High Performance

Crack-free Fused Alloy Wear Plates

Eliminate material hangup • Increase material flow • Extend service life • Boost productivity

Learn MoreThis page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Eliminate material hangup • Increase material flow • Extend service life • Boost productivity

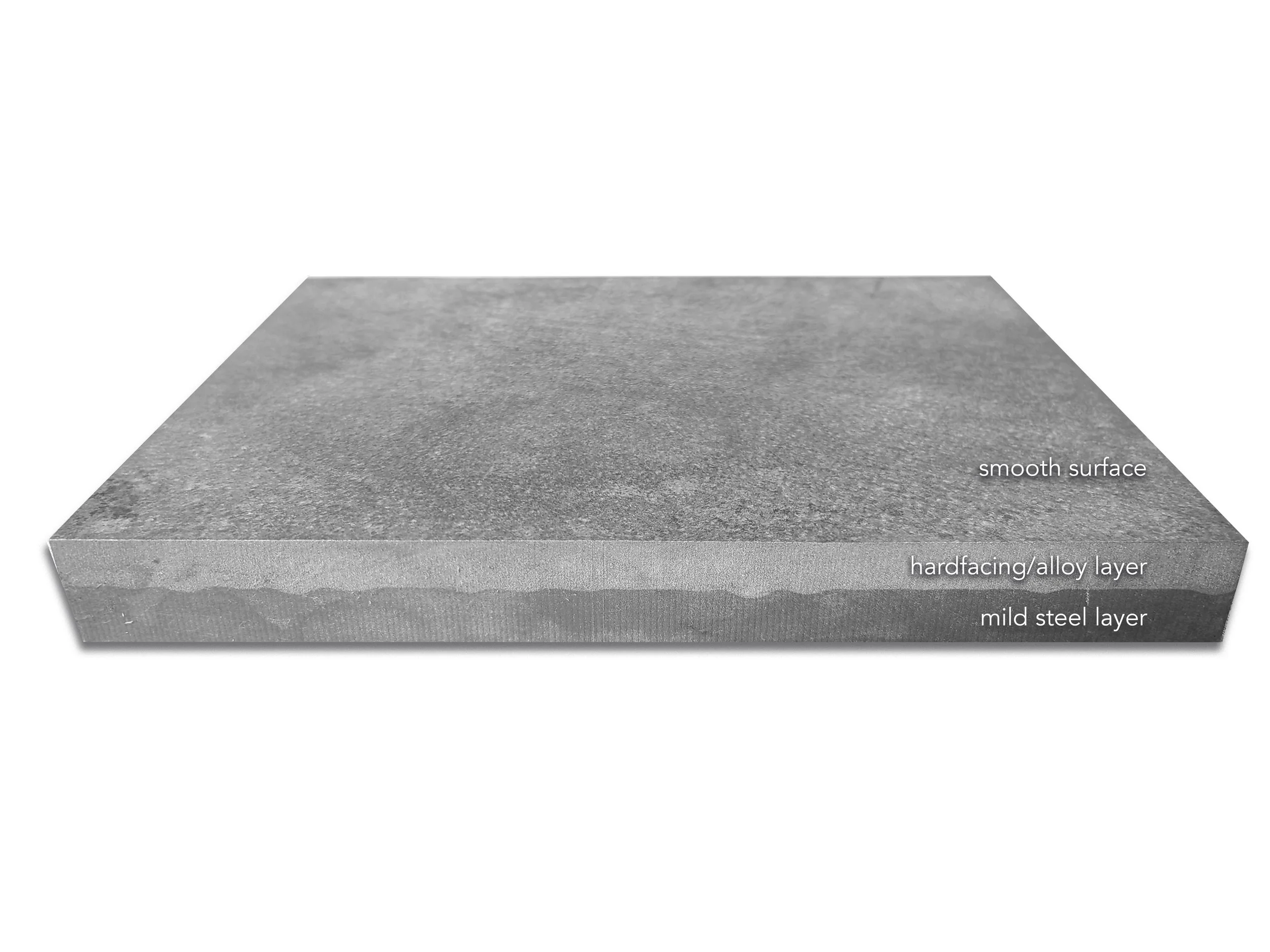

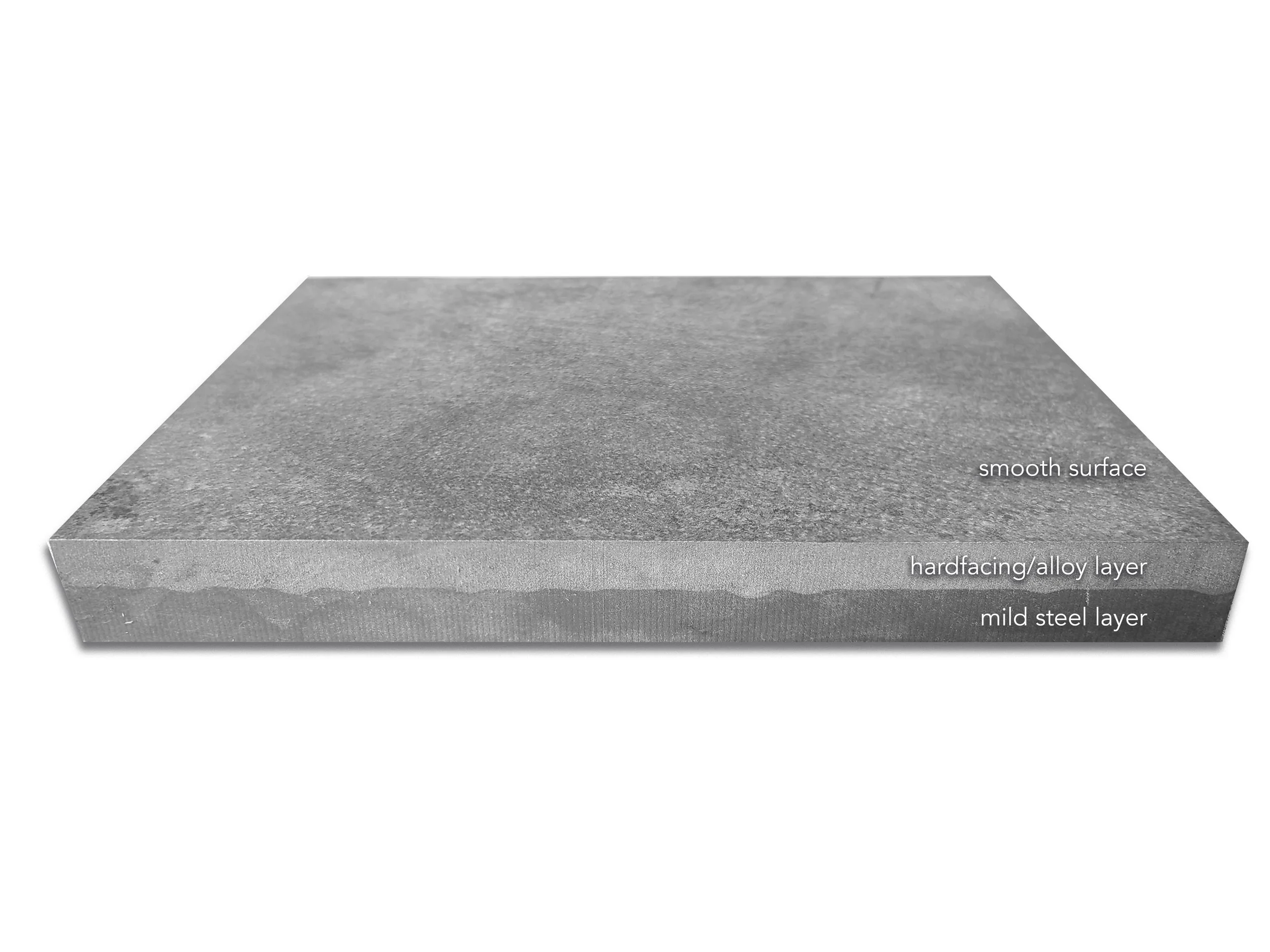

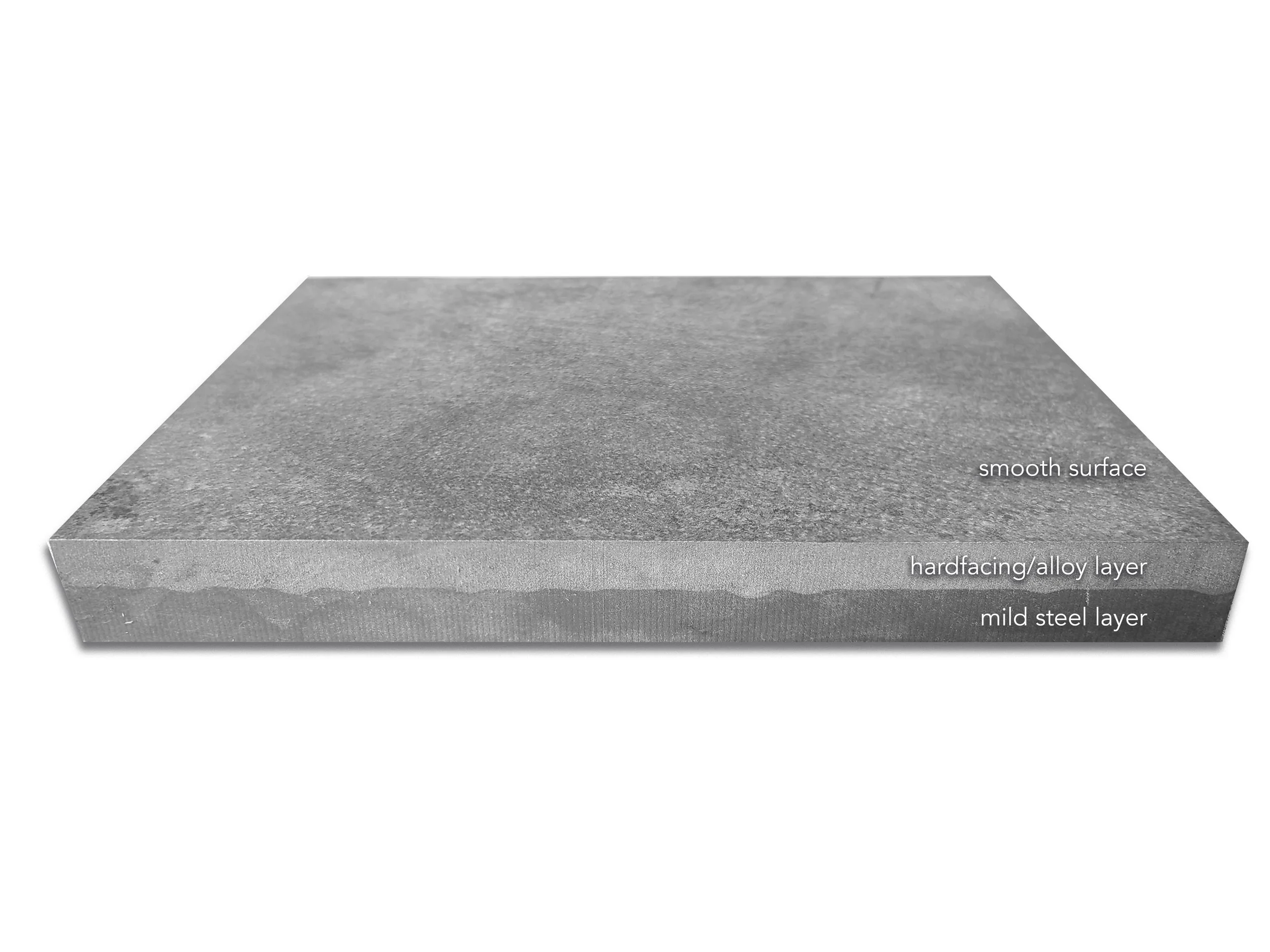

Learn MoreFT plates consist of a mild steel base combined with a fully smooth, wear-resistant coating, presenting a steel overlay sheet of superior quality.

Deriving from Japan, our fusing technology has evolved after years of continuous research and innovation to enable a product that achieves excellent wear and impact performance.

Access Product Data

Our smooth surface CCO plates are highly versatile and can be customized to meet your unique project needs. They can be precisely cut, rolled, bent, and shaped according to your specific requirements.

19+

Countries

4

Mining, Waste, Coal, Quarry

3-5x

Longer than standard plates

Smooth to the touch, tough to the core

For high abrasion and moderate impact applications.

For high abrasion and high impact applications.

Proprietary fusing technique from Japan for superior bonding.

Precision-cut wear plates for seamless integration.

Superior anti-hangup for sticky and humid environments.

Ready-fit components with studs, bolts, and brackets.

Fine and hard chrome carbide evenly dispersed in alloy matrix.

Prevent hang-up and extend liner life in transfer points.

Engineered for performance and reliability

Smooth surface prevents material buildup and blockages.

Promotes consistent material movement and throughput.

3-5x longer service life compared to standard wear plates.

Less downtime and safer maintenance cycles.

Industry: Mining

Wear Factor: Sliding abrasion & impact

Material: M30

Industry: Cement

Wear Factor: Sliding abrasion

Material: M30

Industry: Coal Mining

Wear Factor: Sliding abrasion & impact

Material: M70

Industry: Coal Mining

Wear Factor: Sliding abrasion & impact

Material: M70

Have questions or need more information about our smooth CCO plates? We're here to help!

info@futong-welding.com

info@fusetech.au

+61 4 81709997 (English)

+86 13806119132 (Mandarin)

Level 8, 220 Collins St, Melbourne, VIC, 3000, Australia

No.28, Shunyuan Rd, ChangZhou, Jiangsu, 213002

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info