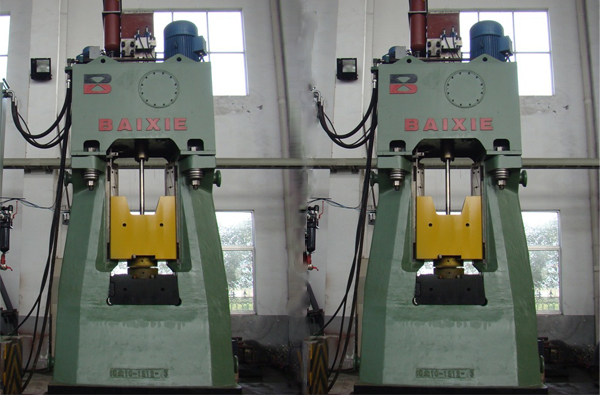

Baixie Forging Hammer & Green Forging Equipment

Premium forging hammers and auxiliary equipment for industrial forging lines. Engineered in China for durability, precision, and unmatched performance.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Premium forging hammers and auxiliary equipment for industrial forging lines. Engineered in China for durability, precision, and unmatched performance.

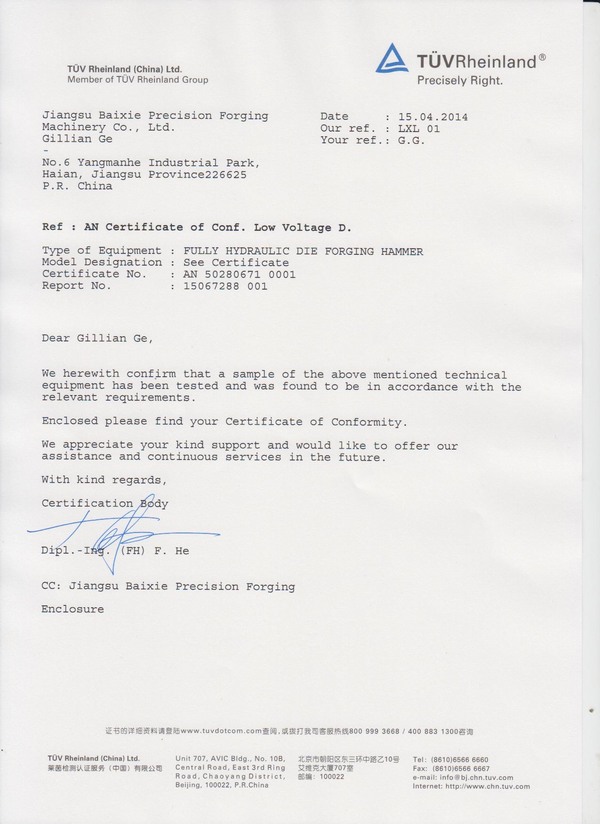

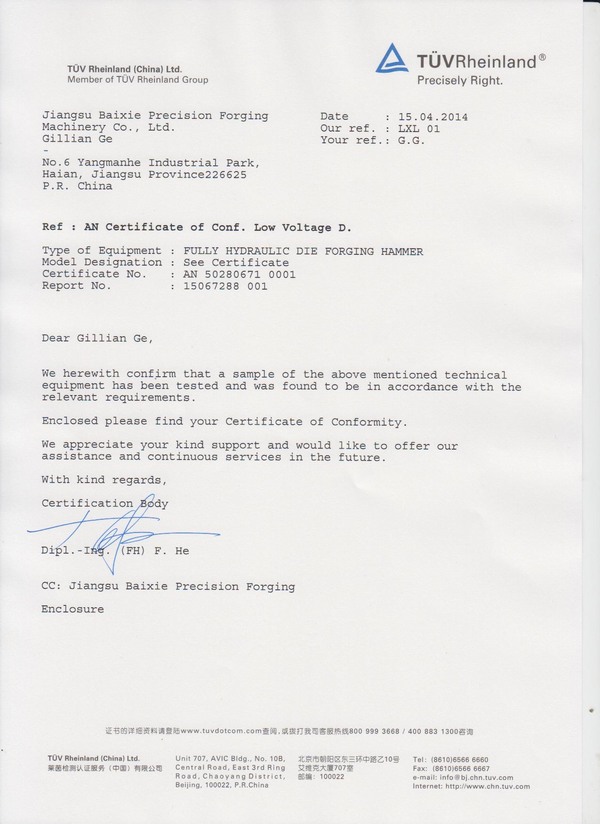

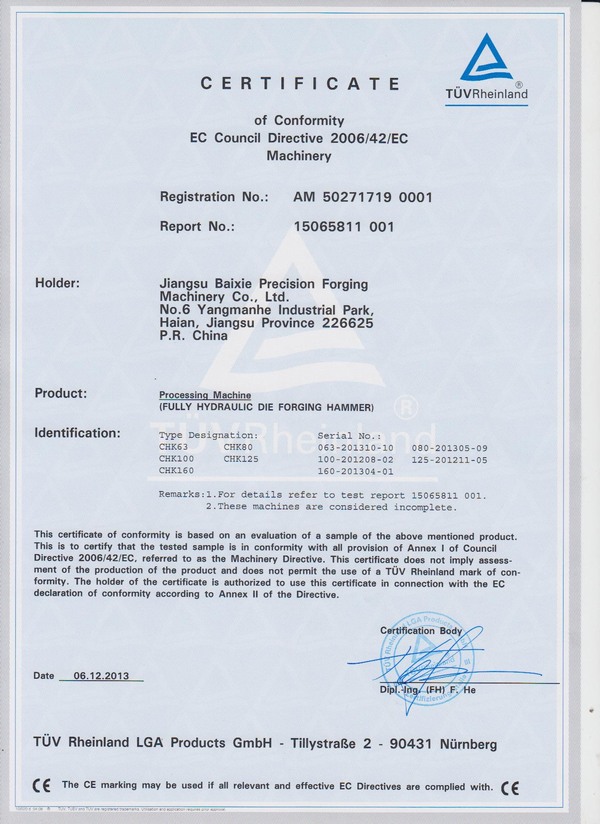

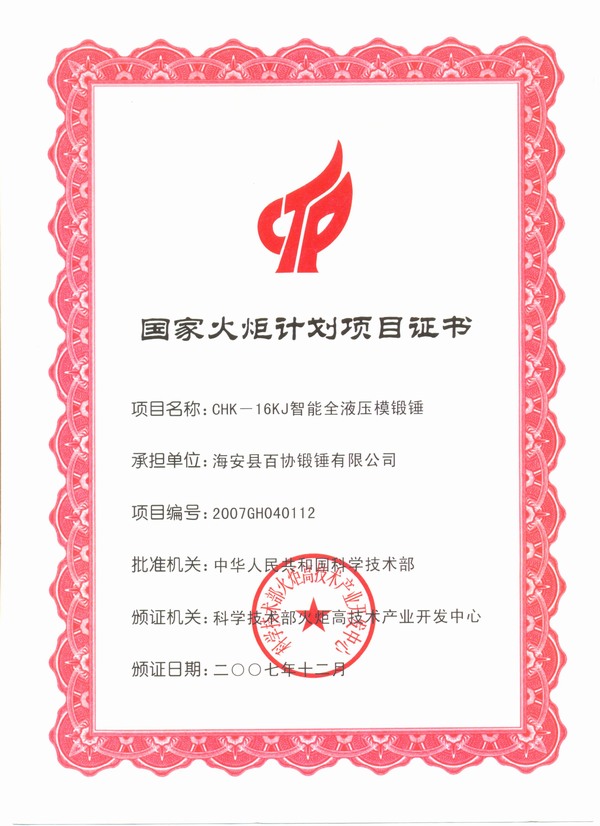

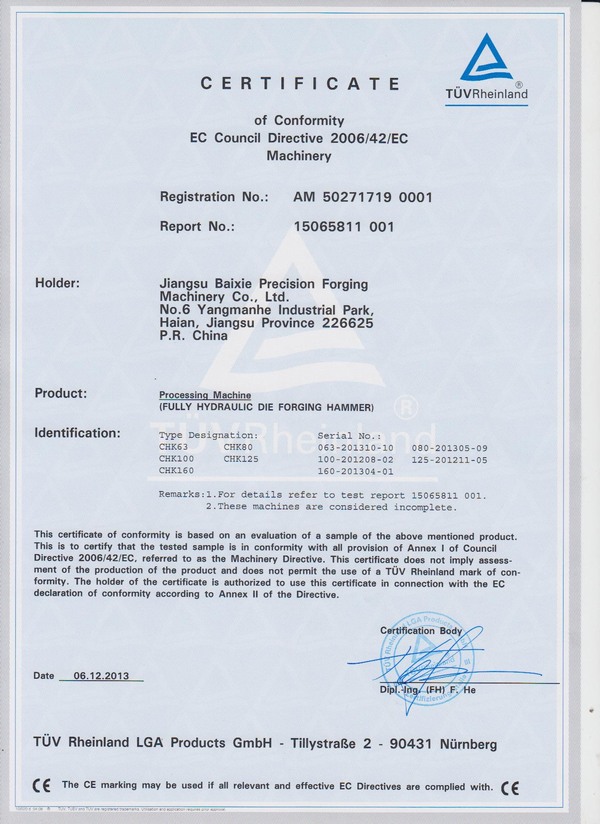

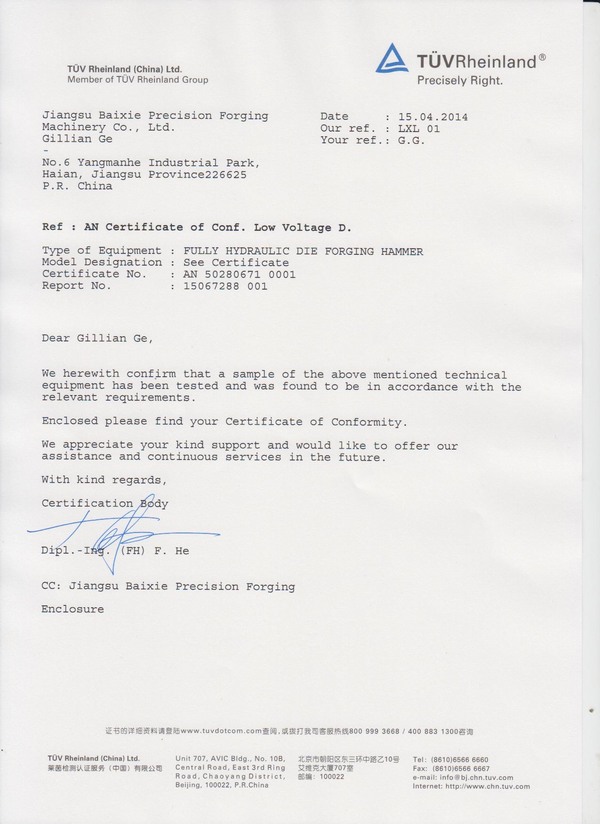

Baixie Forging Hammer is a leading manufacturer and exporter of high-performance forging hammers and auxiliary equipment for forging lines. Based in China, we specialize in producing robust, energy-efficient, and environmentally friendly forging solutions that meet international industrial standards.

Our products are designed for reliability and long-term performance in heavy-duty industrial environments. With years of engineering expertise, we serve clients in automotive, aerospace, construction, and machinery sectors worldwide.

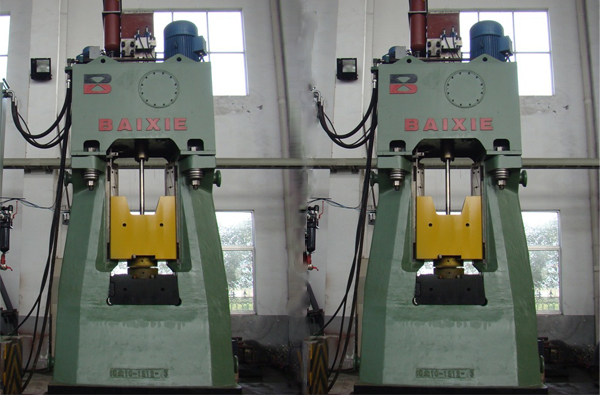

Explore our range of forging hammers and auxiliary equipment designed for maximum efficiency, durability, and precision in industrial applications.

High-speed pneumatic hammer for precision forging operations. Ideal for small to medium-scale production.

Heavy-duty hydraulic system for high-impact forging. Suitable for large components and industrial use.

Automated conveyor system for seamless integration into forging production lines.

High-tolerance die mounting system for consistent forging results and reduced downtime.

Ergonomic handling tools for safe and efficient manipulation of hot metal billets.

Integrated cooling system for post-forging heat treatment with temperature control.

Automated billet feeding system for consistent material input and improved safety.

Protective shielding for operators with noise reduction and heat insulation.

We combine advanced engineering with decades of forging expertise to deliver reliable, efficient, and innovative solutions.

Precision design and simulation-tested performance for optimal efficiency.

Energy-efficient systems with reduced emissions and noise pollution.

Built with high-grade materials for long service life in harsh environments.

Worldwide shipping and technical support for seamless integration.

We offer air hammers, hydraulic hammers, and custom-designed forging systems tailored to your production needs.

Yes, our equipment is designed for seamless integration into automated production lines with PLC control options.

We offer remote guidance and documentation. On-site support can be arranged upon request.

Standard equipment ships within 4-6 weeks. Custom orders may take 8-12 weeks depending on specifications.

Yes, we specialize in custom engineering solutions for unique forging requirements and space constraints.

For product inquiries, technical support, or custom solutions, visit our official website to contact the team.

Visit Official WebsiteNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info