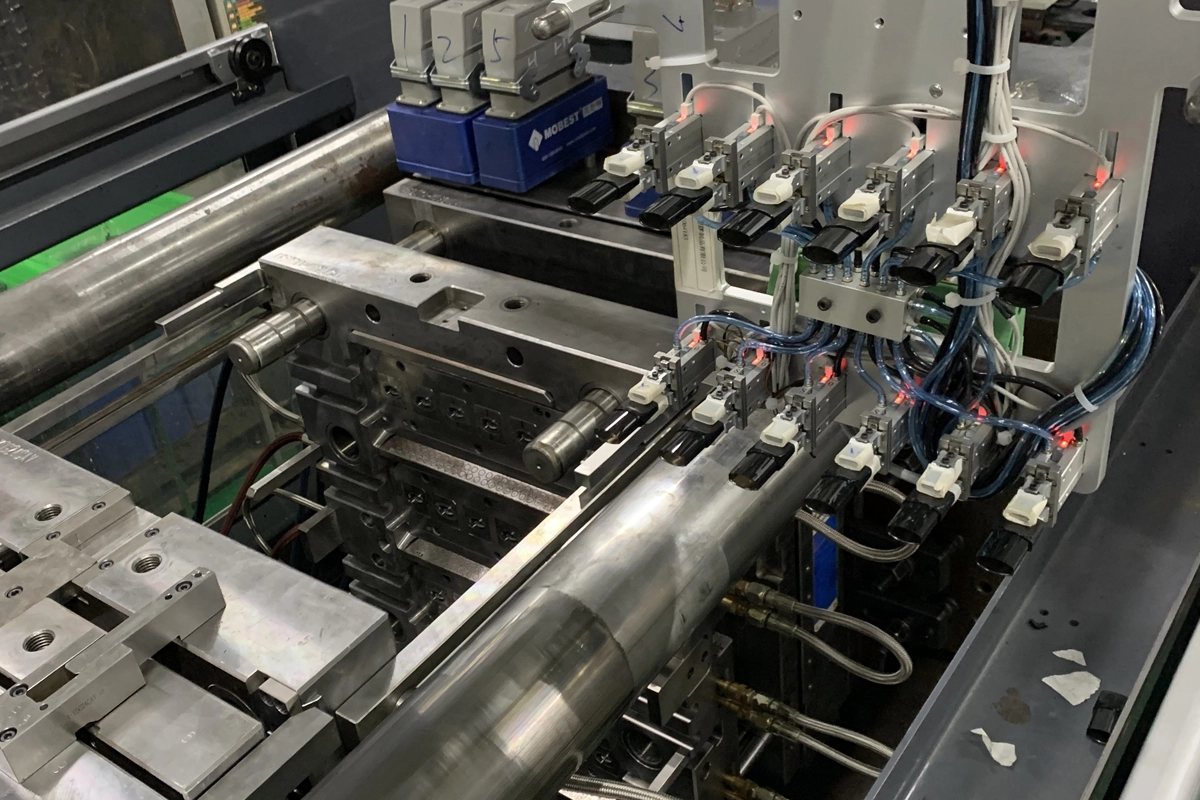

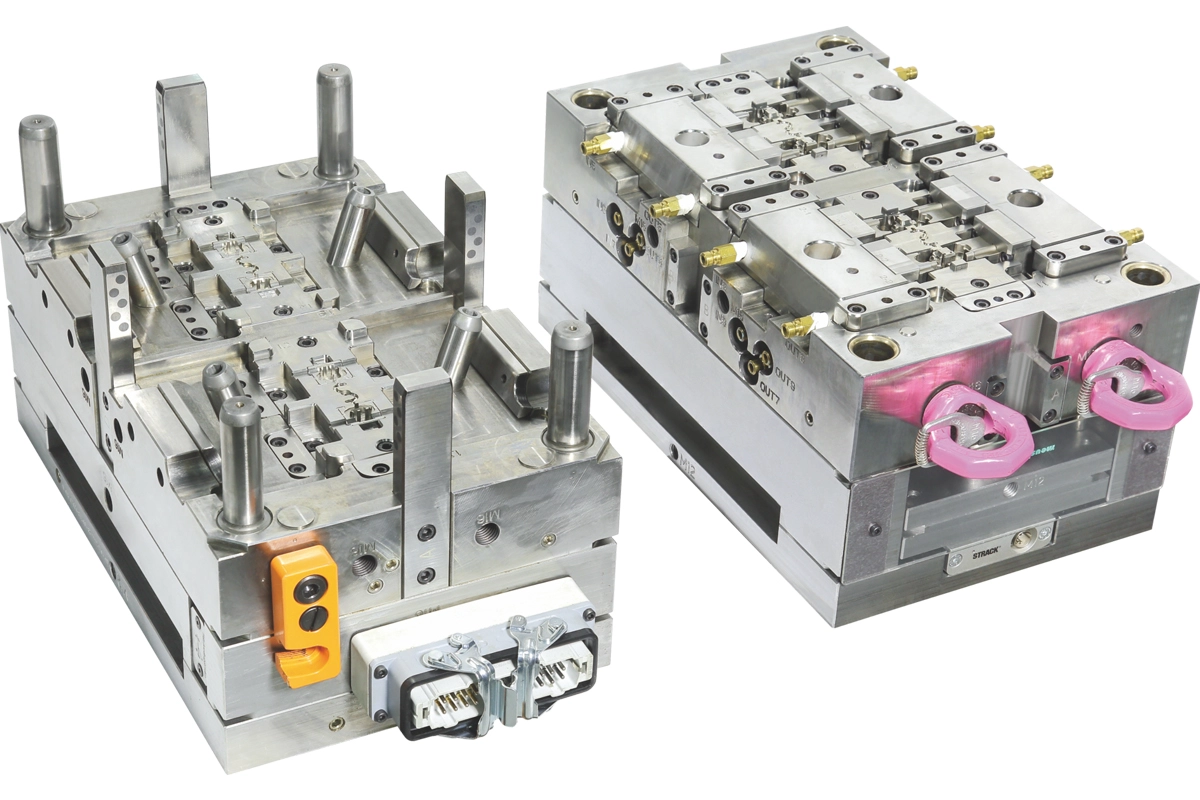

Trusted Precision Molding Expertise

Fangling is a leading precision injection mold manufacturer based in Dongguan, China. With years of experience in mold design and manufacturing, we specialize in delivering high-quality molds and components for industries ranging from automotive and medical to consumer electronics and packaging.

Our commitment to innovation, quality assurance, and customer satisfaction has positioned us as a reliable partner for global clients seeking precision, durability, and cost-effective solutions.

100+

Mold Projects Delivered

15+

Years Industry Experience