About DF-Mold

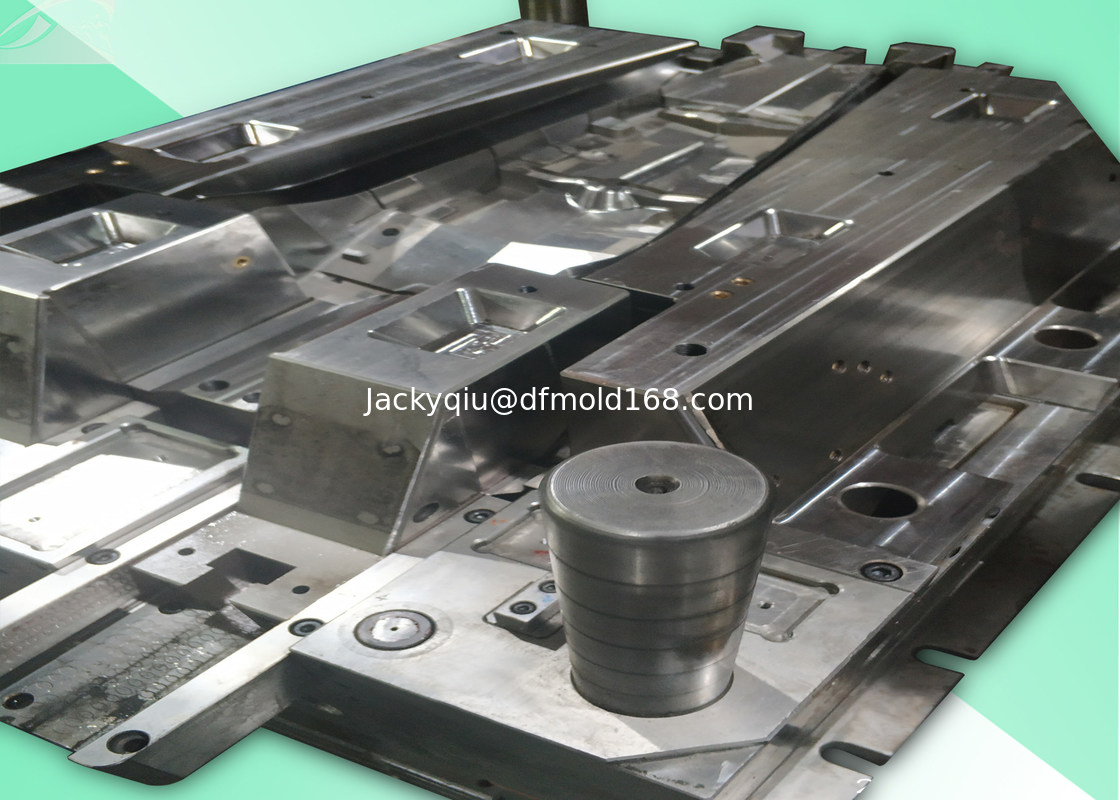

Dengfeng Mold (Hongkong) Co., Limited is a leading injection mold manufacturer based in Sihui, Guangdong, China. We specialize in high-precision plastic injection molding, automotive mold manufacturing, and custom mold design with advanced capabilities including mold flow analysis, hot runner systems, and thin-wall molding.

Our expertise spans across industries such as automotive, home appliances, medical, and consumer electronics. With strict quality control systems and a professional testing lab, we ensure every mold meets international standards.