About DH Mold

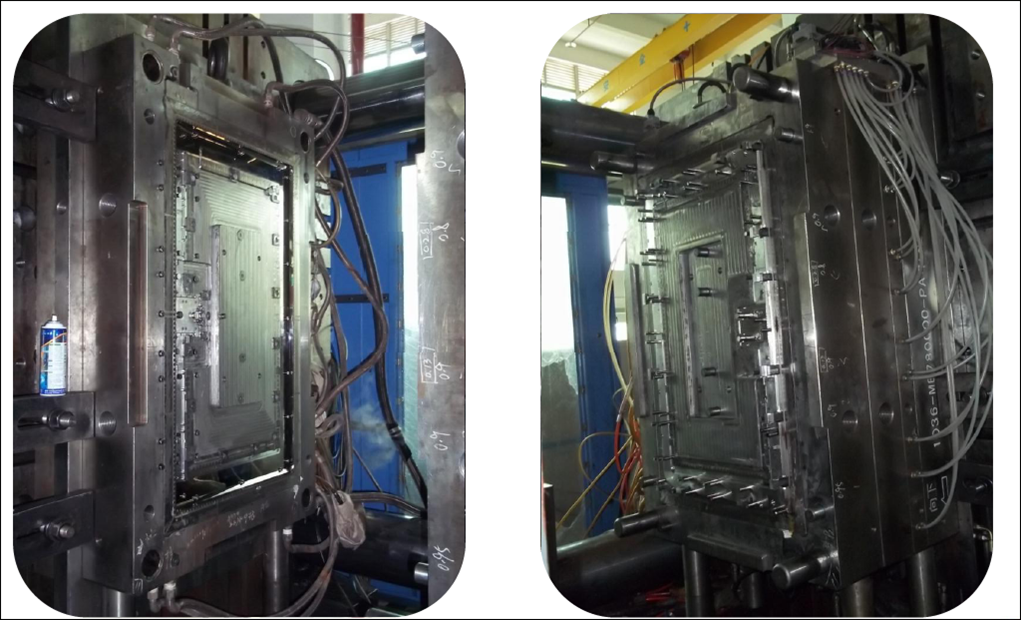

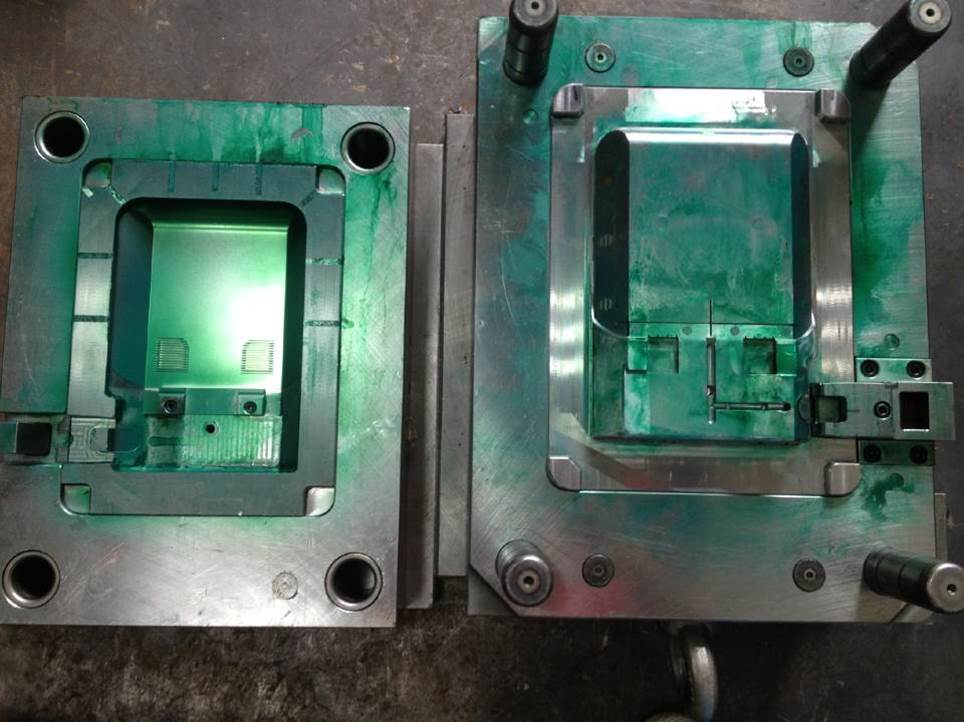

Shenzhen Dehui Mould Co., Ltd. is a leading manufacturer specializing in precision molds and parts. Located in the western part of Shenzhen, adjacent to the beautiful Manhole Sea pastoral scenic area, our factory spans a modern industrial park equipped with advanced manufacturing systems.

We offer comprehensive one-stop services including single/double injection mold design, metal stamping, two-color injection molding, printing, screen printing, and full component assembly. Our expertise ensures high-quality, cost-effective solutions tailored to your industry needs.

- ISO-Certified Manufacturing

- 15+ Years of Industry Experience

- Global Clientele Across Europe & Asia