Trusted Precision Engineering Since 2006

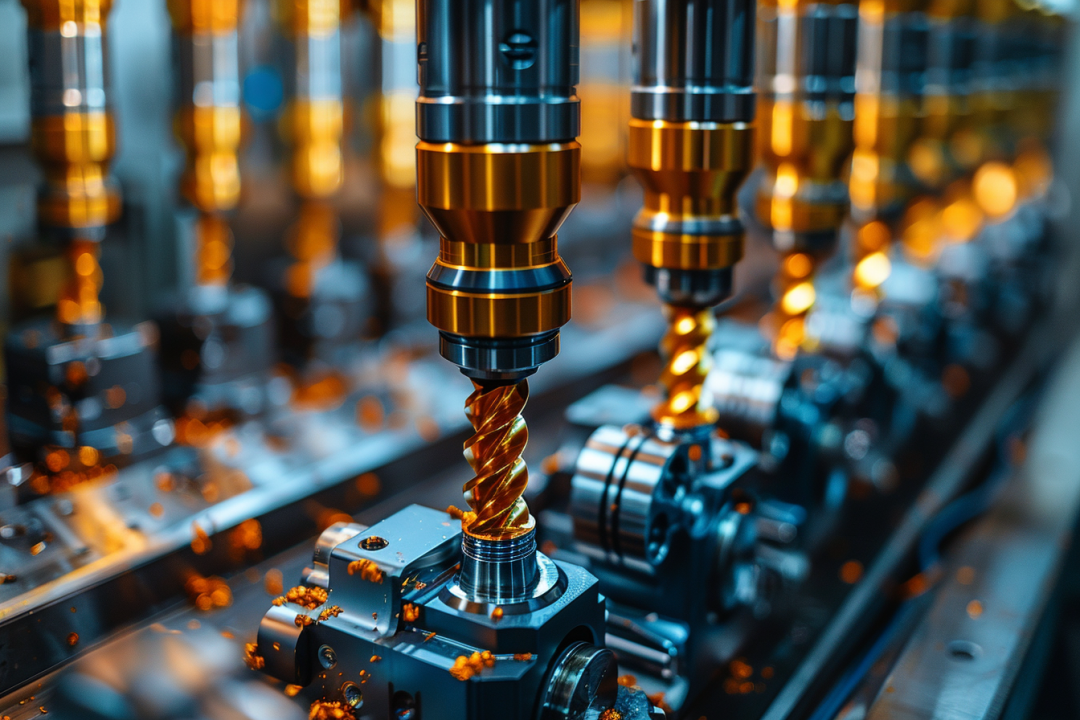

Dongguan Mingte Hardware Machinery Co., Ltd. is a leading manufacturer specializing in high-precision CNC machining, OEM machinery parts, lathe machining, and custom metal & plastic components. With over two decades of industry experience, we deliver exceptional quality and reliability for global clients.

Our advanced facility in Dongguan is equipped with state-of-the-art inspection systems, senior technicians, and a highly qualified R&D team dedicated to meeting the most demanding engineering specifications.