About Favamill

Shenzhen Favamill Testing Equipment Co., Ltd. is located next to Shenzhen International Airport, with convenient transportation. It is a production-oriented enterprise engaged in automotive inspection tools, tooling fixtures, and welding fixtures. With over 25 years of experience, we are a trusted partner for global automotive manufacturers.

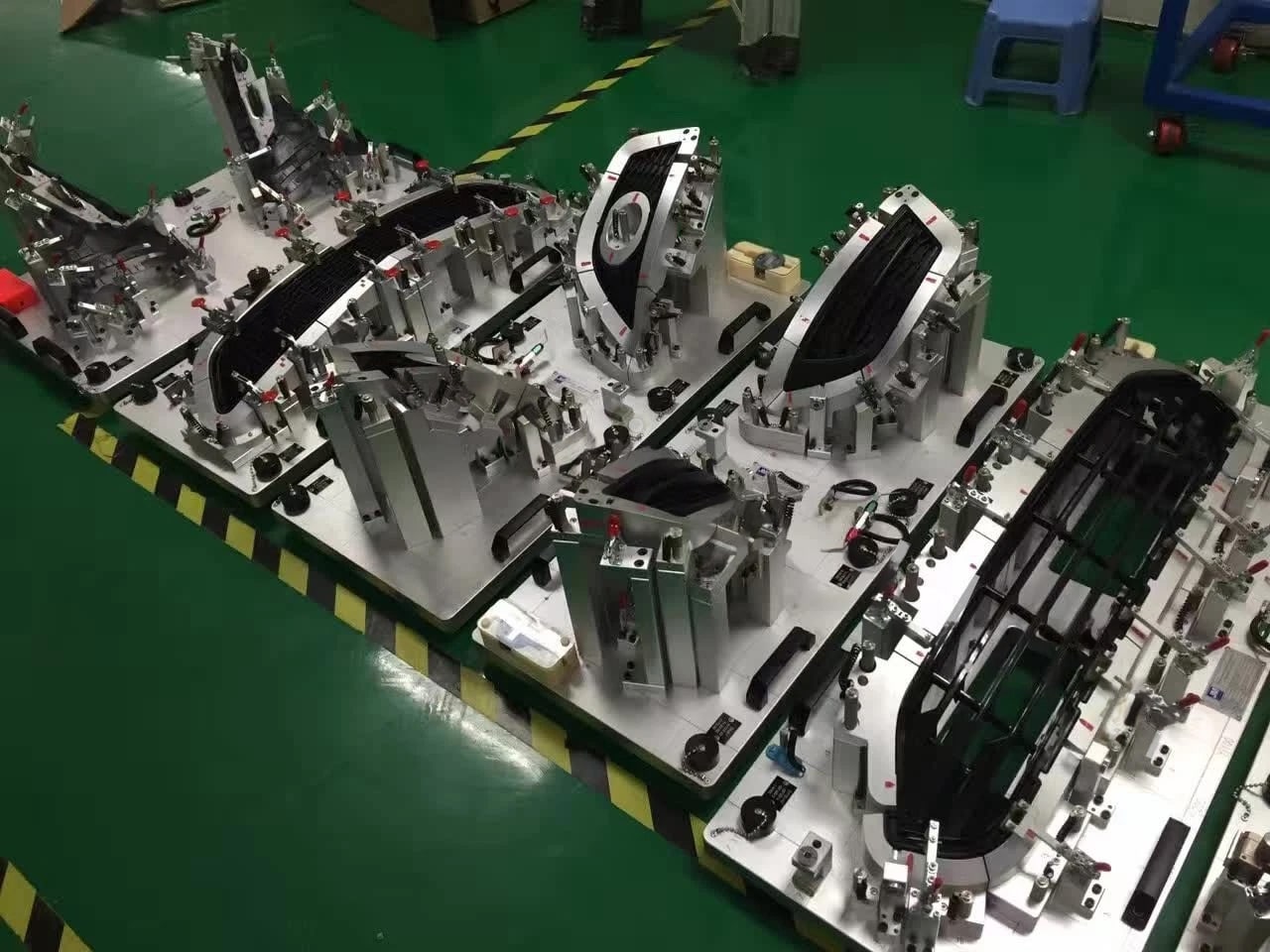

We specialize in the design and manufacturing of precision checking fixtures, CMM holding fixtures, jigs & gauges, and custom welding solutions. Our team combines deep industry knowledge with advanced engineering to deliver reliable, high-precision tools that enhance production efficiency and quality control.

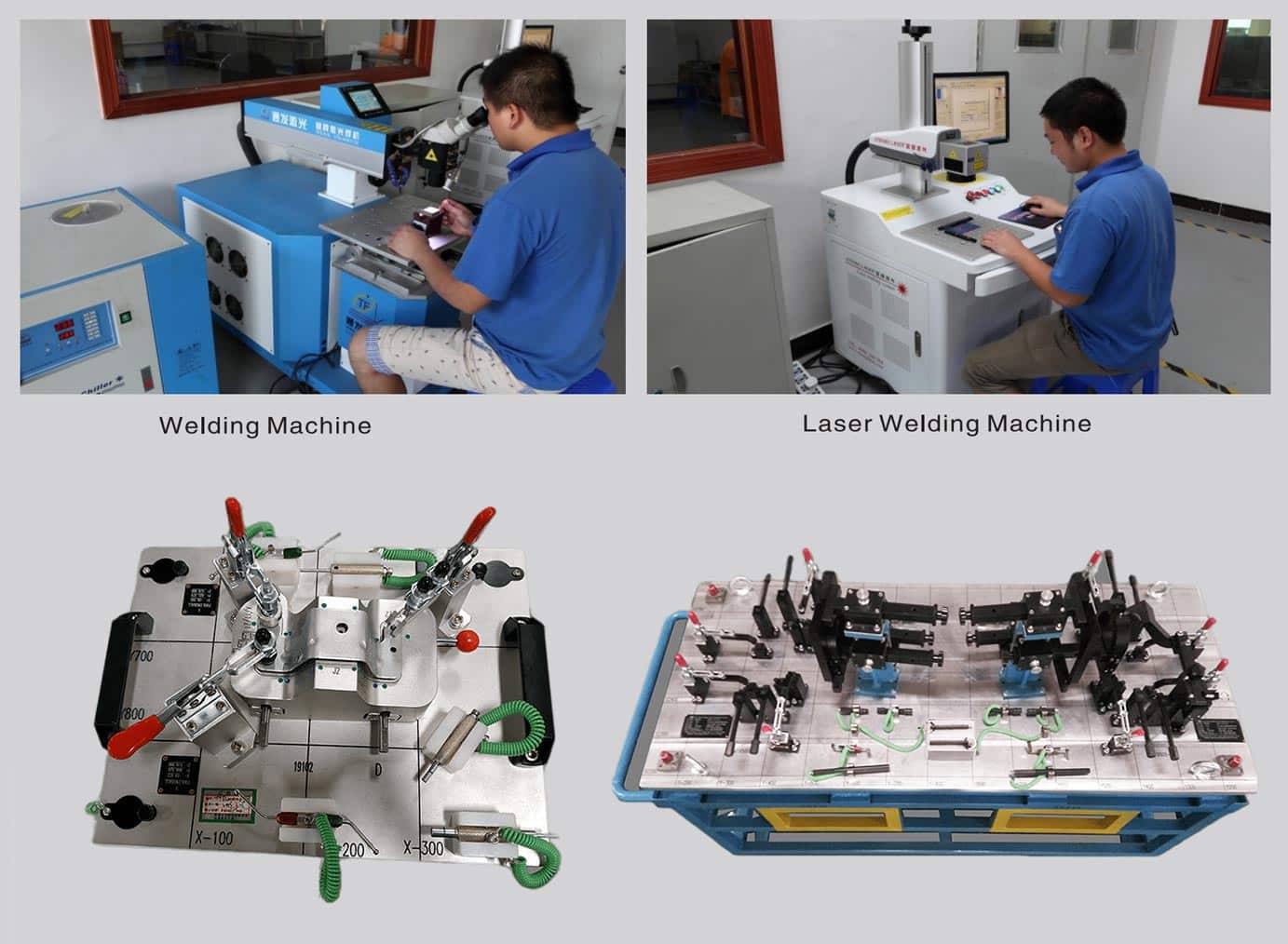

Strong Manufacturing

Rich industry experience and strong production capability.

Craftsmanship Design

Tailored fixture design based on specific customer needs.

Quality Assurance

ISO9001 standard with three-layer quality inspection.

Good Service

24-hour response and accurate delivery timelines.