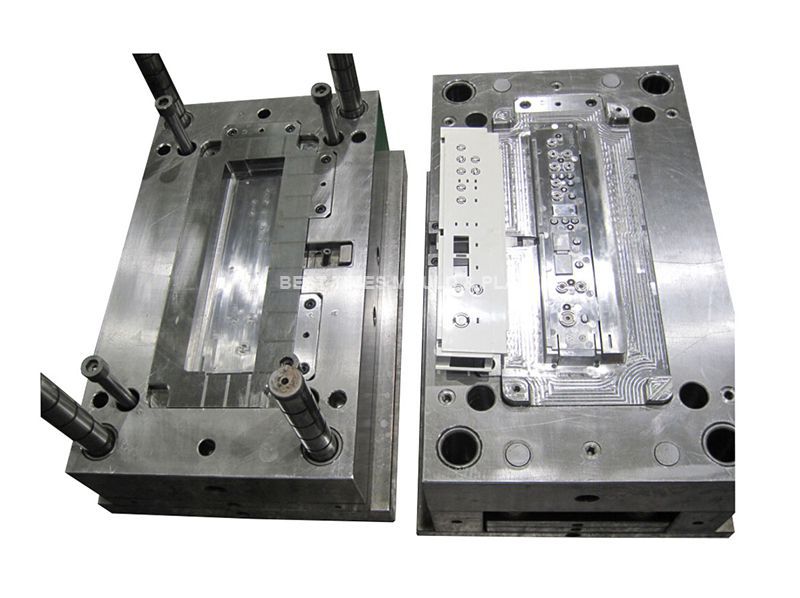

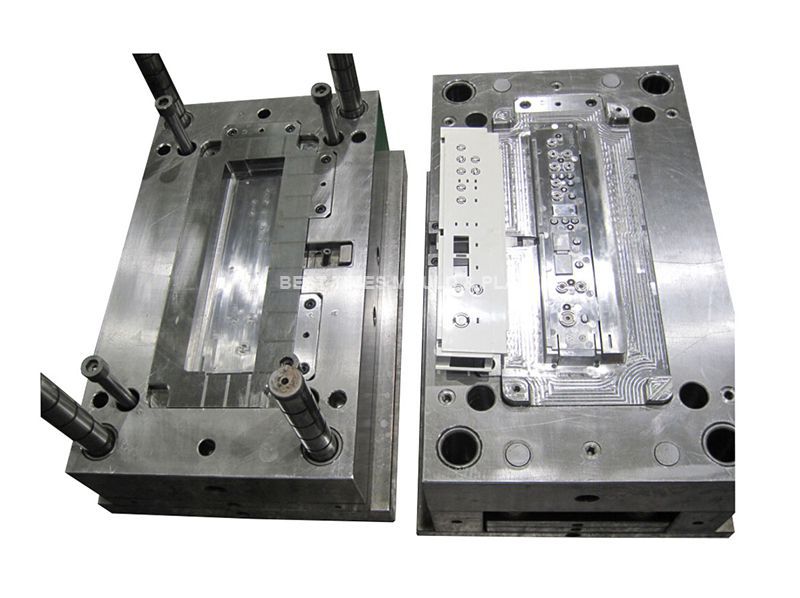

Professional Plastic Injection Mould & Molding Solutions

With over 15 years of experience, Best Times Mould specializes in high-precision plastic injection molds, 2K/3K molding, and custom plastic parts manufacturing for global clients.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

With over 15 years of experience, Best Times Mould specializes in high-precision plastic injection molds, 2K/3K molding, and custom plastic parts manufacturing for global clients.

A Trusted Partner in Precision Mould Manufacturing

Industry Experience

Square Meter Facility

Skilled Employees

Molds Annually

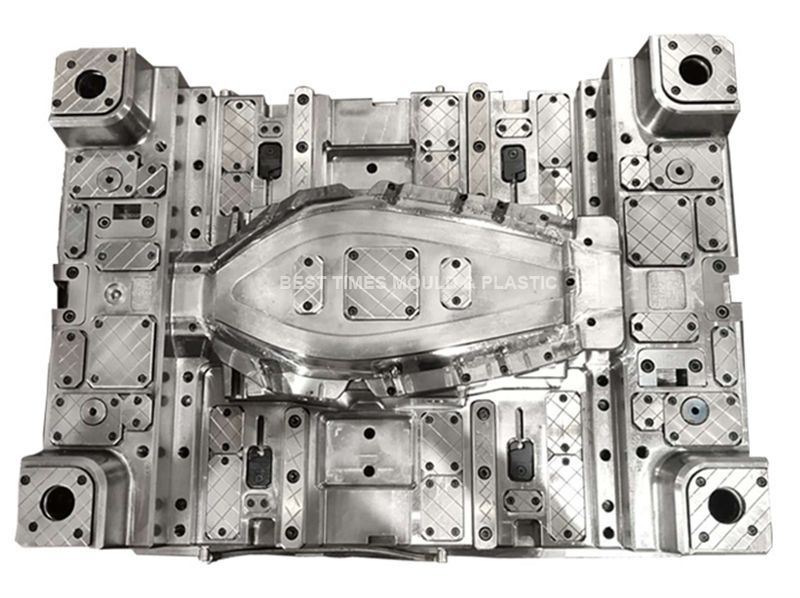

Founded in 2007, we are a professional Chinese manufacturer specializing in plastic injection molds and plastic molded parts. Our expertise spans mold design, precision manufacturing, and full-cycle production support.

We serve industries including medical, automotive, electronics, and consumer goods with OEM and ODM services. Our technical center and quality control systems ensure every product meets international standards.

End-to-End Solutions for Your Plastic Molding Needs

High-Quality Plastic Molds and Molded Parts

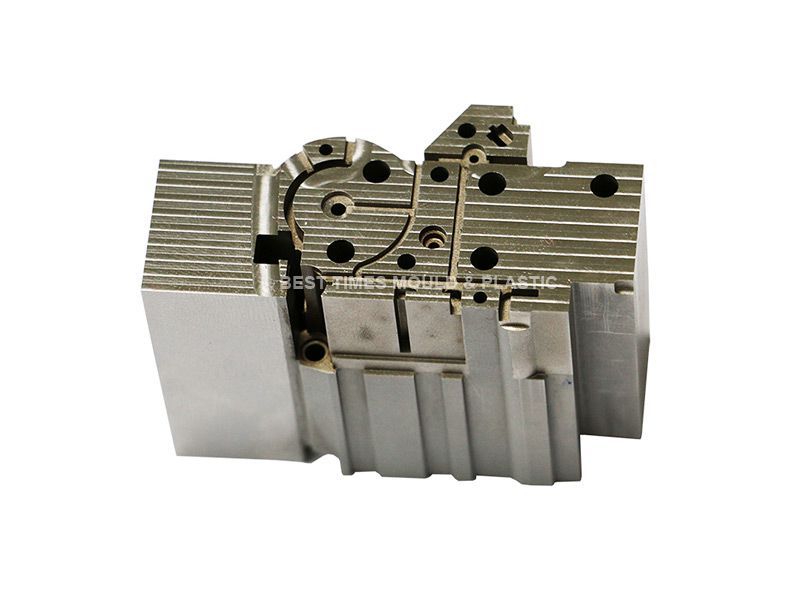

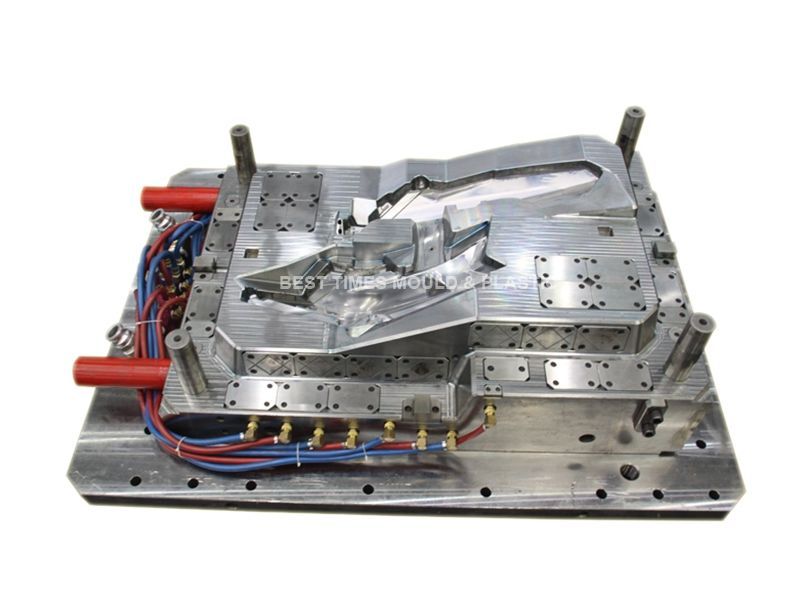

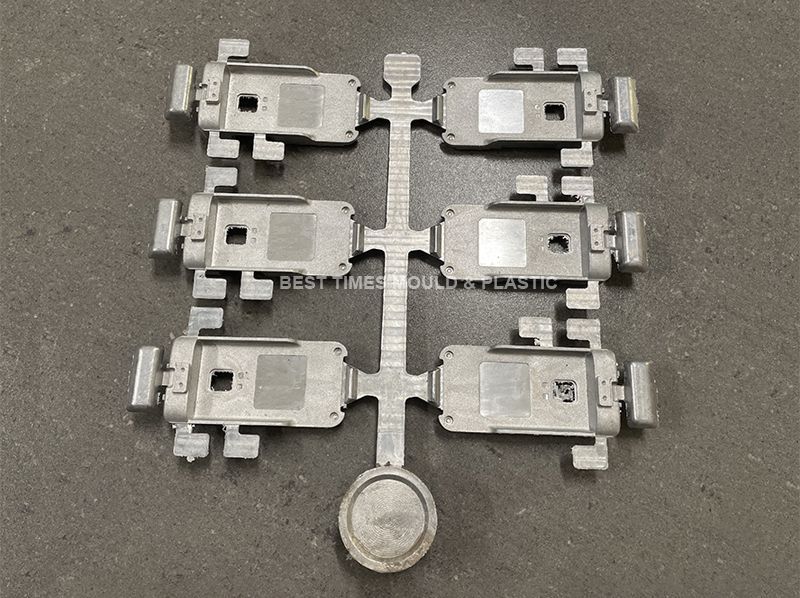

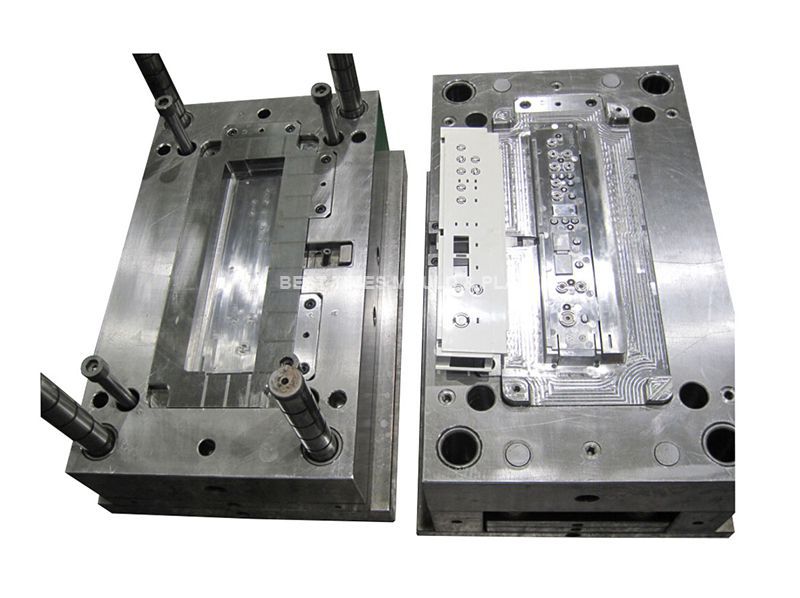

Precision-engineered molds for thermoplastic and thermoset materials. Custom designs with hot runner systems and multi-cavity options.

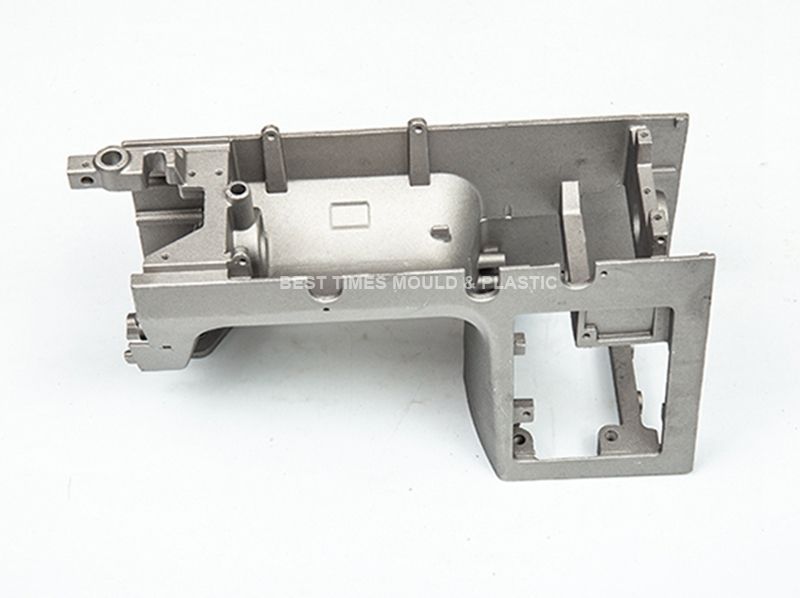

High-volume production of plastic components for automotive, medical, and consumer electronics applications.

Dual-material and dual-color injection molded parts for ergonomic grips, seals, and soft-touch components.

Replaceable mold inserts, sliders, lifters, and sub-components for maintenance and repair.

Complete turnkey solutions from mold design to finished plastic parts with secondary operations.

Custom fasteners, brackets, enclosures, and plastic accessories for industrial and consumer use.

Specialized molds for phenolic, bakelite, BMC, and SMC materials used in electrical and high-temp applications.

High-precision molds for liquid silicone rubber used in medical, food, and automotive sealing applications.

Integration of metal or plastic inserts into molded parts for enhanced strength and functionality.

High-speed production of lightweight, thin-walled plastic containers and packaging.

We process a wide range of thermoplastics (ABS, PC, PP, PE, PA, POM, etc.), thermosets (phenolic, bakelite, BMC, SMC), and liquid silicone rubber (LSR).

Yes, we provide both OEM and ODM services. Our engineering team supports product design, mold development, and full production cycles.

Mold development typically takes 4-8 weeks depending on complexity. Production lead time is 2-4 weeks after sample approval.

We adhere to ISO standards with in-house quality control, including first article inspection, dimensional checks, and material testing.

Yes, we support both low-volume prototyping and high-volume mass production with scalable manufacturing capacity.

Get in touch for a competitive quote or technical consultation

Phone: +86 755 2357 1734

Mobile: +86 189 2287 9832

Email: info@besttimes-mould.com

Email: marketing@besttimes-mould.com

Email: engineering@besttimes-mould.com

Email: quote@besttimes-mould.com

(Free quote within 24 hours)

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info