About Zhejiang ZENDA

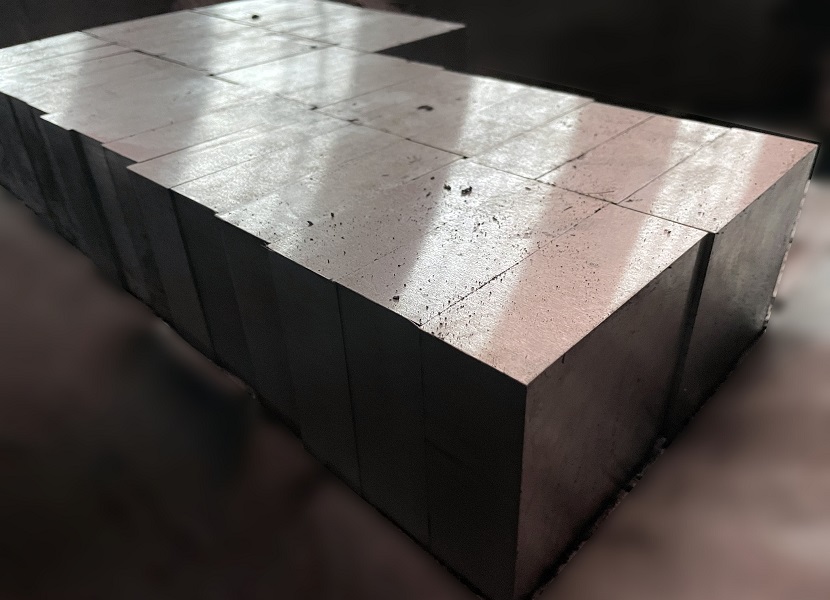

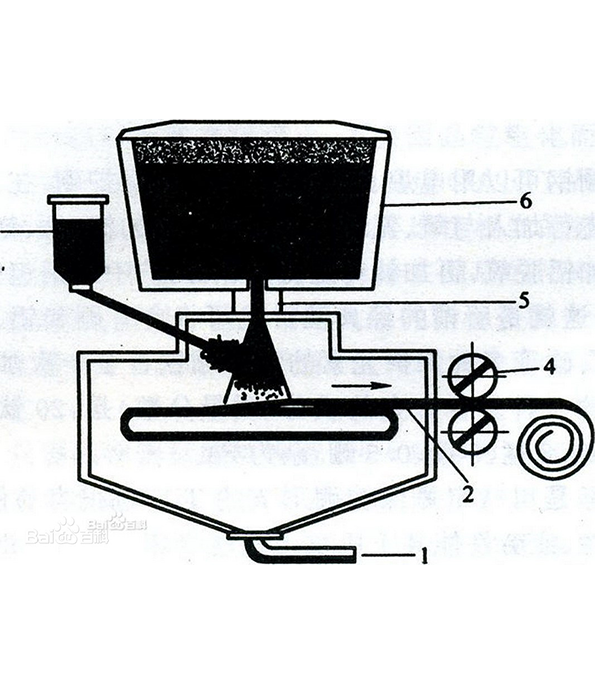

A leading innovator in advanced material technology, integrating smelting, spray forming, electroslag remelting, forging, and finishing.

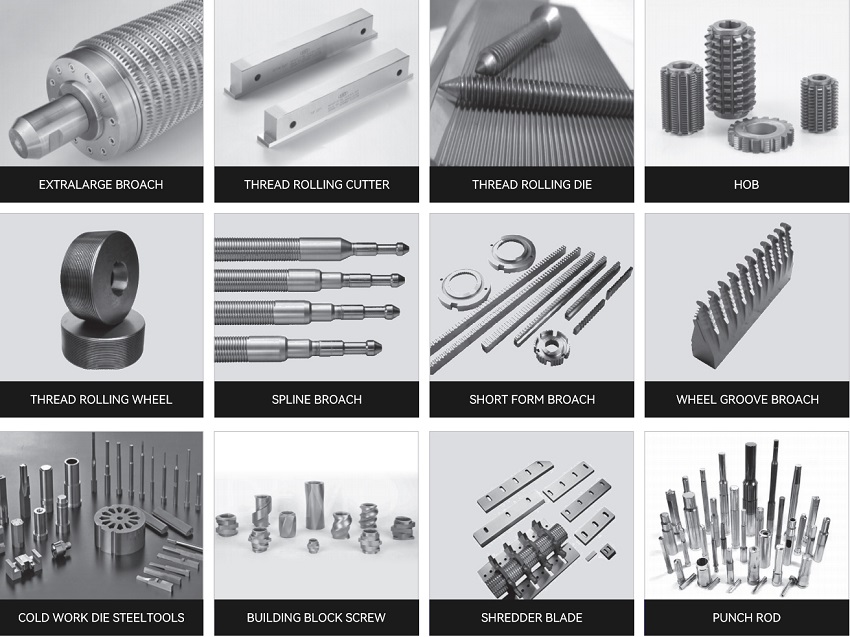

Zhejiang ZENDA Advanced Material Technology Co., Ltd. integrates smelting, spray forming, electroslag remelting, forging, hot rolling, cold drawing treatment, and finishing. Relying on decades of scientific and technological resource reserves and market competitiveness from its parent company, Zhejiang Zhengda Mold Co., Ltd., it acquired Zhejiang Yisheng Special Tool Mold Co., Ltd., specializing in the research, development, and manufacture of high-performance tool and die steel.

Our brands “EST” and “Yishengte” are trusted by customers in more than 40 countries and regions. With a strong foundation in metallurgical innovation and manufacturing excellence, we deliver materials that meet the highest global standards.