About FD Machinery

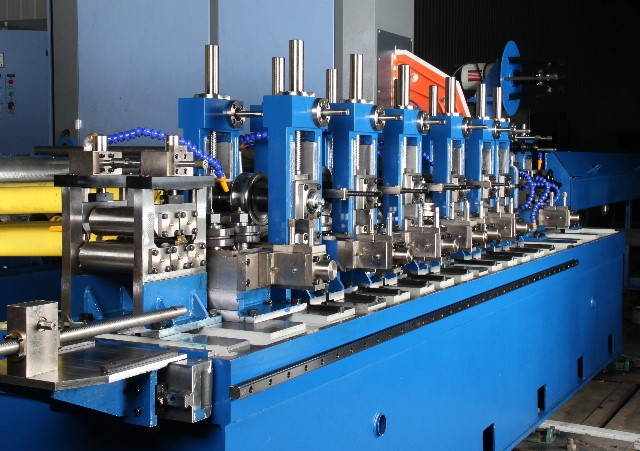

At FD Machinery, we are committed to producing the highest quality, cost-effective solutions for your tube and pipe manufacturing needs. With over 27 years of experience and equipment installations across the globe, we’ve earned our reputation as the true experts in the field.

Our innovative thinking has led to 50 patents, keeping both us and our clients at the forefront of technology. We employ multiple weld technologies — HF, Laser, TIG, and Plasma — to serve a wide range of industries including construction, automotive, and energy.

- 27+ years of industry leadership

- 50+ patented technologies

- Global installations and support

- Precision engineering for long equipment life