About XIANGYE

Established in 2009, XIANGYE is a high-tech company specialized in engineering, designing, manufacturing, and supplying automated equipment. Our manufacturing plant covers an area of 3,600 m².

We have earned the ongoing trust of our customers with our honesty, expertise, and product quality. In 2017, we made a commitment to innovation and positioned ourselves to serve automated workshops for manufacturing data cables and earphone cables.

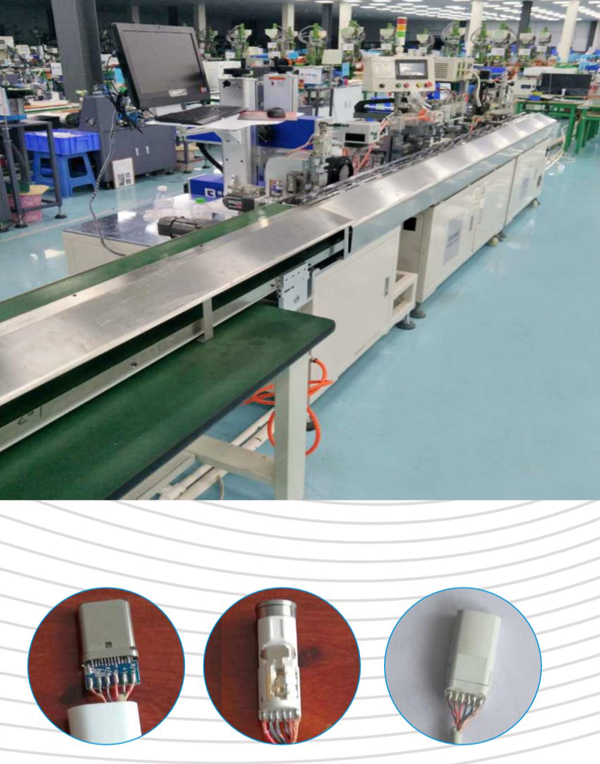

Our goal is to assist customers in reducing labor force and enhancing production efficiency while yielding higher profits. For a workload of producing 10,000 data cables per day, our automatic cable processing equipment can reduce the number of operators from 80 to just 15.

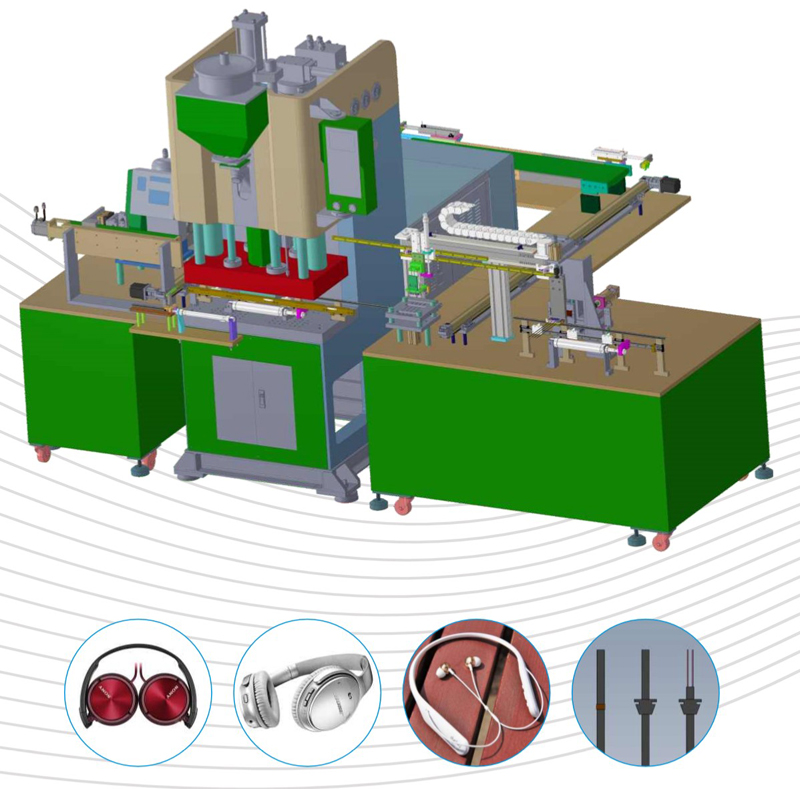

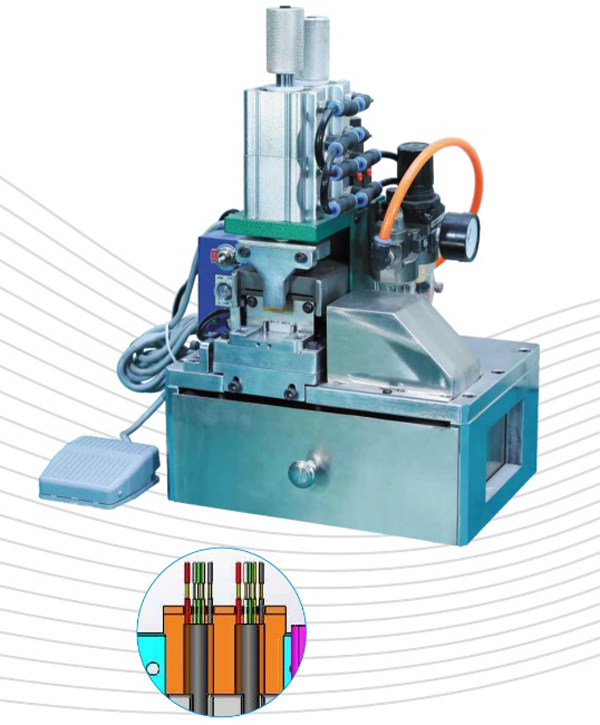

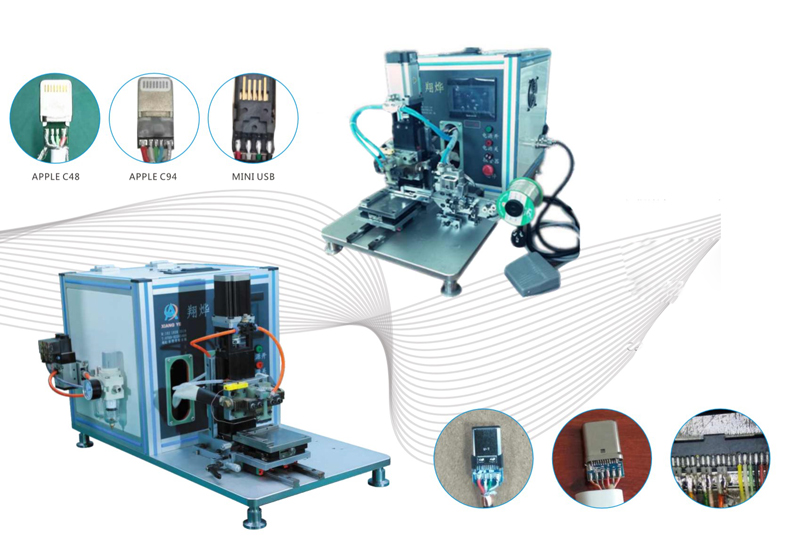

Automated Solutions

Custom cable production lines tailored to your needs

Efficiency Boost

Reduce labor by up to 80% with our machines