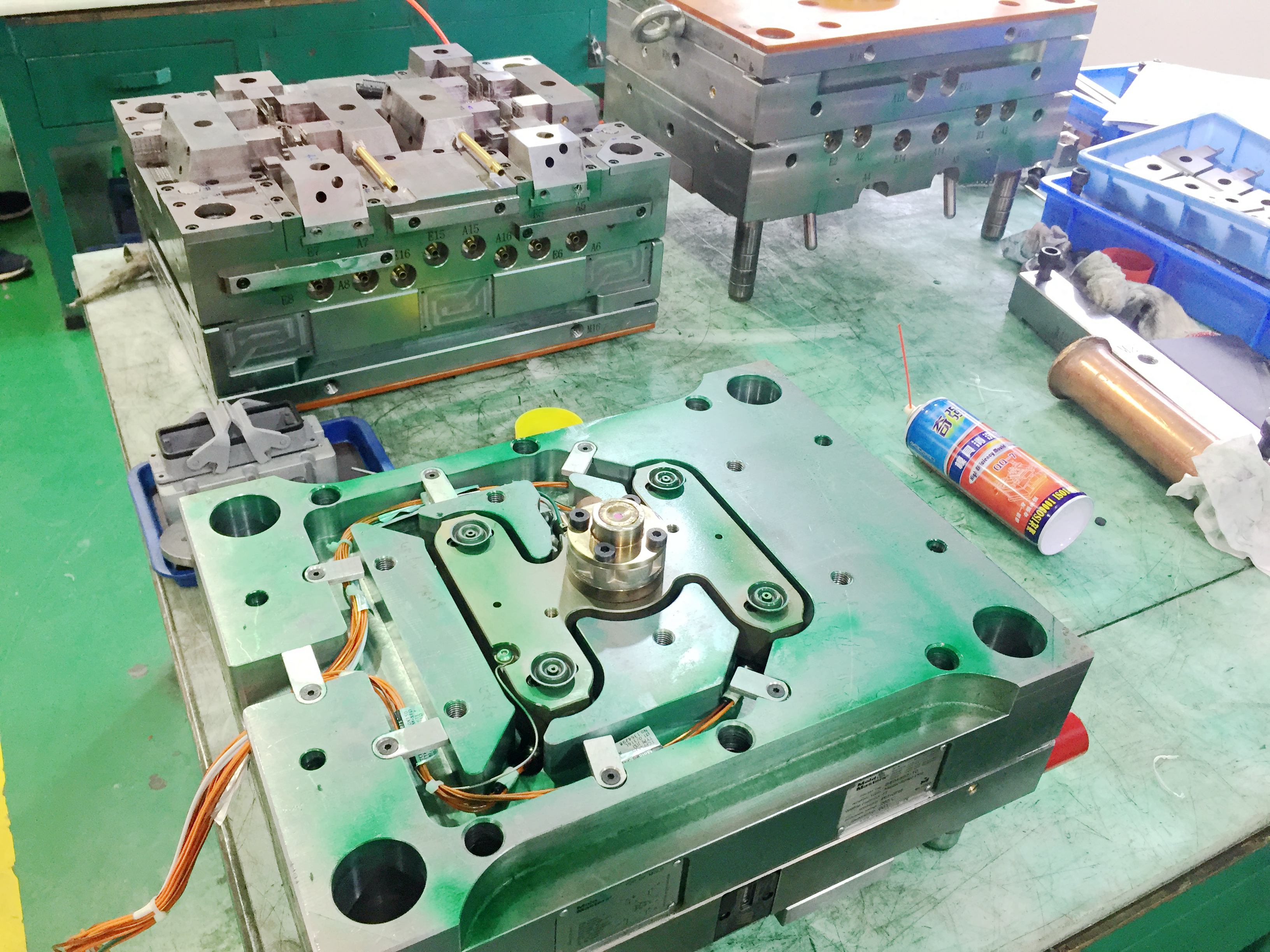

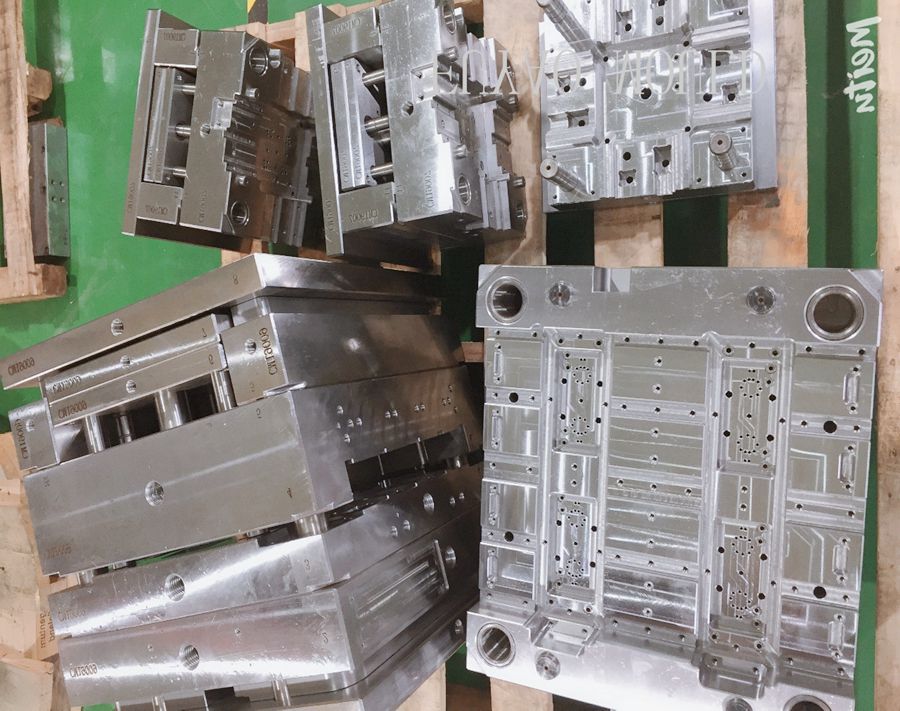

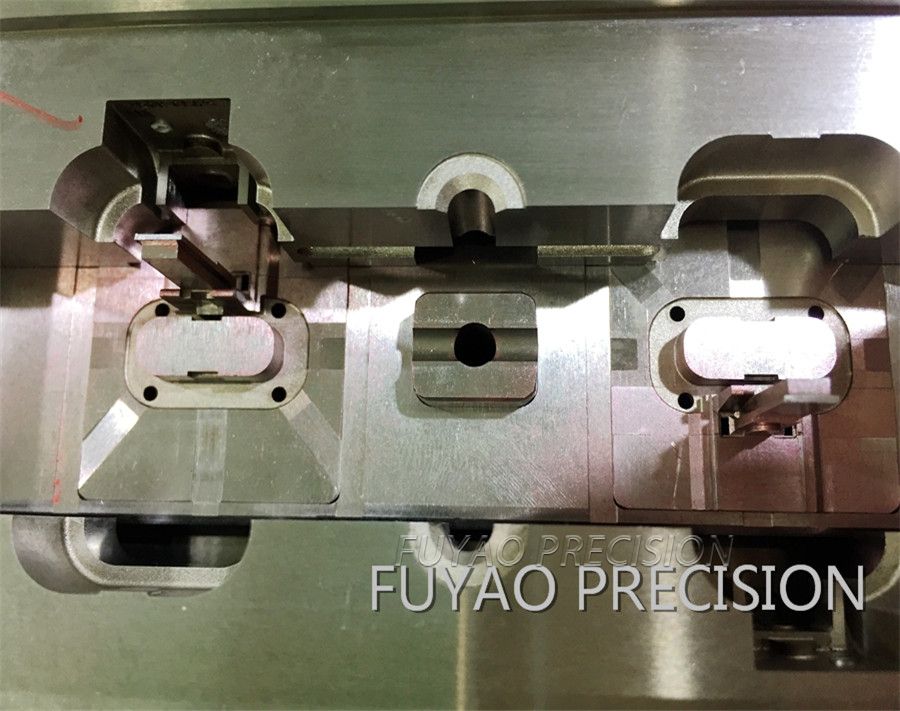

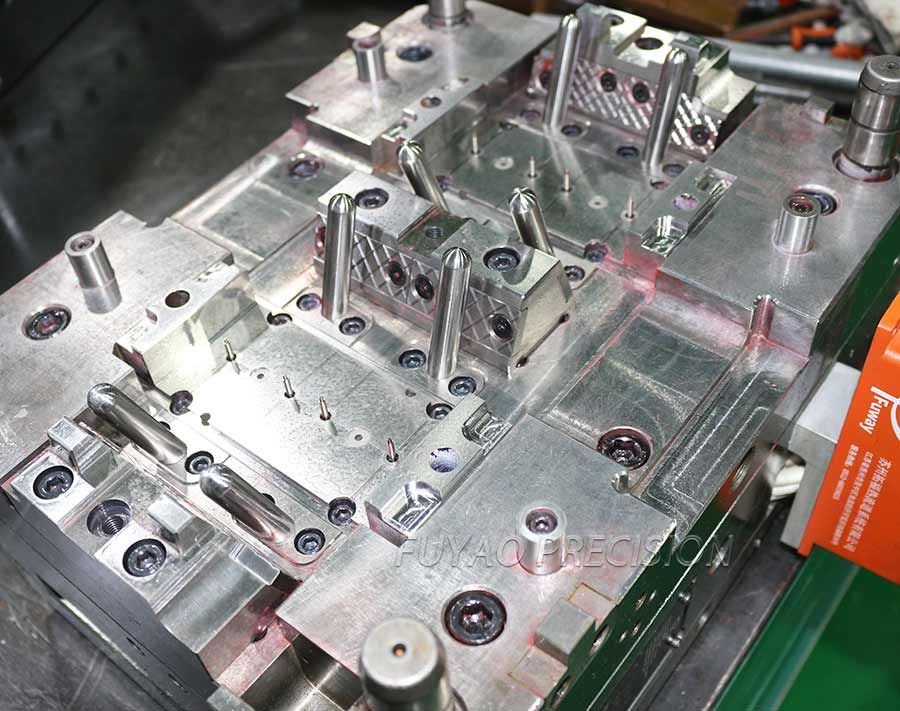

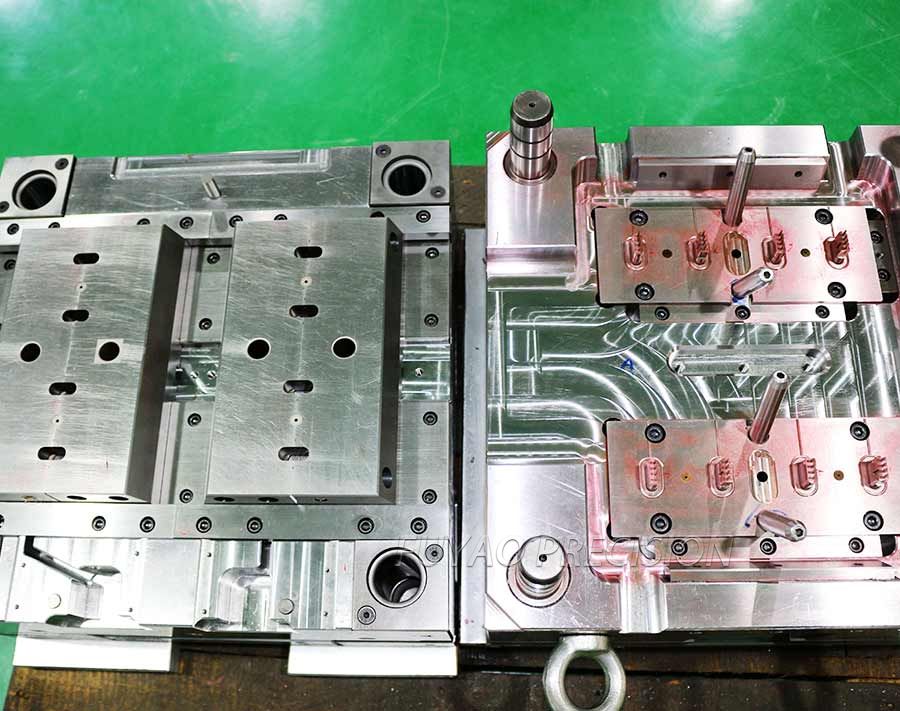

Precision Plastic Injection

Molding Tools Manufacturer

Dongguan Fuyao Precision Mould Co., Ltd. is a high-tech enterprise specializing in the design, development, and manufacturing of precision injection molding tools, hardware molds, and stamping dies since 2005.