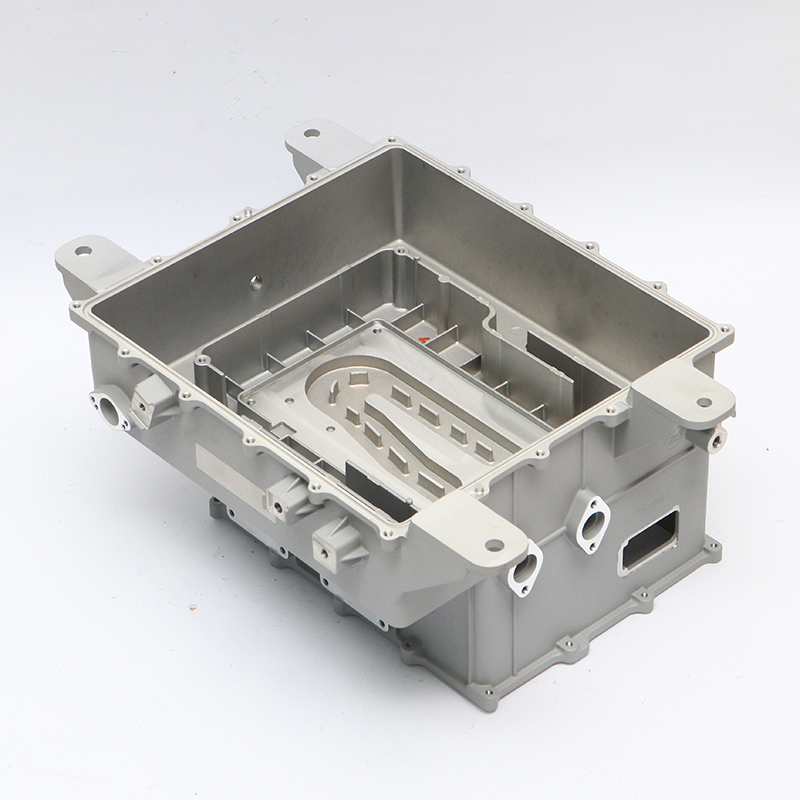

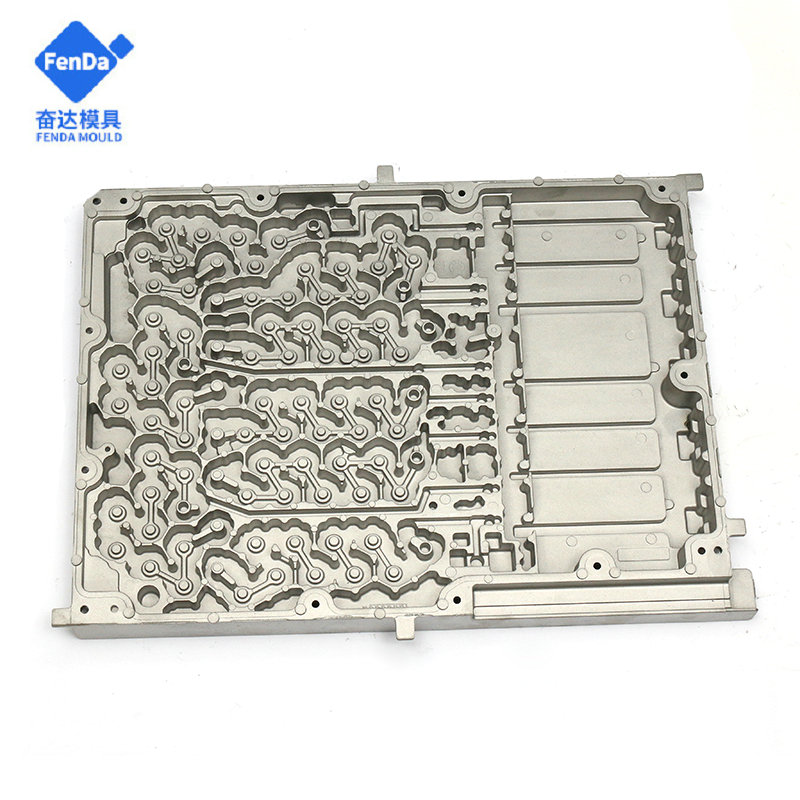

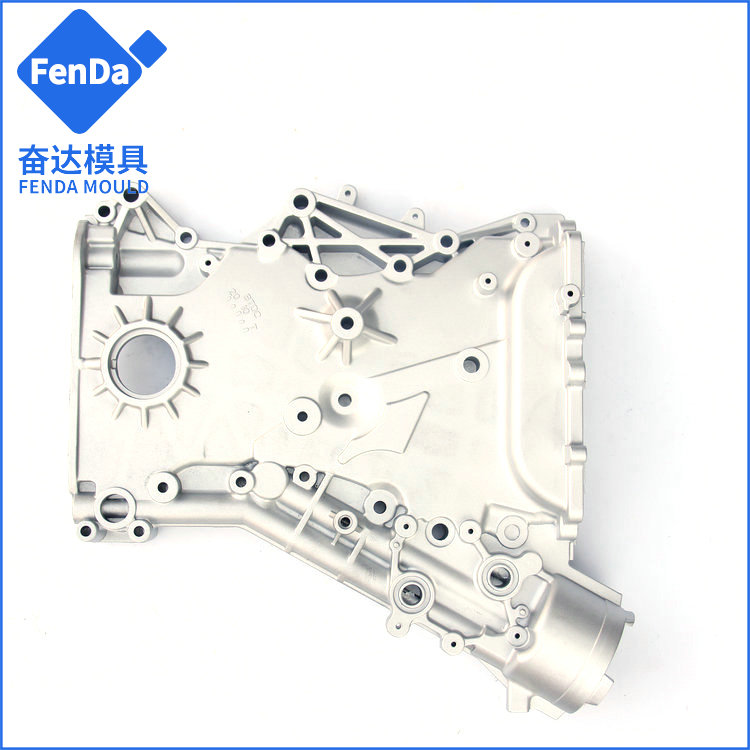

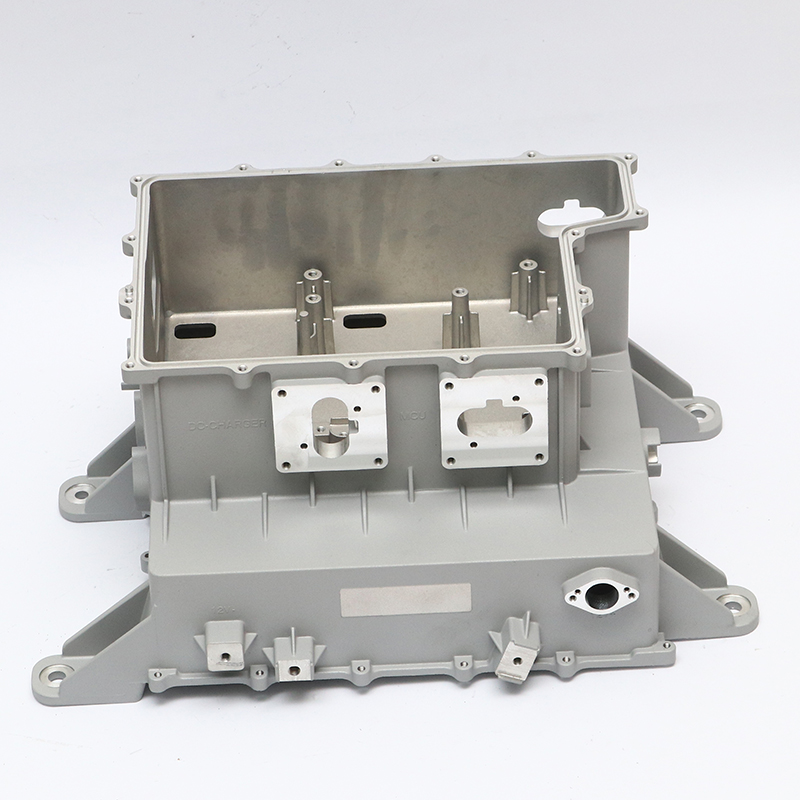

Precision Die Casting Solutions for Automotive, EV & Industrial Applications

Fenda Die Casting is a trusted OEM/ODM manufacturer specializing in aluminum and zinc die casting, CNC machining, and surface treatment. With over 18 years of experience, we deliver high-quality, custom-engineered components for automotive, electric vehicles, LED lighting, telecom, and power tools.