DERYOUNG

DERYOUNG

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

DERYOUNG

DERYOUNG

Over 20 years of expertise in manufacturing sintered metal parts including gears, bushings, pistons, and structural components for global industries.

DERYOUNG Technology is a preferred supplier for leading automotive, industrial, and mechanical engineering companies worldwide.

DERYOUNG Technology Development (Heyuan) Co., Ltd. is a professional metal parts manufacturer with over 20 years of experience in the development and production of sintered metals.

We specialize in manufacturing oil bearings, transfer case motor gears, shock absorber pistons, sintered bushings, damper guides, bottom valves, actuator gears, and custom metal parts using advanced powder metallurgy techniques.

Expertise in powder metallurgy and sintered metal components.

Best quote provided within 1 working day after receiving drawings or samples.

Powder metallurgy reduces manufacturing costs with high efficiency and minimal material loss.

Serving clients in Europe, North America, Asia, and beyond.

Pistons, rod guides, and bottom valves manufactured via powder metallurgy for cost efficiency and reliability.

Self-lubricating copper and iron bushings with oil impregnation, ideal for mechanical and electrical applications.

Powder metallurgy gears for power tools, actuators, and transfer cases — low cost, high durability.

Custom sintered metal components for industrial applications where precision and strength matter.

2 Drive to 4 Drive conversion gear for automotive applications.

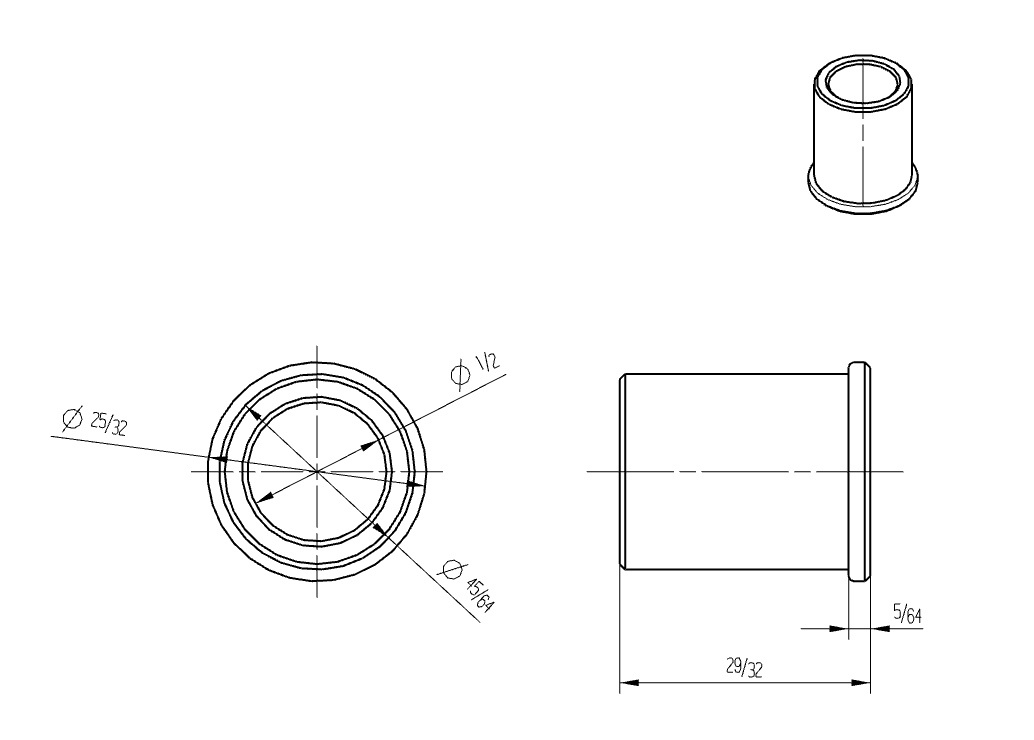

Dimension: 1/2 in ID × 45/64 in OD × 29/32 in L

Inner Diameter: 28.5 mm

11 mm ID × 13 mm OD × 6.7 mm L

8 mm ID × 12 mm OD × 10 mm L

5 mm ID × 8 mm OD × 10.8 mm L

Precision sintered piston for automotive suspension systems.

Sintered metal valve for hydraulic dampers and shock absorbers.

Over 20 years of industry experience with engineering standards compliant with ISO9001:2008, national, and American standards.

Customizable solutions with free prototyping. Our engineers refine formulas and designs to meet your exact specifications.

4 imported German production lines with 800 tons/month capacity. Fast sampling (2 days) and delivery (3–5 days).

Years of Experience

Tons Monthly Output

Day Fast Quotation

Days Delivery Time

Powder metallurgy is a manufacturing process that involves compacting metal powders into a desired shape and then heating them to bond the particles. It allows for high material efficiency, complex geometries, and cost-effective mass production.

Also known as oil-impregnated bearings, these are self-lubricating bushings made from porous sintered metal that retains oil. They require no external lubrication and are ideal for maintenance-free applications.

Yes. We offer full customization. Send us your drawings or samples, and we’ll provide a quote within one business day. We support prototyping and small to large batch production.

We serve automotive, industrial machinery, power tools, HVAC, robotics, and consumer electronics industries with precision sintered metal components.

Whether you need a quote, sample, or technical consultation, our team is ready to assist you with your powder metallurgy component needs.

Visit Official Website to ContactNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info