About Zhejiang Changhong

Welcome to Zhejiang Changhong Can End Making Co., Ltd, a professional manufacturer of full-aperture tinplate easy open ends since 1993. With decades of experience and innovation, we have established ourselves as a trusted name in the global packaging industry.

Our advanced production lines integrate world-class machinery including American MINSTER high-speed presses (STI & DRT), SLAC jimould systems, English CMB lining spray machines, and Taiwan SHIN-I machinery equipped with American NORDSON spray guns.

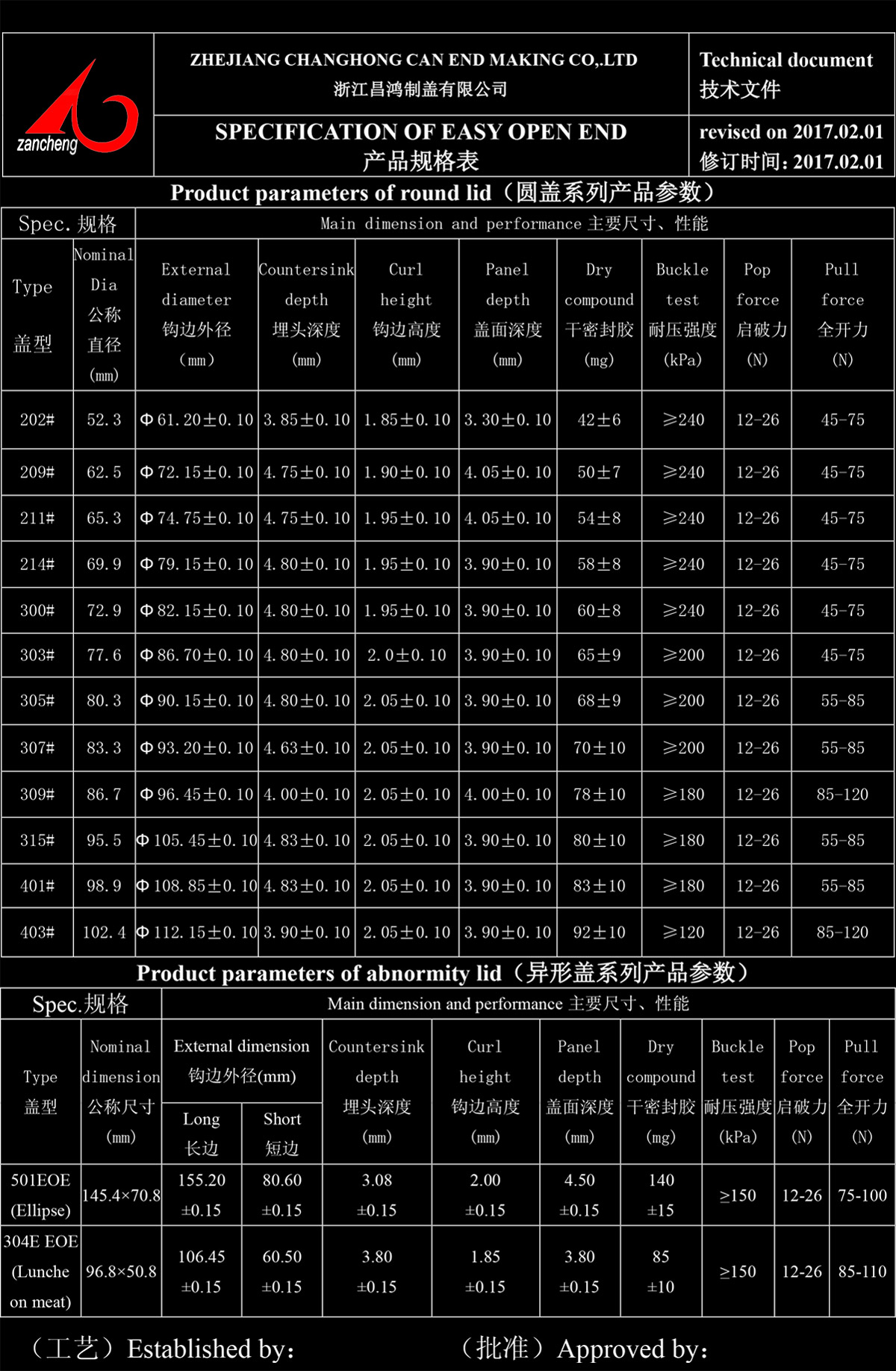

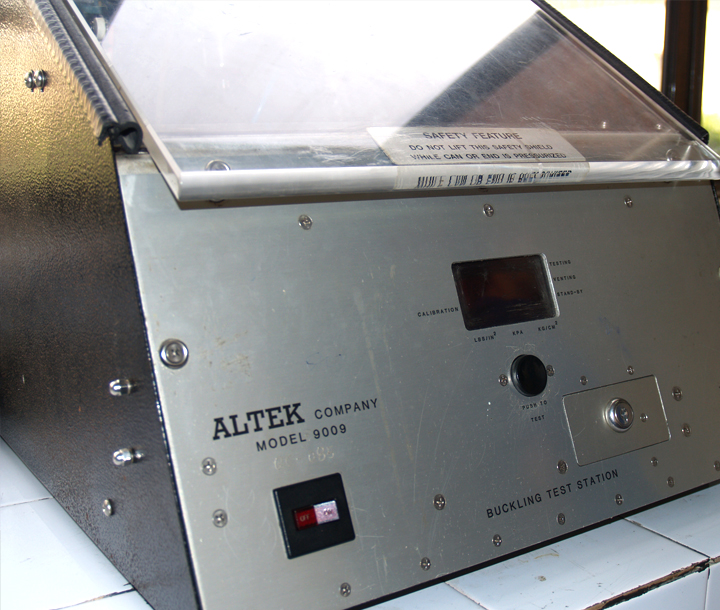

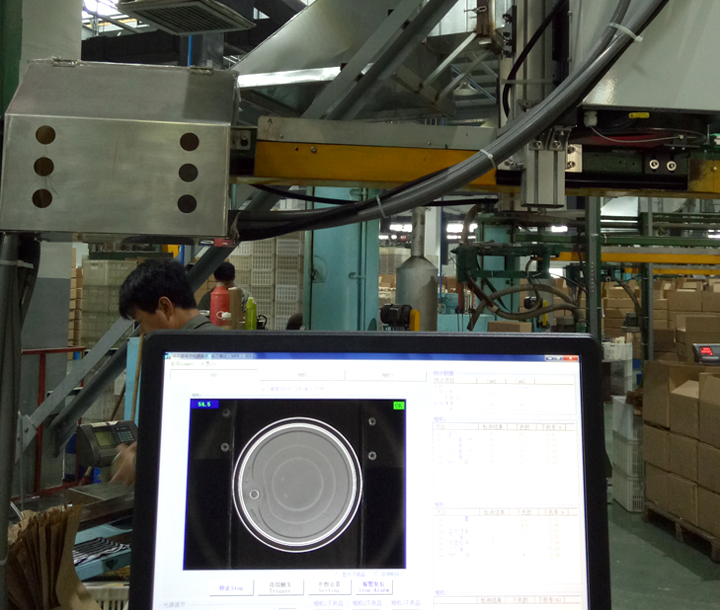

We maintain strict quality control throughout the manufacturing process, ensuring every easy open end meets international standards for performance, safety, and reliability.

- Founded in 1993

- Over 1 Billion Units Annual Output

- ISO-Level Quality Control

- Exporting Worldwide