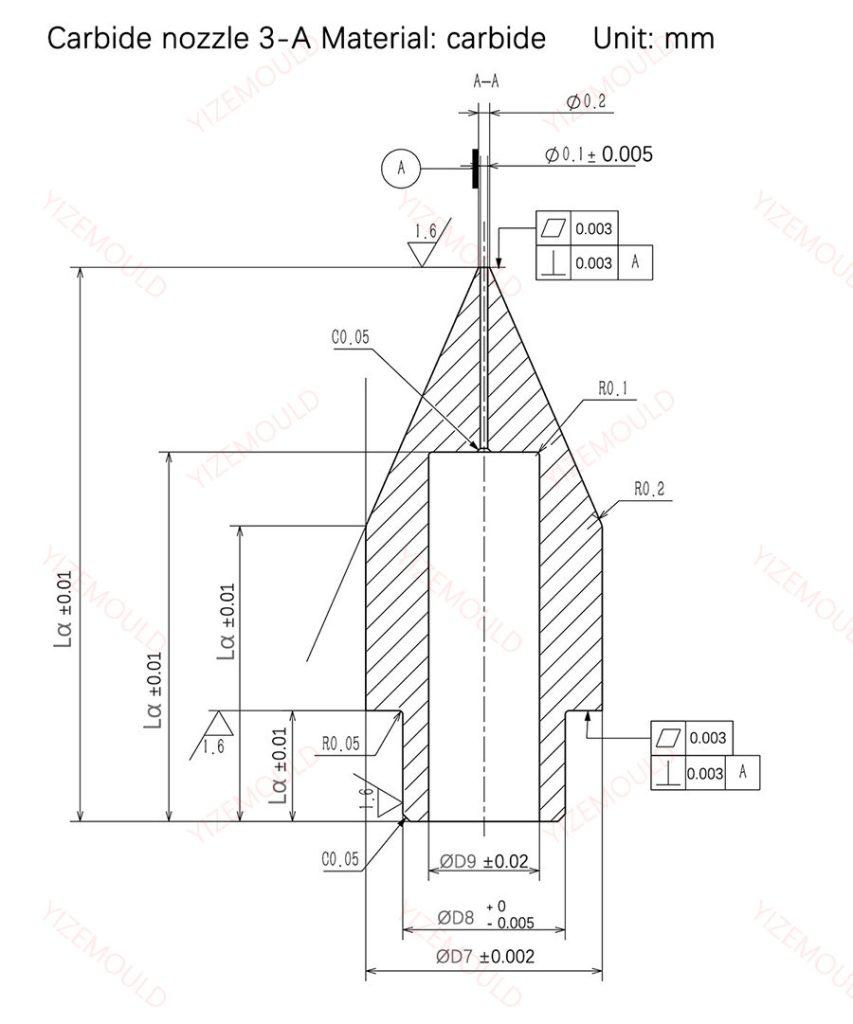

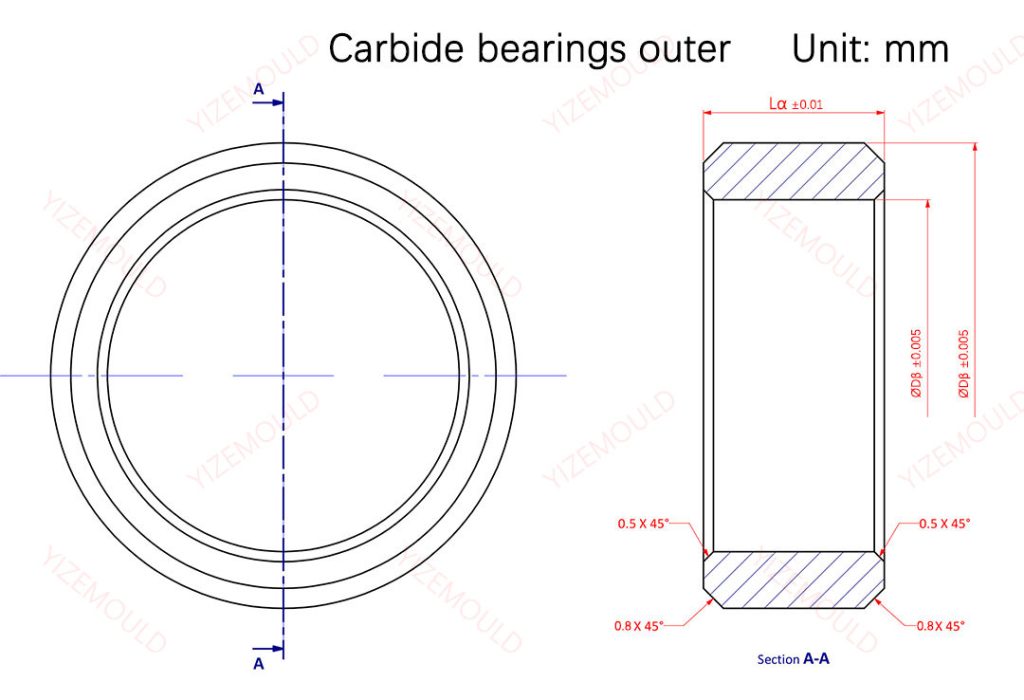

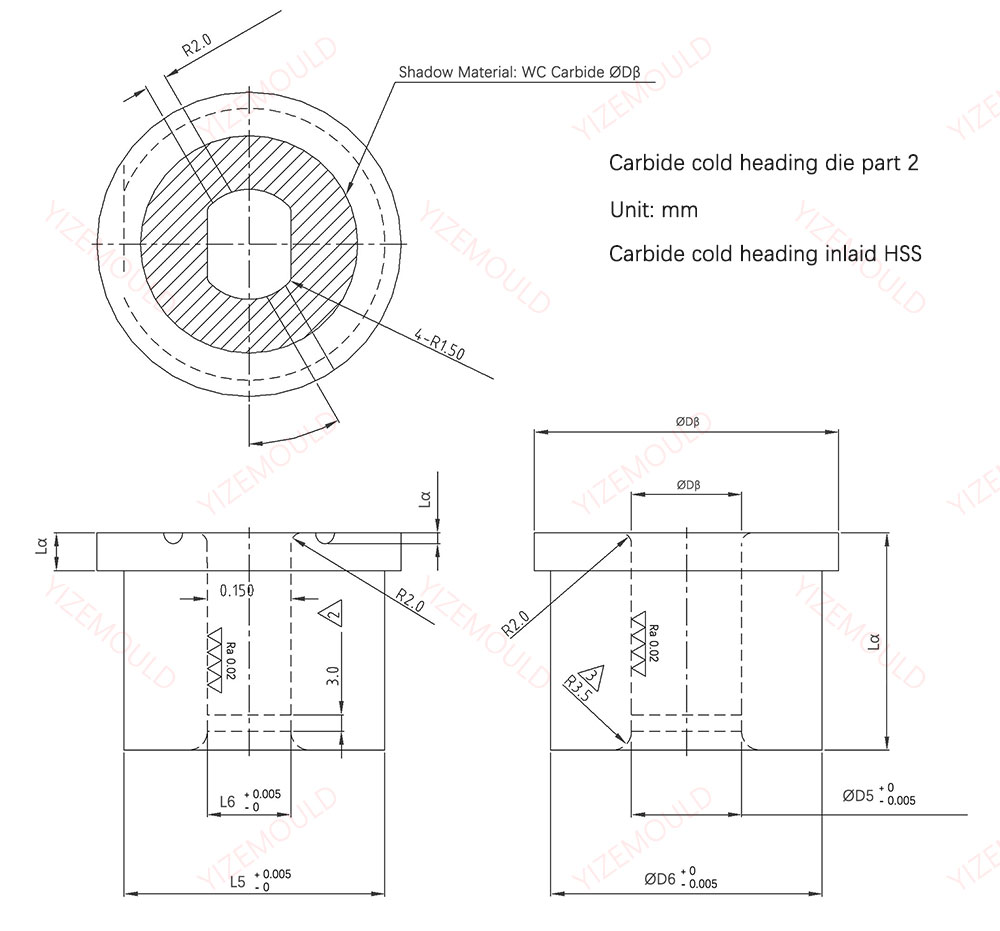

Our expertise spans full-process services including CNC machining, EDM, grinding, polishing, and heat treatment. We serve global clients with high-performance carbide components used in wire drawing, cold heading, stamping, and wear applications.

- ✓ 17+ Years of Industry Experience

- ✓ Advanced CNC & Grinding Equipment

- ✓ ISO-Compliant Quality Control

- ✓ Custom Solutions for Diverse Industries