Experts in Pellet Mill Business

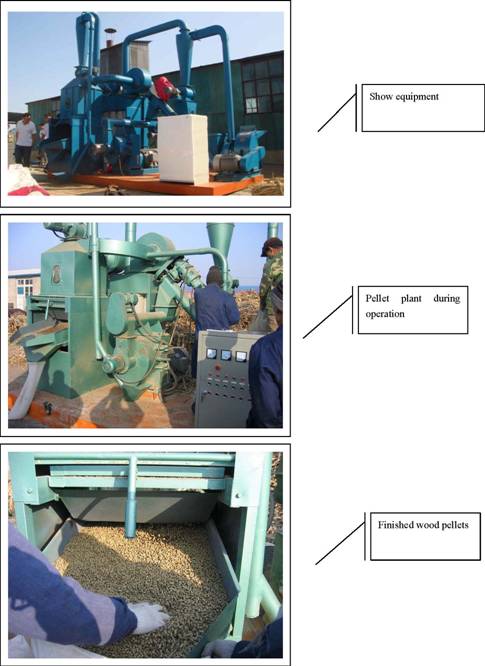

GEMCO, the leader of biomass briquetter and pelletizer manufacturing in China, is a proud member of AGICO GROUP. As one of the first suppliers in wood pelletizer and related biomass processing equipment, we are dedicated to advancing green energy technologies.

Over the past eight years, we've integrated world-class technologies into our machinery, striving to lead China's biomass industry. Our mission — reflected in our name (GREEN ENERGY MACHINERY CO) — is to develop sustainable, high-performance equipment that powers the future of renewable energy.

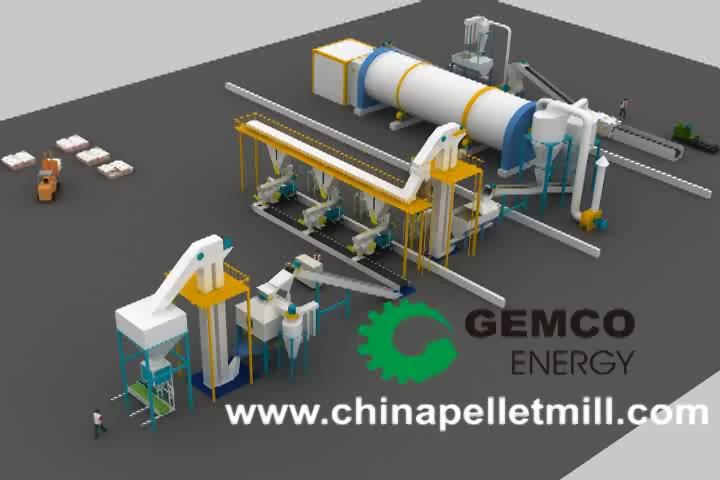

We provide customized biomass projects and complete turnkey solutions, from raw material processing to final pellet packaging.

Our machines are built for durability, efficiency, and continuous operation.