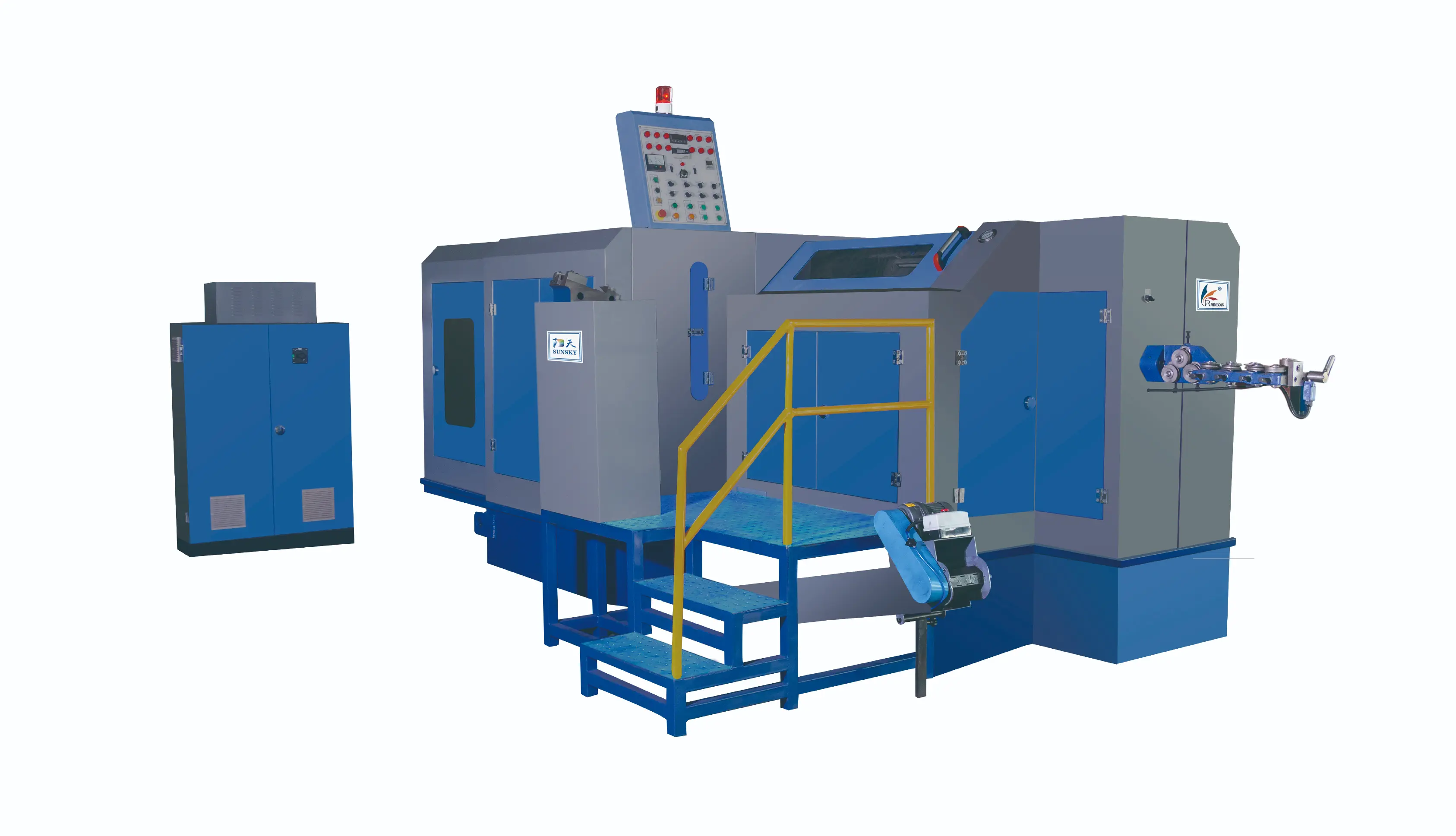

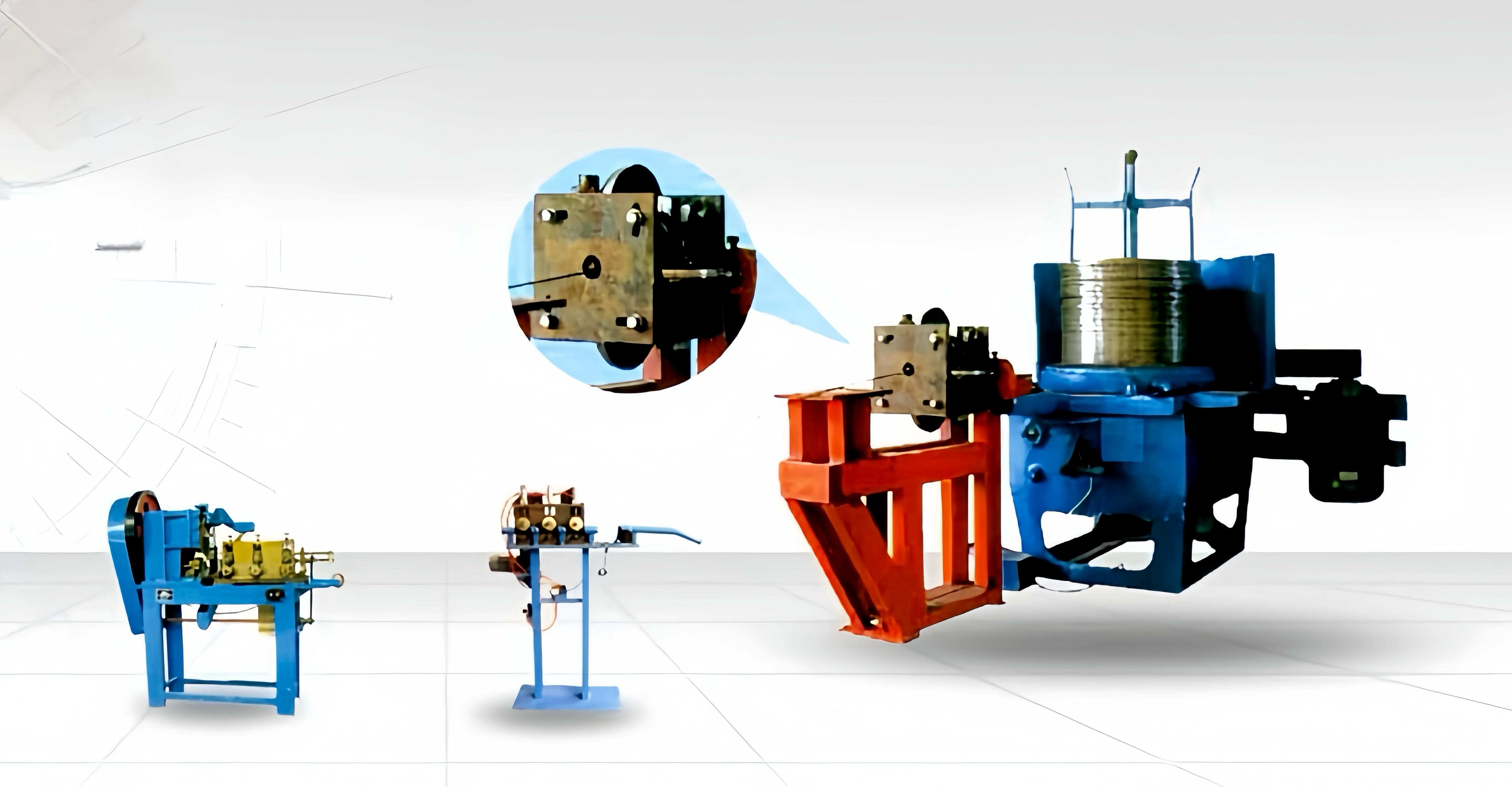

Engineered for Industrial Excellence

FastenersMachine.com specializes in the design and manufacturing of high-performance industrial machinery for the fastener and metal forming industry. Our machines are built for durability, precision, and unmatched production efficiency.

From spring washer making machines to multi-station bolt formers and copper wire drawing systems, our equipment serves manufacturers across automotive, construction, aerospace, and industrial sectors.

- High-speed cold forming technology

- CNC-controlled precision engineering

- Energy-efficient and low maintenance

- Global compliance and safety standards