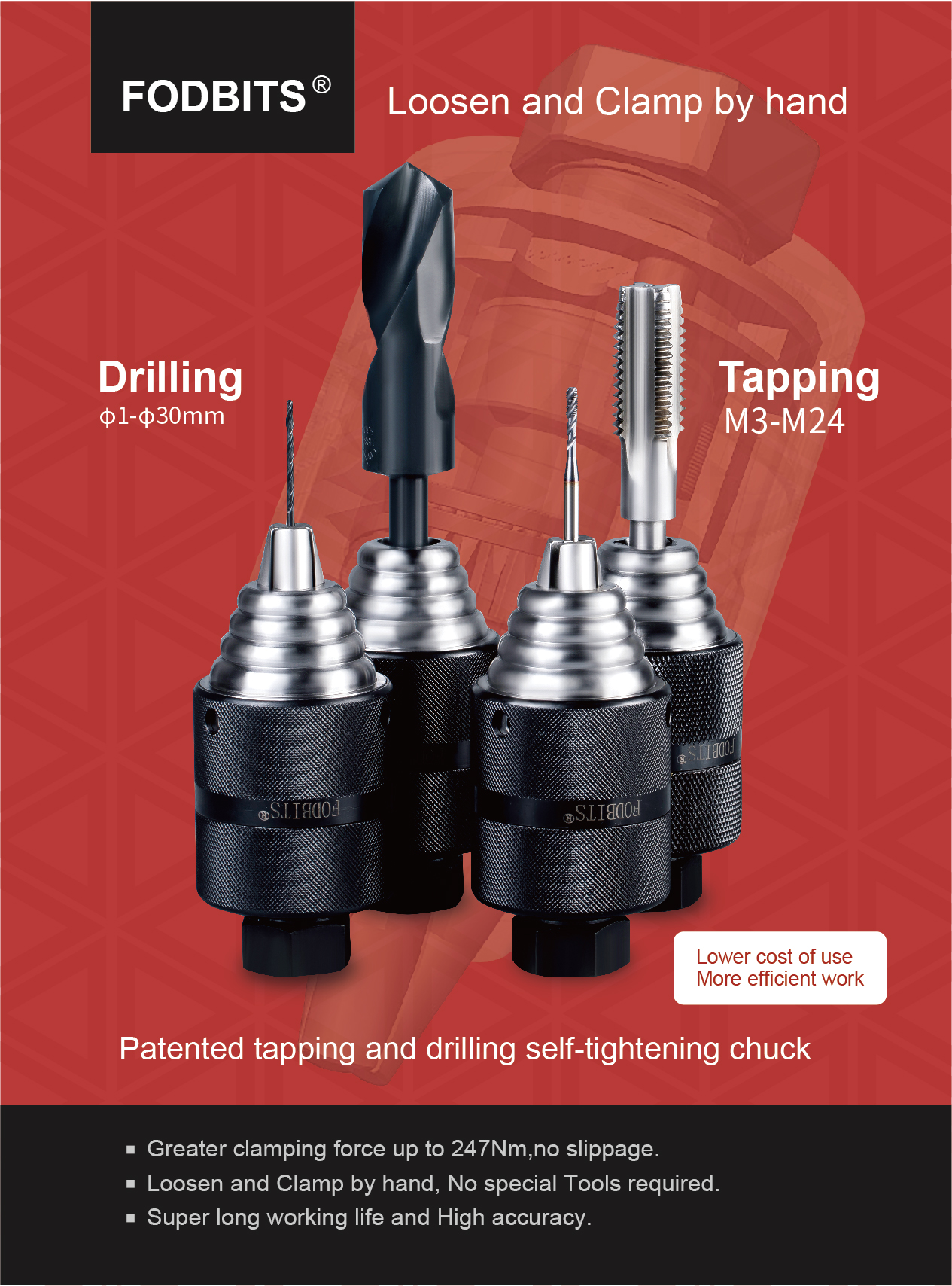

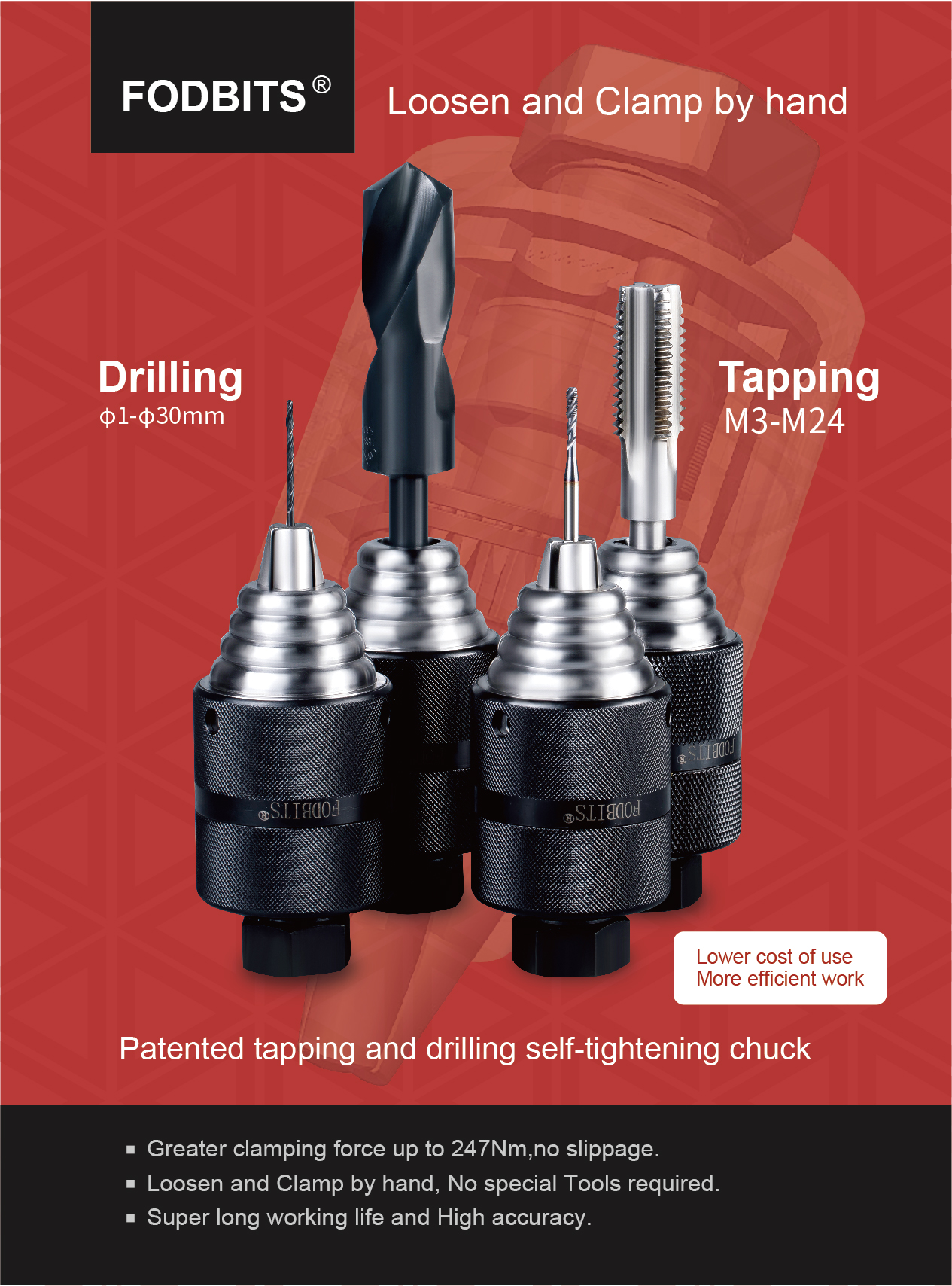

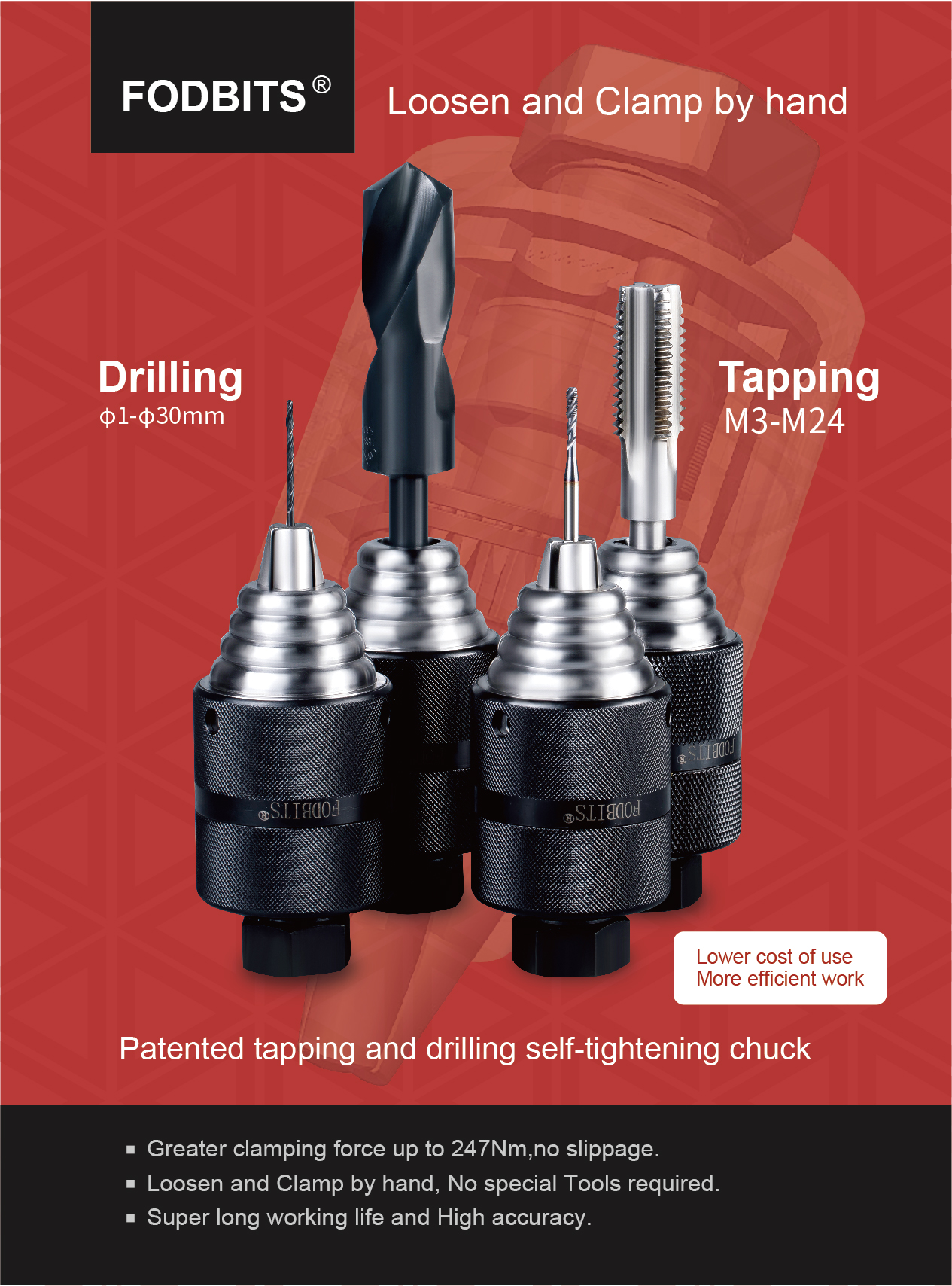

FODBITS® Self-Tightening Chucks

Engineered with three international patents, our high-precision chucks eliminate slippage, reduce setup time, and deliver unmatched performance in drilling and tapping applications.

Explore ProductsThis page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Engineered with three international patents, our high-precision chucks eliminate slippage, reduce setup time, and deliver unmatched performance in drilling and tapping applications.

Explore ProductsFodbits Precision Technology Co., Ltd. was founded by Mr. Lambert Leou in Canada in 2021. Building on over 12 years of R&D experience from Weihai Dawang Machinery Technology Co., Ltd. in China, our mission is to revolutionize the drill chuck industry.

Since July 2010, our team has focused on solving five major pain points that have plagued the drill chuck market for over 125 years. The result? The FODBITS® multifunctional self-tightening chuck — a patented innovation that delivers automatic tightening, no slippage, and effortless manual release.

Engineered for performance, reliability, and ease of use.

Automatic tightening under load ensures zero slippage during operation.

No hook spanner needed — release by hand after tapping or drilling.

Capable of tapping M24 threads and drilling Φ30mm holes.

Reverse rotation and locking with a single operation.

Precision-engineered chucks for CNC, milling, drilling, and tapping machines.

The FODBITS® chuck uses a gear transmission system that automatically tightens the drill bit as cutting resistance increases, eliminating slippage during operation.

Yes, our chucks are designed for both drilling and tapping operations, with consistent torque in forward and reverse rotation.

No. The chuck can be loosened by hand after operation — no hook spanner required.

Yes, many models are designed for CNC machining centers, including compatibility with BT, CAT, DAT, and MAS403 tool holders.

For inquiries about our products or pricing, please visit our official website.

Visit Official WebsitePhone/WhatsApp: 001 604 782 2677

Email: info@fodbits.com, fodbits@gmail.com

Address: 10640 Argentia Dr, Richmond BC V7E4K5 Canada

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info