Precision Mold Manufacturing

Since 2000

China-based contract manufacturer specializing in plastic, silicone, and metal molds with full turnkey production services. ISO9001, TS16949, and ISO13485 certified.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

China-based contract manufacturer specializing in plastic, silicone, and metal molds with full turnkey production services. ISO9001, TS16949, and ISO13485 certified.

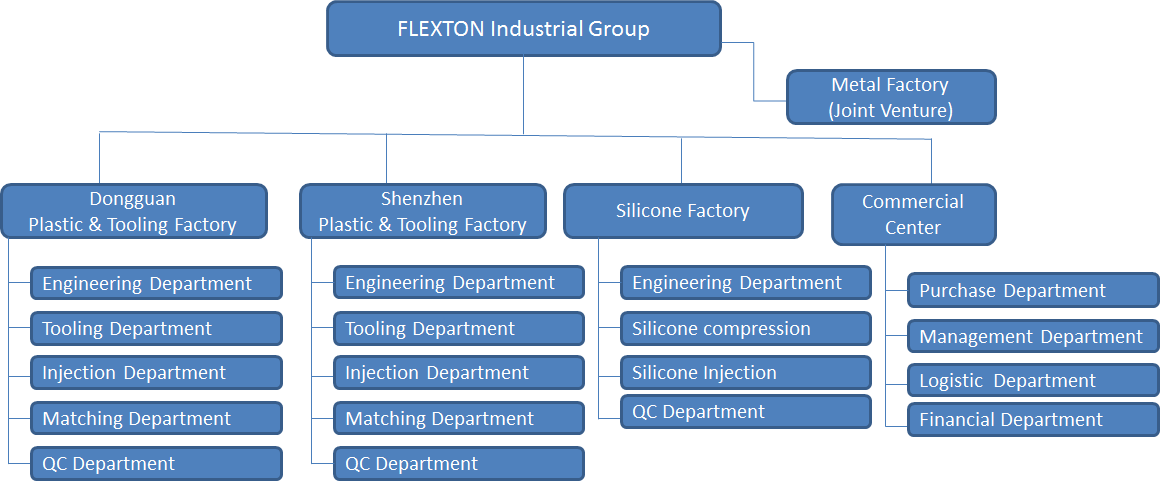

Flexton Mold was established in 2000 as one of the most competitive and comprehensive contract manufacturers in China. We specialize in producing high-precision plastic, silicone, and metal molds along with their finished parts.

With two advanced facilities located in Shenzhen and Dongguan, and a joint-venture metal factory, we deliver end-to-end manufacturing solutions. Our professional team ensures seamless sourcing of standard components, enabling a true one-stop turnkey service for global clients.

Over two decades of precision engineering excellence.

Shenzhen & Dongguan production centers.

We work closely with clients to finalize designs, evaluate drawings, and deliver optimal manufacturing solutions for efficient mass production.

Quick-turn prototypes using real production materials and finishes to validate assembly, aesthetics, and functionality early in development.

Full-scale production of plastic, silicone, and metal molds and their finished parts with strict process control and scalability.

In-house secondary operations including ultrasonic welding, silk & pad printing, laser engraving, painting, electroplating, packaging, and assembly.

High-precision molds for automotive, consumer electronics, and medical applications. Multi-cavity and hot runner systems available.

Medical-grade and food-safe silicone molds for healthcare devices, kitchenware, and consumer products.

Progressive and transfer dies for precision metal components in automotive and industrial sectors.

Interior and exterior components including dashboards, connectors, and housings.

ISO13485-compliant molds for surgical tools, diagnostic equipment, and disposable devices.

Precision enclosures for IoT devices, sensors, and smart home products with EMI shielding options.

Durable plastic and metal connectors for machinery, automation, and power systems.

Molds for food containers, utensils, and small appliances with non-stick and easy-clean surfaces.

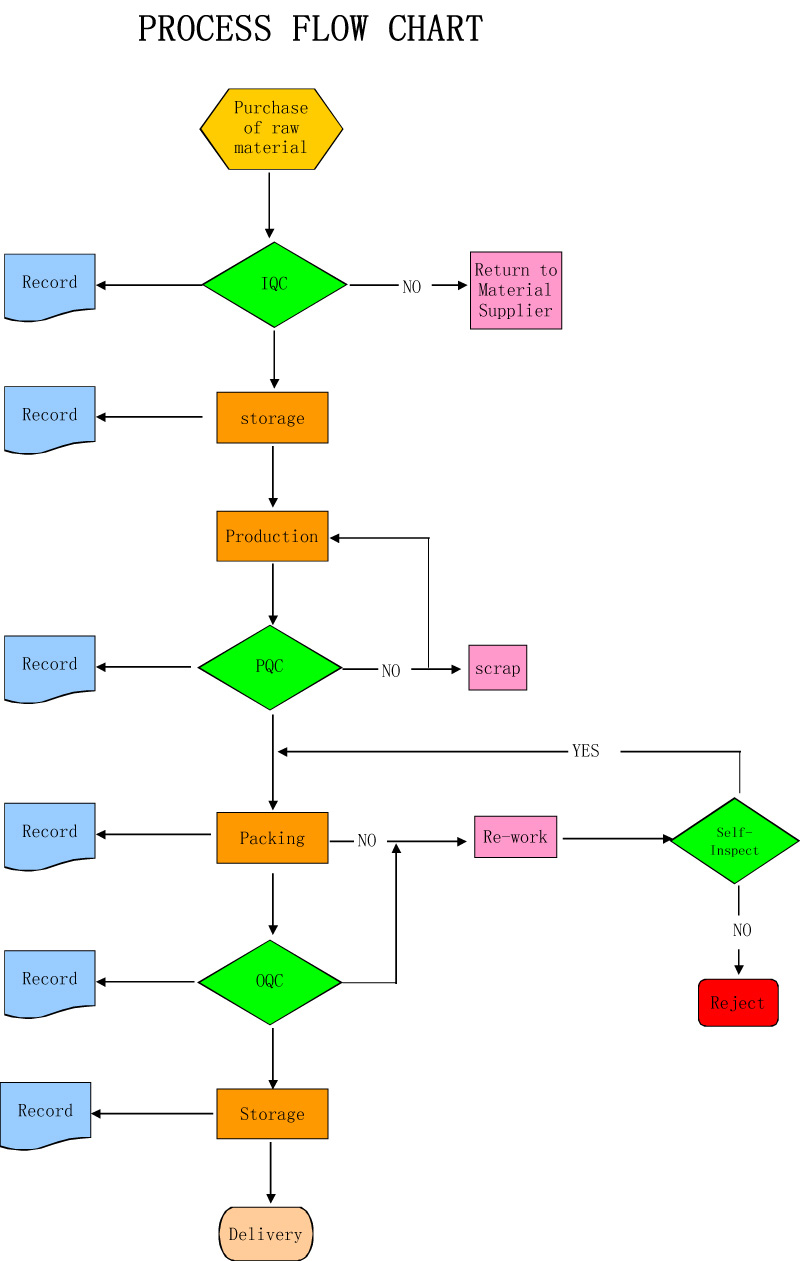

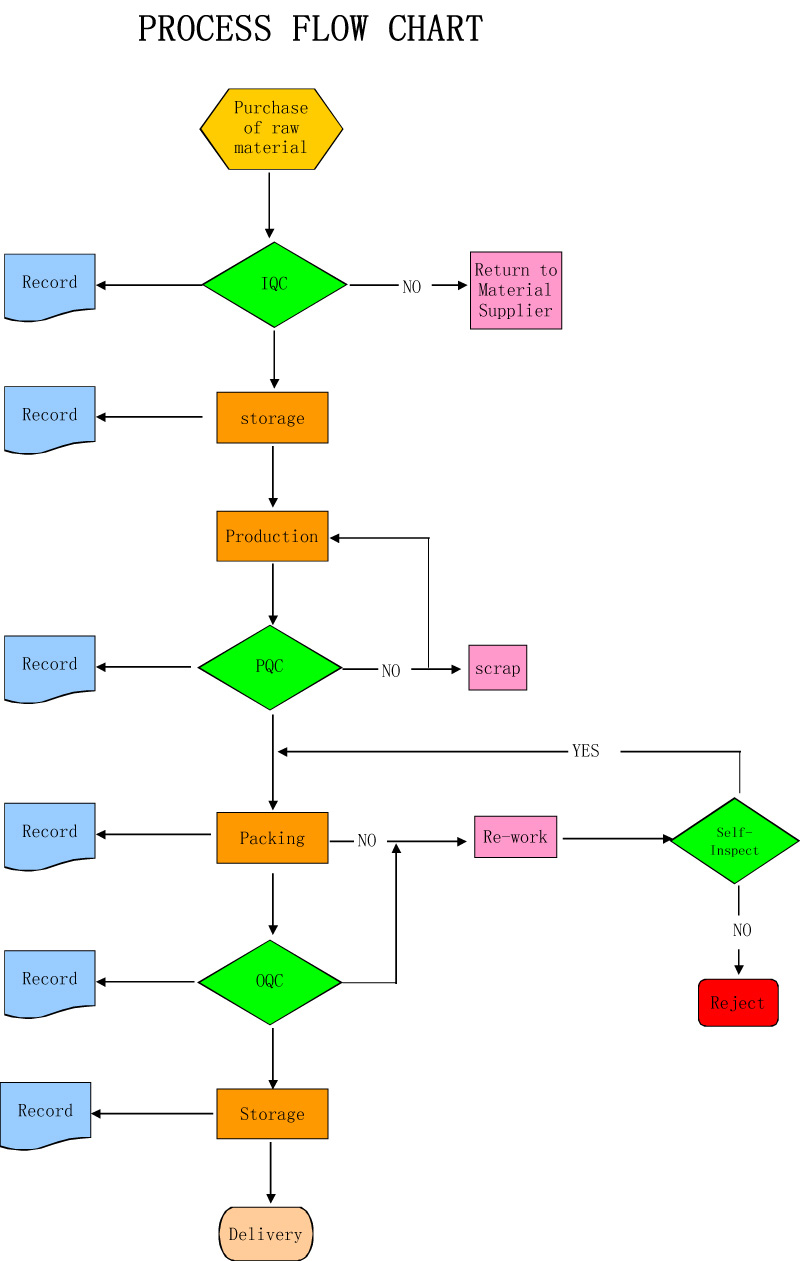

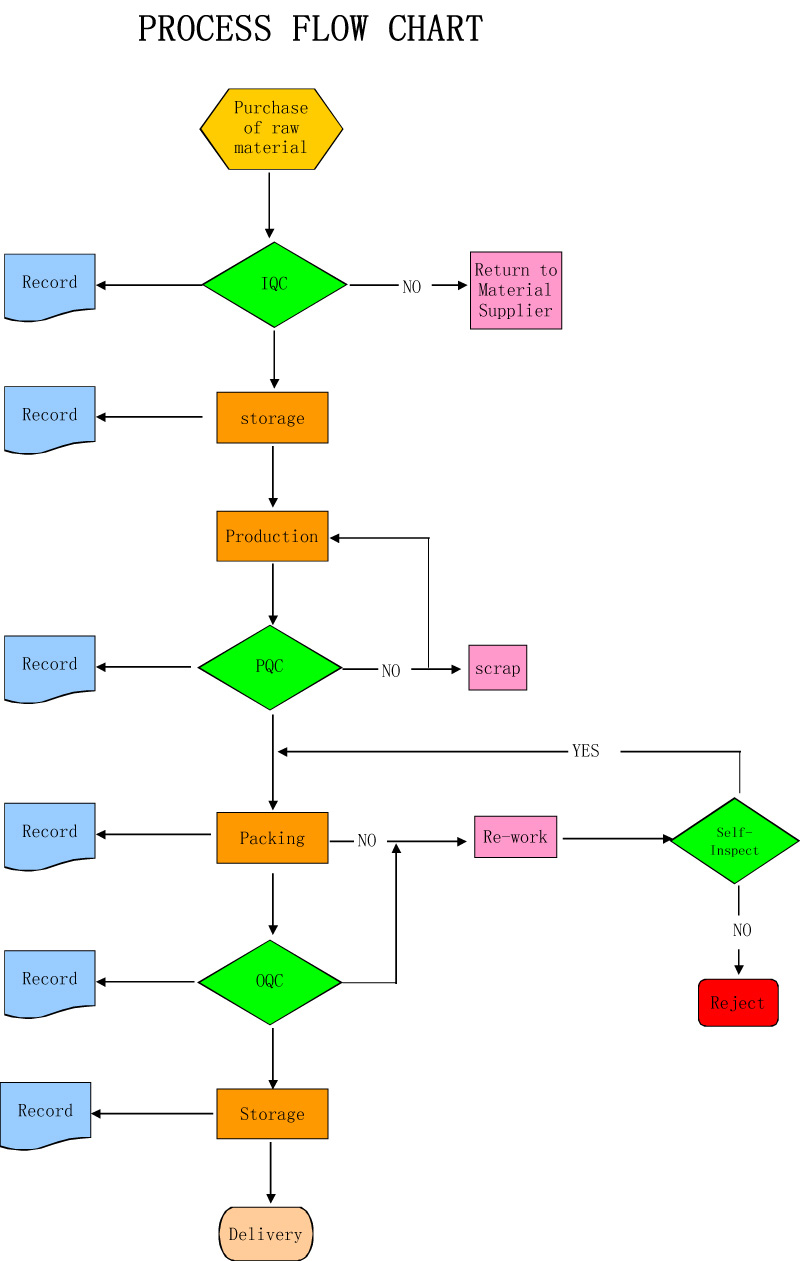

At Flexton Tec, quality is embedded in every stage of production. We adhere to international standards and implement rigorous inspection protocols to ensure consistency and reliability.

Comprehensive quality management systems for consistent output and continuous improvement.

Automotive-specific QMS ensuring reliability and traceability for critical components.

Medical device quality standards for safe and effective healthcare products.

We specialize in a wide range of materials including ABS, PC, PP, PA, POM for plastics; medical and food-grade silicone; and various metals such as steel, aluminum, and brass for stamping and die-casting.

Yes, we are certified under ISO9001, TS16949, and ISO13485, ensuring compliance with international quality standards across automotive, medical, and general manufacturing sectors.

Our primary facilities are located in Shenzhen and Dongguan, China. We also operate a joint-venture metal factory to support integrated production needs.

Yes, we provide rapid prototyping using real production materials and finishes to validate design, assembly, and aesthetics before full-scale production.

We offer in-house services including ultrasonic welding, silk and pad printing, laser engraving, oil painting, electroplating, packaging, and full assembly.

Ready to start your next project? Contact Flexton Tec for expert mold design, manufacturing, and turnkey solutions.

Visit Official WebsiteNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info