What is CVD Diamond Coating?

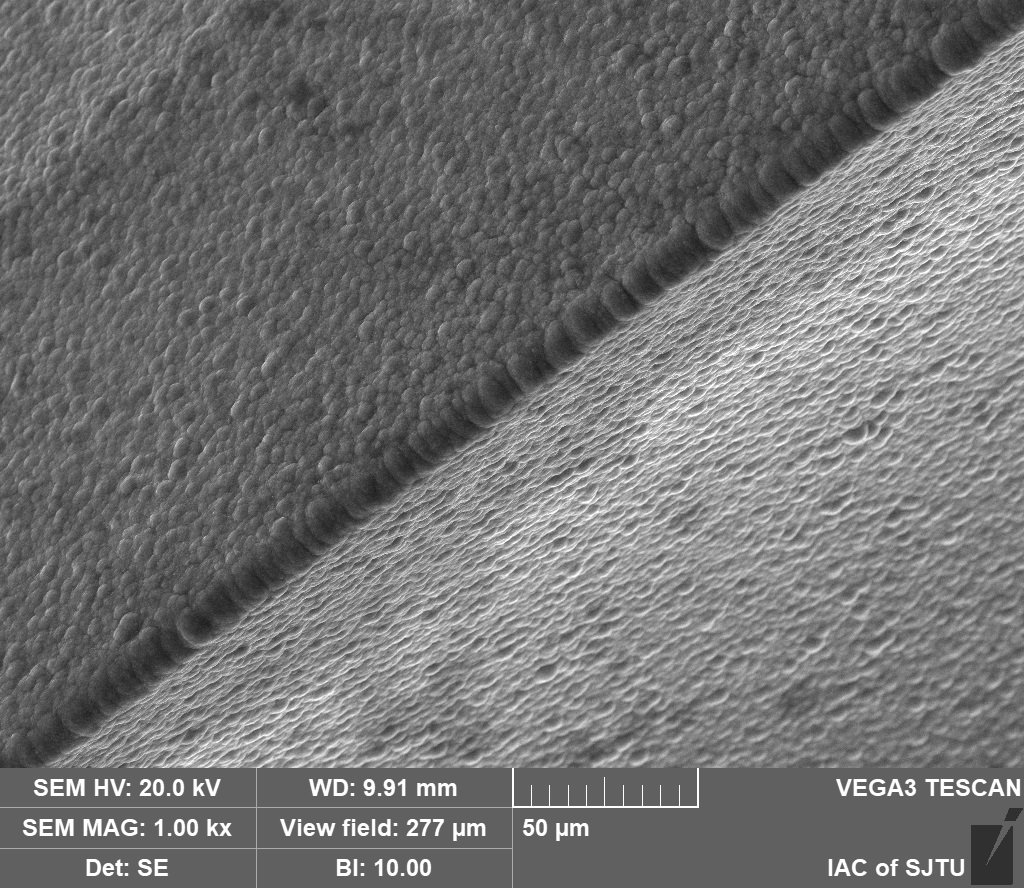

CVD (Chemical Vapor Deposition) Diamond Coating is a high-precision process that deposits a nano-diamond layer of 6 to 16 microns onto a tungsten carbide substrate. The substrate must contain low cobalt content (e.g., 6%) and undergo specialized surface treatment to ensure optimal adhesion.

This treatment reduces cobalt in the outer layer, exposing diamond edges and creating a strong bond between the coating and substrate. CVD technology significantly enhances tool life—up to 20 times longer than uncoated tools—while improving cutting efficiency, speed, and surface finish quality.

Originally used for industrial cutting tools like drills and inserts, CVD is now revolutionizing dental applications such as burs, orthodontic pliers, and tweezers—offering superior performance, safety, and cost-efficiency.