Premium Industrial Ceramics for Demanding Applications

XIAPU FUHONG CERAMIC CO., LTD – Trusted manufacturer of mullite, alumina, steatite, and zirconia ceramics with over 20 years of expertise in high-performance ceramic components.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

XIAPU FUHONG CERAMIC CO., LTD – Trusted manufacturer of mullite, alumina, steatite, and zirconia ceramics with over 20 years of expertise in high-performance ceramic components.

Located in Xiapu County, Fujian Province, China, XIAPU FUHONG CERAMIC CO., LTD specializes in manufacturing and selling high-quality industrial ceramics including mullite ceramic, 95% alumina ceramic, steatite ceramic, and zirconia ceramic.

We produce insulating parts for wirewound resistors, fuses, ceramic honeycombs for RTO and RCO technologies, ceramic rods, and custom-engineered ceramic components for diverse industrial applications.

High-performance ceramic components engineered for reliability, thermal stability, and electrical insulation in demanding industrial environments.

High-temperature resistant insulating tube for fuses and resistors.

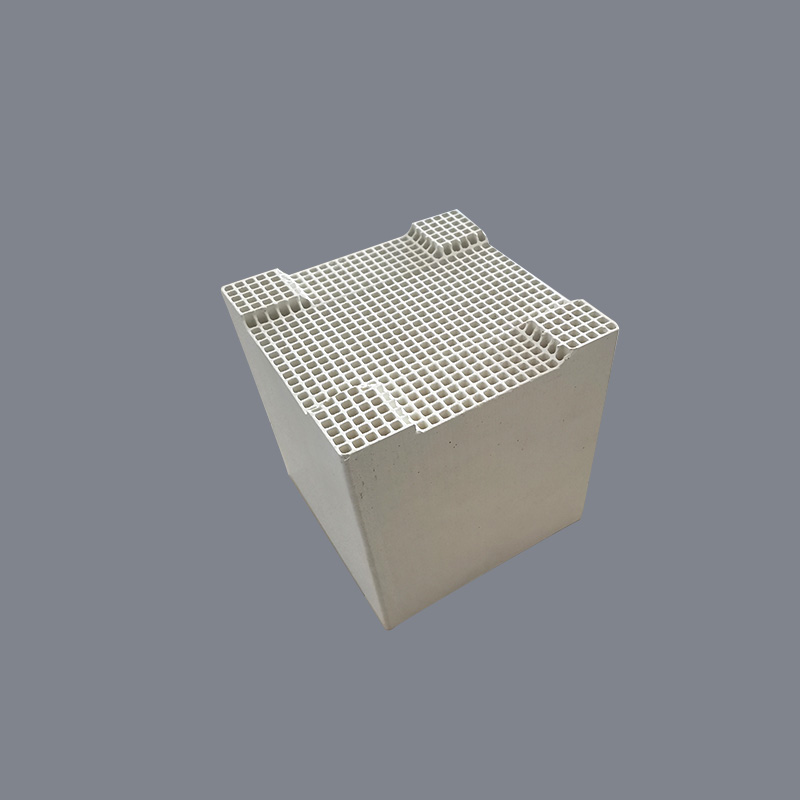

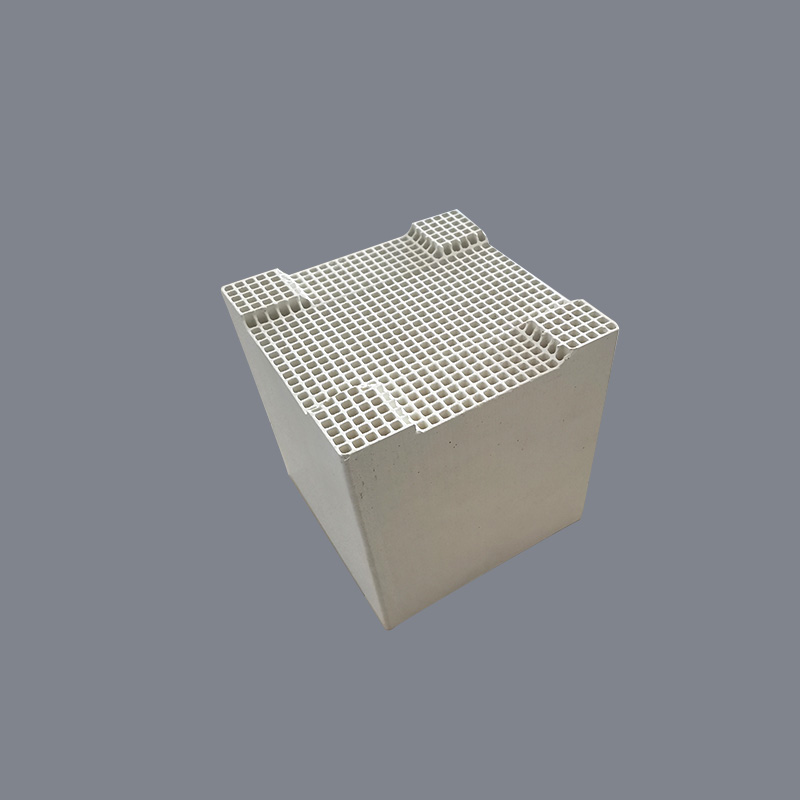

Mullite ceramic honeycomb structure for RTO and RCO systems.

High-purity alumina components for electrical insulation and wear resistance.

Precision-engineered rods for mechanical and electrical applications.

Designed for wirewound resistors and high-voltage insulation.

Optimized for heat retention and gas flow in industrial burners.

Low-cost, high-insulation ceramic for electrical and electronic applications.

High-toughness ceramic for extreme mechanical and thermal conditions.

Tailored ceramic components based on client specifications and drawings.

Reliable electrical insulation for high-voltage and high-temperature systems.

Our mullite and alumina ceramic tubes provide excellent arc quenching, thermal shock resistance, and mechanical strength in high-current fuse applications.

Used as insulating substrates in wirewound resistors, our ceramics ensure stable electrical performance under high power and elevated temperatures.

Expert guidance and technical consultation for ceramic material selection and application engineering.

Our engineering team provides comprehensive support including material recommendations, thermal and mechanical analysis, prototyping, and failure analysis.

Whether you're designing a new component or replacing an existing one, we help you choose the optimal ceramic material and geometry.

Request Technical SupportWe specialize in mullite ceramic, 95% alumina ceramic, steatite ceramic, zirconia ceramic, and custom ceramic composites.

Yes, we offer full customization based on your drawings, samples, or specifications. Prototyping is available.

Standard products: 2–4 weeks. Custom orders: 4–8 weeks depending on complexity.

Yes, we provide material test reports and quality certificates upon request.

We export globally, with strong presence in Europe, North America, Southeast Asia, and the Middle East.

Contact us for product inquiries, technical support, or custom solutions.

info@fromceramic.com

Primary contact

+86-15867721883

Mobile / WhatsApp

+86-593-8875598

Fujian, China

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info