Our Products

High-quality plastic molds and components engineered for performance, durability, and precision across industries.

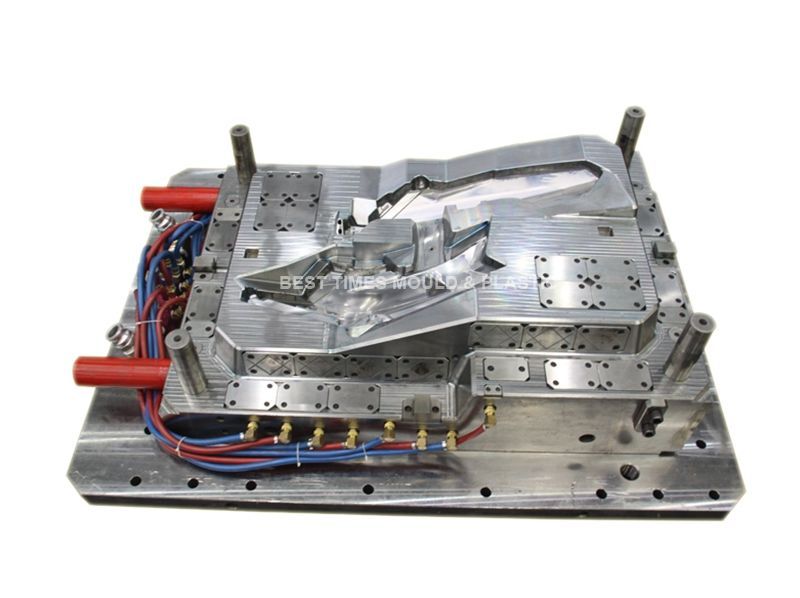

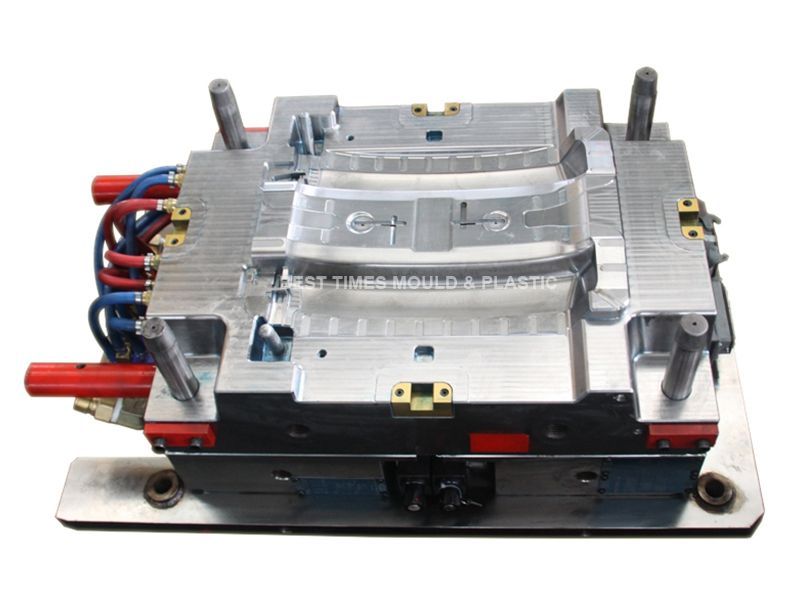

Plastic Injection Molds

Custom-designed molds for thermoplastic and thermoset materials with high precision and long life cycles.

Plastic Molded Parts

High-volume production of complex plastic components with tight tolerances and surface finishes.

Two-Color Plastic Parts

2K and multi-shot molded parts with dual materials or colors for enhanced functionality and design.

Mold Spare Parts & Inserts

Replacement cores, cavities, sliders, and inserts for mold maintenance and repair.

Compression Molds & Parts

High-strength molds and components for SMC/BMC, phenolic, and rubber compression molding.

Hardware & Accessories

Custom fasteners, brackets, enclosures, and plastic hardware for industrial applications.

LSR & Silicone Molds

Liquid silicone rubber (LSR) and silicone injection molds for medical, automotive, and consumer goods.

Precision Mold Components

High-tolerance cores, cavities, lifters, and sliders manufactured with advanced CNC and EDM.