Civen

Civen

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Civen

Civen

Civen Metal Material (Shanghai) Co., Ltd. is a leading manufacturer of high-end copper foil, nickel foil, and laminated materials trusted by electronics, EV, aerospace, and industrial clients worldwide.

Civen Metal Material (Shanghai) Co., Ltd. is a leading company in the production and distribution of high-end metal materials. Established in 2003 in Shanghai, China, we have grown into a significant player in the global metal materials market.

We specialize in manufacturing and distributing a wide range of metal materials, including copper, aluminum, nickel alloys, and laminated materials. Our products are used in aerospace, automotive, electronics, construction, and renewable energy industries.

With a state-of-the-art facility spanning over 22,000 square meters and equipped with advanced machinery, we ensure every product meets international standards including CE, ISO9001, and ISO13485.

We combine advanced technology, rigorous quality control, and customer-focused service to deliver superior metal materials worldwide.

CE, ISO9001, and ISO13485 certified production processes ensure every product meets international standards.

Over two decades of experience in foreign trade export, serving clients in North America, Europe, Asia, and beyond.

22,000+ square meter manufacturing facility equipped with cutting-edge technology for precision production.

Dedicated technical support team provides ongoing assistance, troubleshooting, and application guidance.

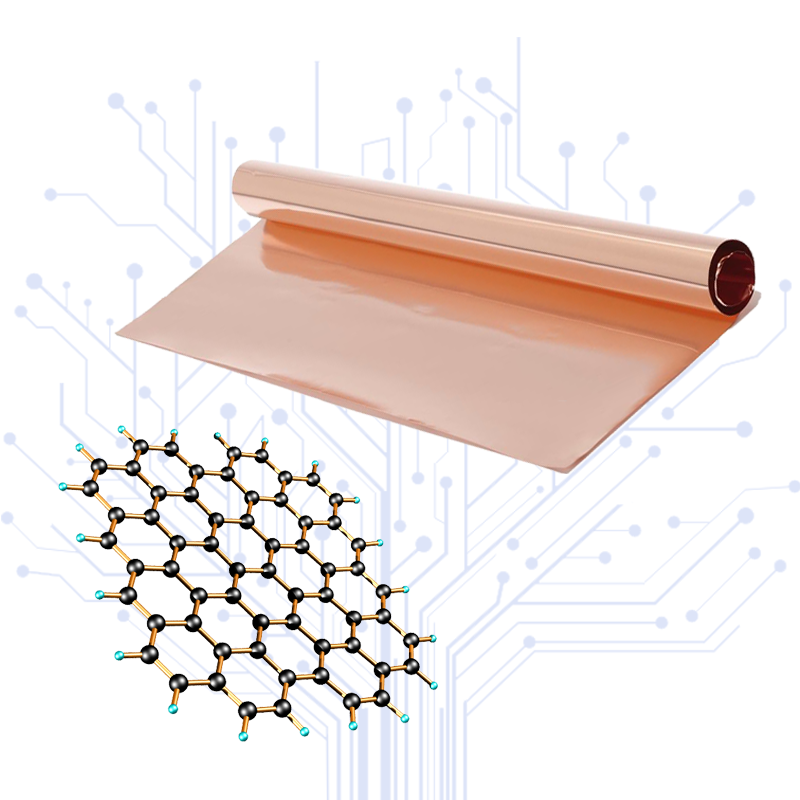

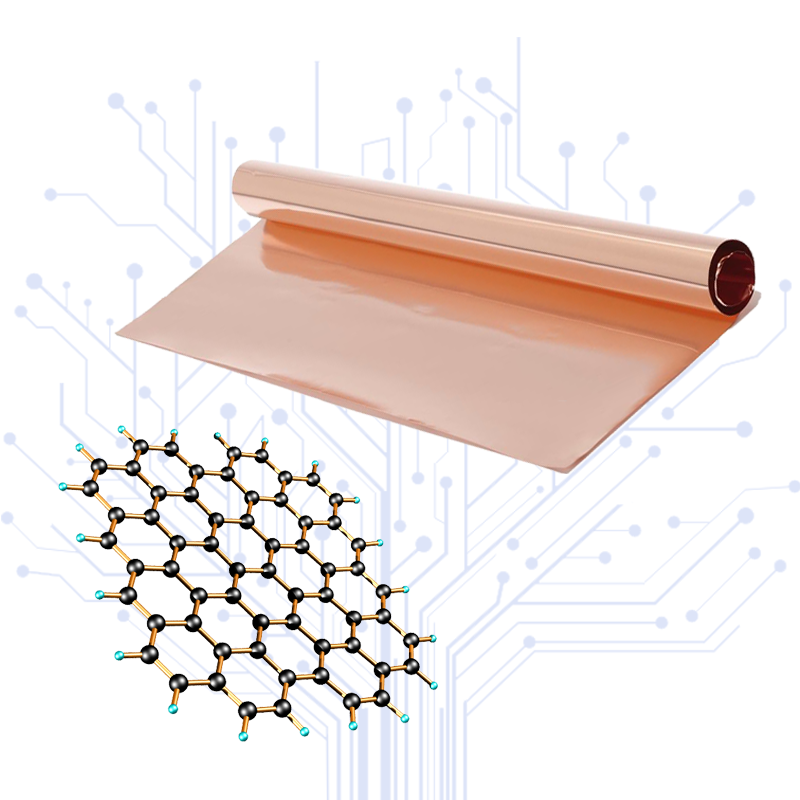

From high-performance copper foils to specialized laminates and alloy strips, Civen delivers precision-engineered metal materials for demanding applications.

Electrolytic copper foil with reverse treatment for enhanced adhesion in high-reliability PCB applications.

High-strength, non-magnetic alloy foil with excellent conductivity and fatigue resistance.

Copper foil with electroless nickel plating for improved oxidation resistance and solderability.

Engineered for flexibility and durability in dynamic applications requiring repeated bending.

Heavy copper foils from 70μm to 400μm for high-current and power electronics applications.

Precision foil designed for uniform heat distribution in EV battery thermal management systems.

Three-layer FPC material with excellent flexibility, adhesion, and dimensional stability.

Surface-treated copper foil with enhanced resistance to oxidation and environmental degradation.

High-purity, soft-annealed copper foil optimized for solar cell interconnection.

High-purity nickel foil produced by electrolysis for precision electronic and industrial uses.

High-precision copper alloy strips for semiconductor packaging and electronic components.

Low-loss, thin copper foils engineered for high-efficiency power conversion systems.

Get answers to common questions about our products and services.

We produce a wide range of copper foils including ED (Electro Deposited) copper foil, RA (Rolled Annealed) copper foil, treated and reverse-treated foils, high-elongation foils, super-thick foils, and specialized variants like nickel-plated and beryllium copper foils.

Yes, our manufacturing processes are certified under CE, ISO9001, and ISO13485 standards. We ensure all products meet rigorous quality and safety requirements for global markets.

Absolutely. We offer customization in thickness, width, temper, surface treatment, and packaging to meet your specific application requirements. Our technical team works closely with clients to deliver tailored solutions.

Our products are used in electronics (PCBs, FPCs), electric vehicles (battery systems), photovoltaics (solar cells), aerospace, telecommunications, medical devices, and industrial equipment.

Standard products are typically shipped within 7–15 days. Custom orders may take 15–30 days depending on specifications. We provide exact timelines during the quotation process.

Reach out to discuss your metal material needs with our technical experts.

For product inquiries, technical support, or custom orders, please visit our official website to submit your request.

Visit Official Website to ContactNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info