Company Introduction

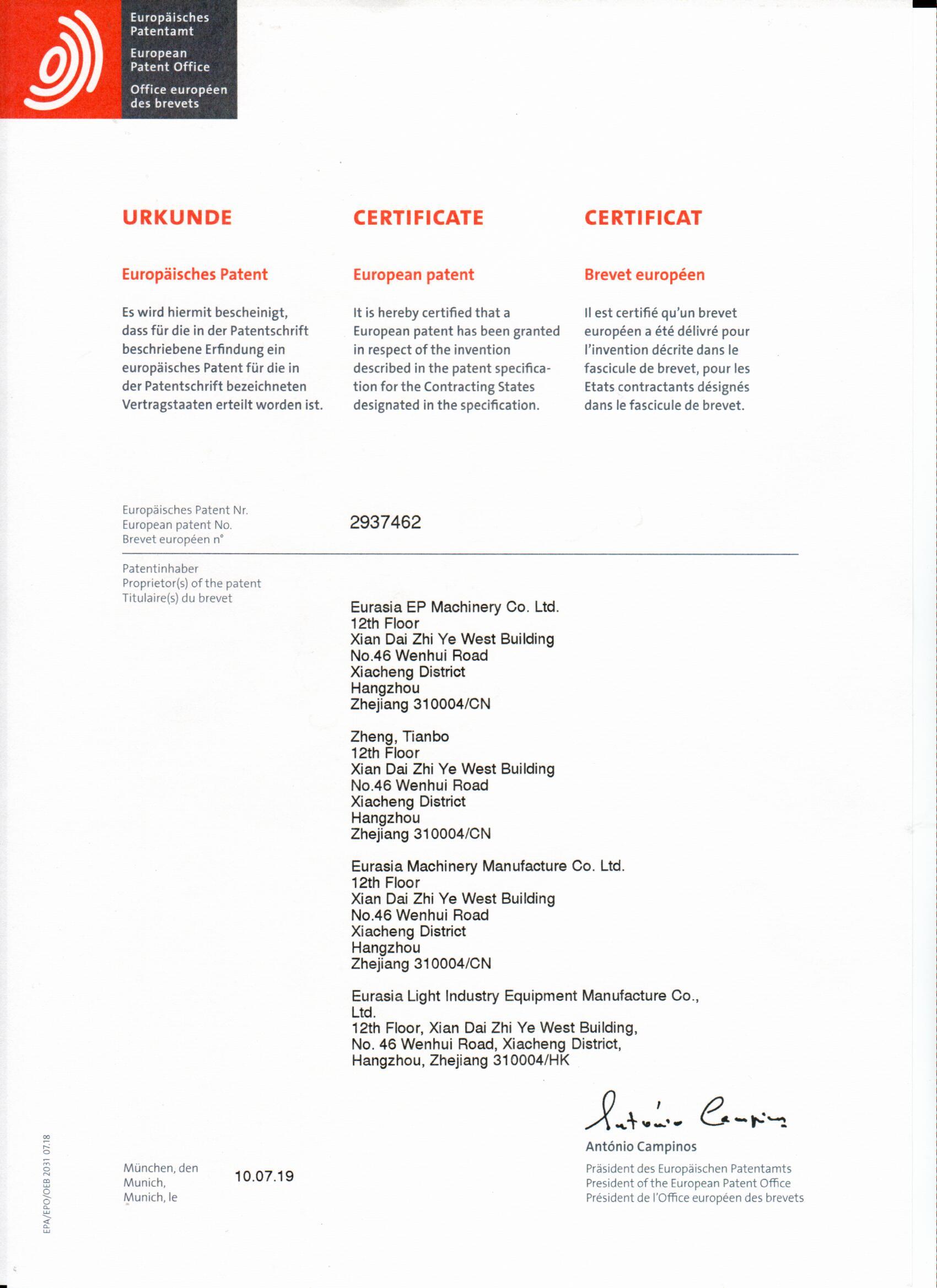

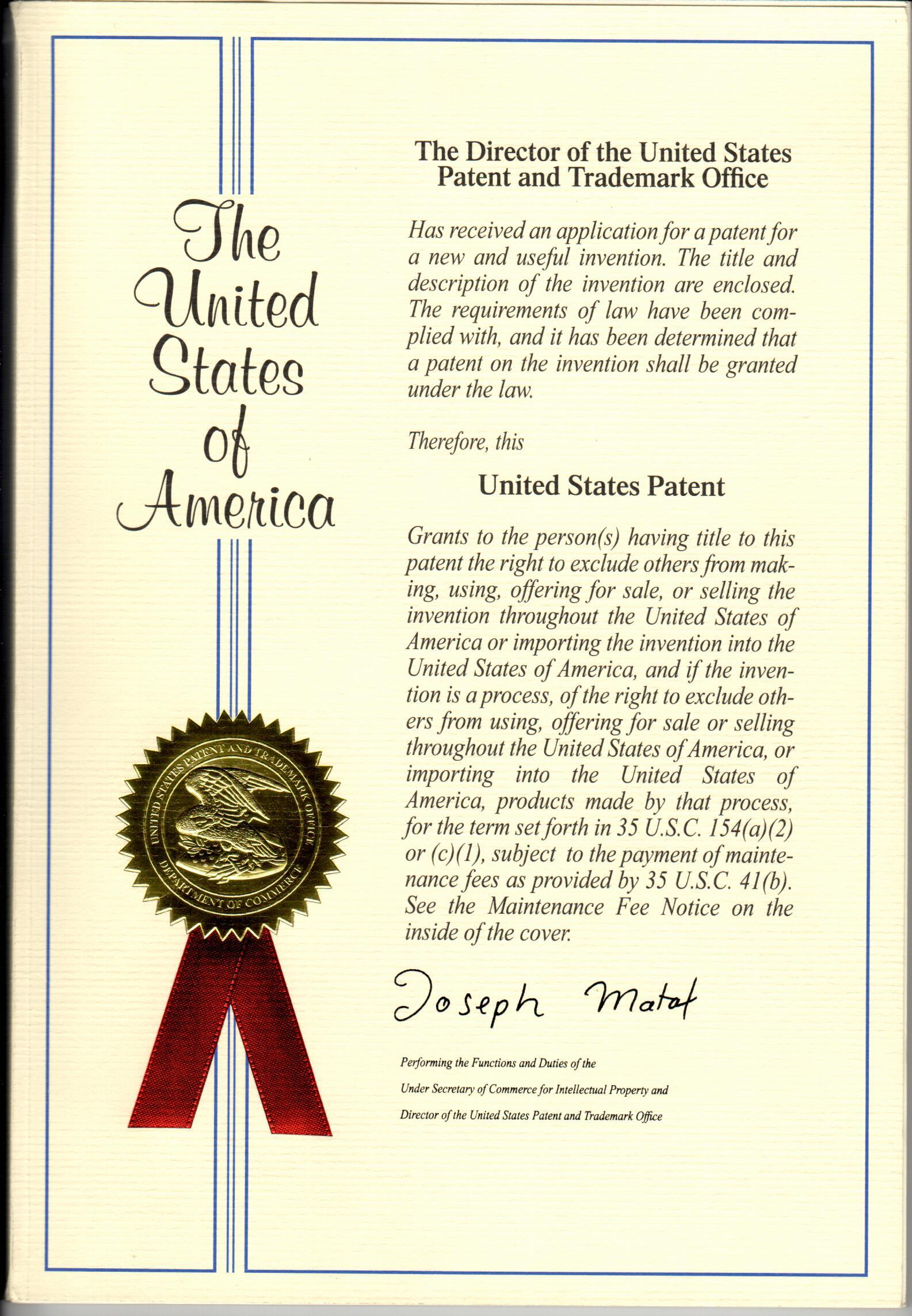

EAMC is the pioneer of international fully automatic pulp molding production technology and the inventor of the "forming, drying and trimming machine". The entire machine and key components hold a series of Chinese, American, and European Union invention patents.

EAMC established China's first academician workstation for plant fiber molding and is the first drafter of Chinese Industry Standards including “Pulp Molding Disposable Tableware Production Line” and “Pulp Molding Machine for Fine Packaging Products”.

Chairman and Chief Engineer Zheng Tianbo, a Professorate Senior Engineer, has been researching pulp (plant fiber) molding technology since 1992. He is a member of the Technical Committee of the National Standard Committee of China and a Technical Justice Expert of Zhejiang and Jiangsu Province.

View Our Technology