About GRM Machinery

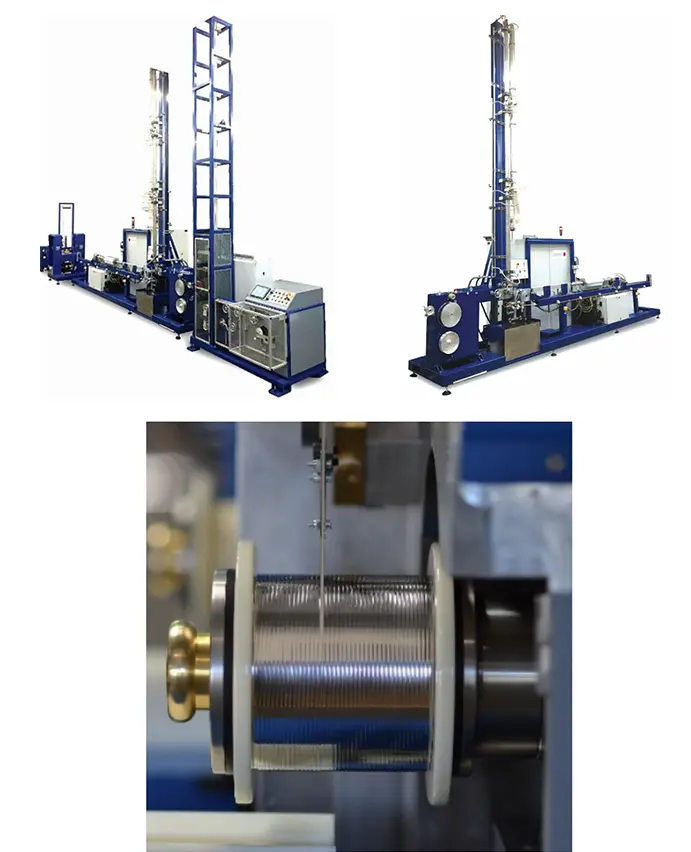

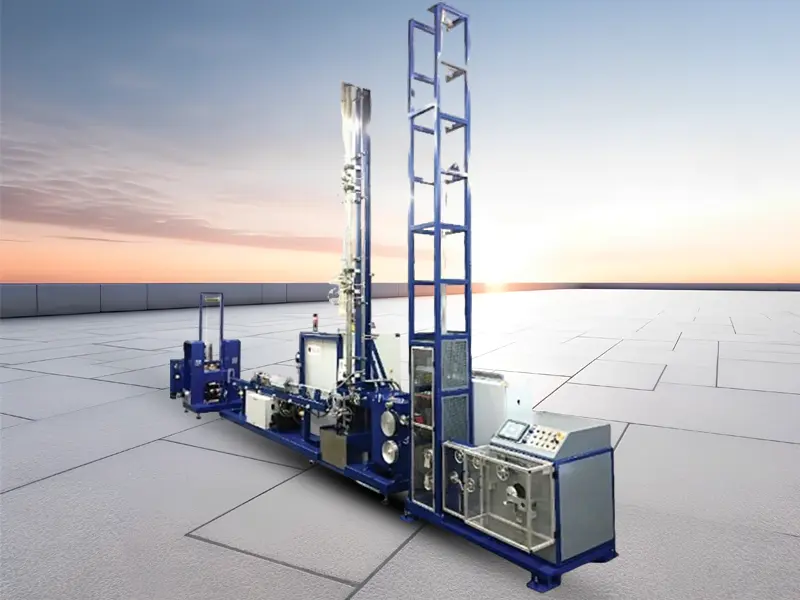

Jiangsu Youzha Machinery Co., Ltd. (GRM) traces its origins to Zhangjiagang Hongxinyuan Technology Co., Ltd., founded in 2008. After strategic restructuring in 2015, GRM has become a leading domestic manufacturer of intelligent precision rolling mills and photovoltaic (PV) ribbon equipment.

16+ Years of Metal Forming Excellence

Since 2004, GRM has been deeply engaged in the field of metal forming, accumulating extensive expertise in precision engineering and advanced manufacturing.

As of 2025, the company employs 60 professionals, with R&D personnel accounting for over 30% of the workforce. We hold 50+ patents, including breakthrough technologies such as the "Polygonal Wire Automatic Feeding Device" and "Busbar Rolling Equipment."

- 50+ Patents in Metal Forming

- 30% R&D Workforce

- ISO-Certified Manufacturing

- Global Presence in 50+ Countries