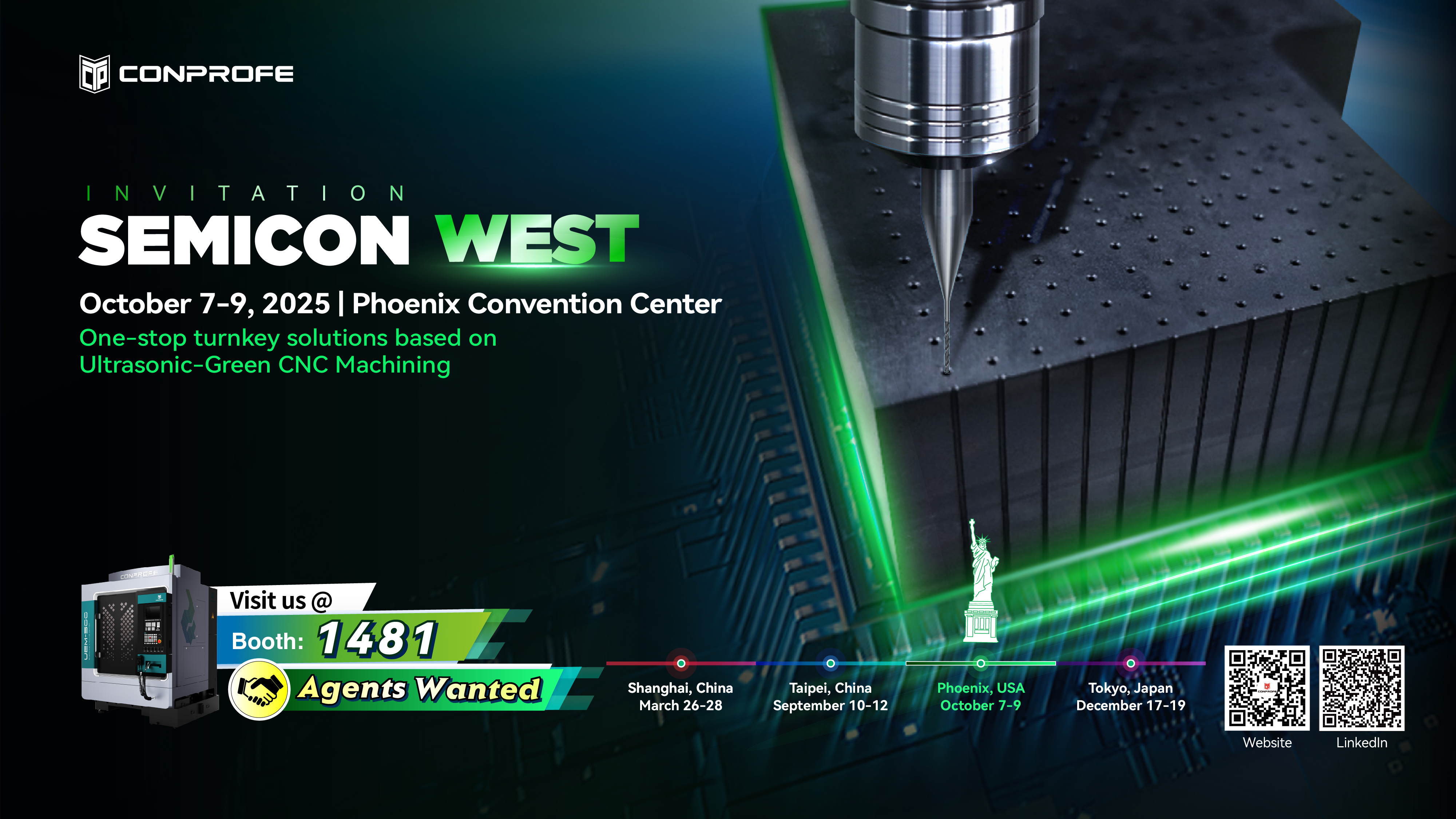

About Conprofe Technology

Conprofe Technology Group Co., Ltd. is a globally recognized innovator in advanced CNC machining solutions. Headquartered in Guangzhou Science City, we have dedicated over 20 years to R&D in ultrasonic-assisted machining, green cooling technologies, and precision tooling systems.

Our mission is to solve industrial challenges—from suppressing microcracks in ceramics to reducing cutting forces and temperatures in titanium and composites—by integrating intelligent design with sustainable engineering.