About XinYe

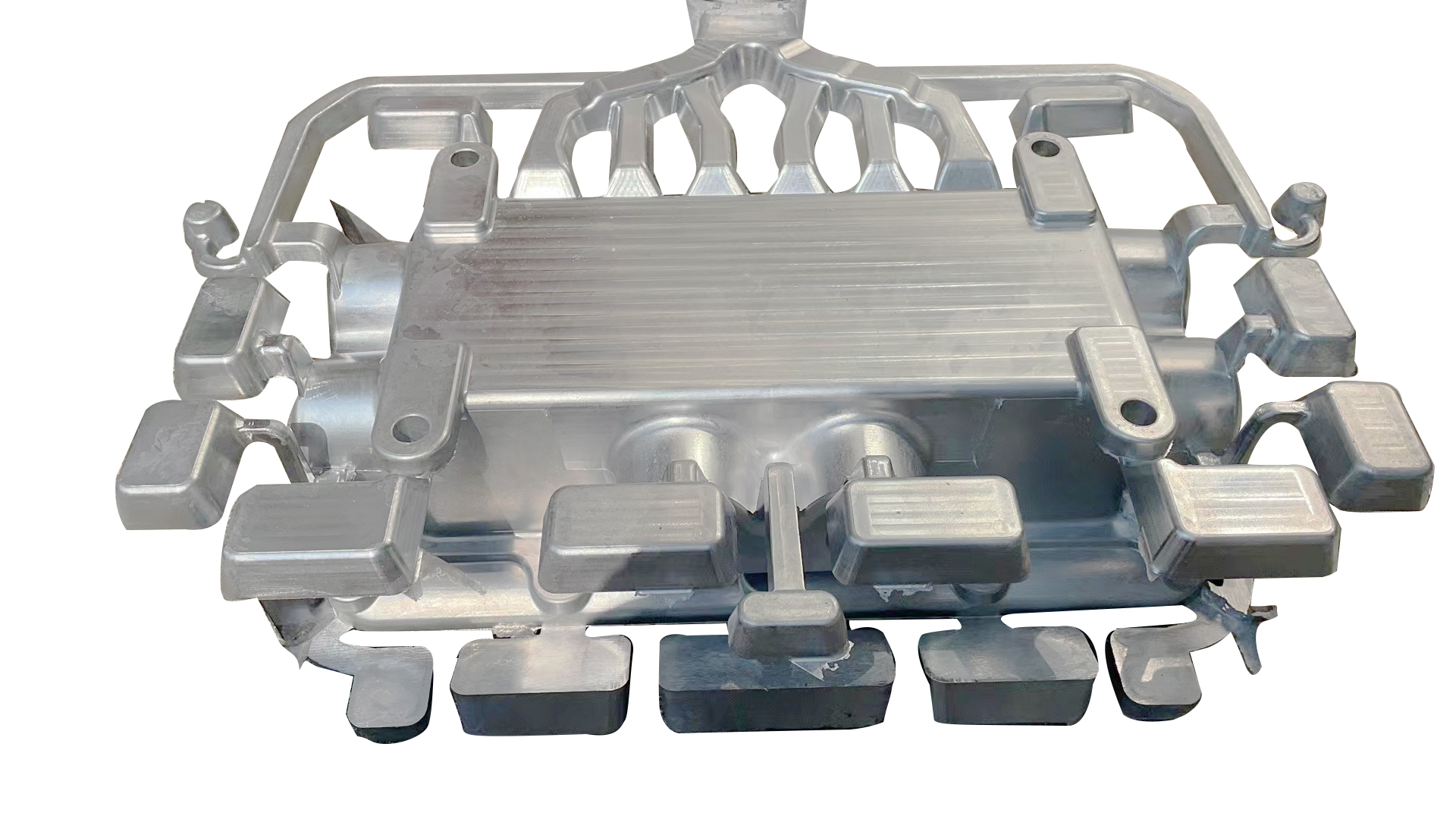

Do you need precision machining services for your technical products? Our factory is tailor-made for businesses that require a full range of services, primarily involving technology, forging, stamping, drawing, machining, surface treatment, and assembly. By choosing our one-stop service, you can expect superior quality, precision, and efficiency at every stage of the manufacturing process.

With over 30 years of experience, we celebrate excellence in engineering and innovation. Our commitment to quality has earned us global recognition and long-term partnerships across industries including aerospace, automotive, energy, and industrial equipment.

- One-stop manufacturing solutions

- ISO-certified production standards

- Advanced CNC and casting technologies

- Global delivery with strict quality control