About GW Valves

Zhejiang Guangwo Valve Co., Ltd. was founded in 2016 and is located in Wenzhou, China. The company covers an area of 40,000 square meters and employs over 70 skilled staff with more than 100 sets of advanced manufacturing and testing facilities.

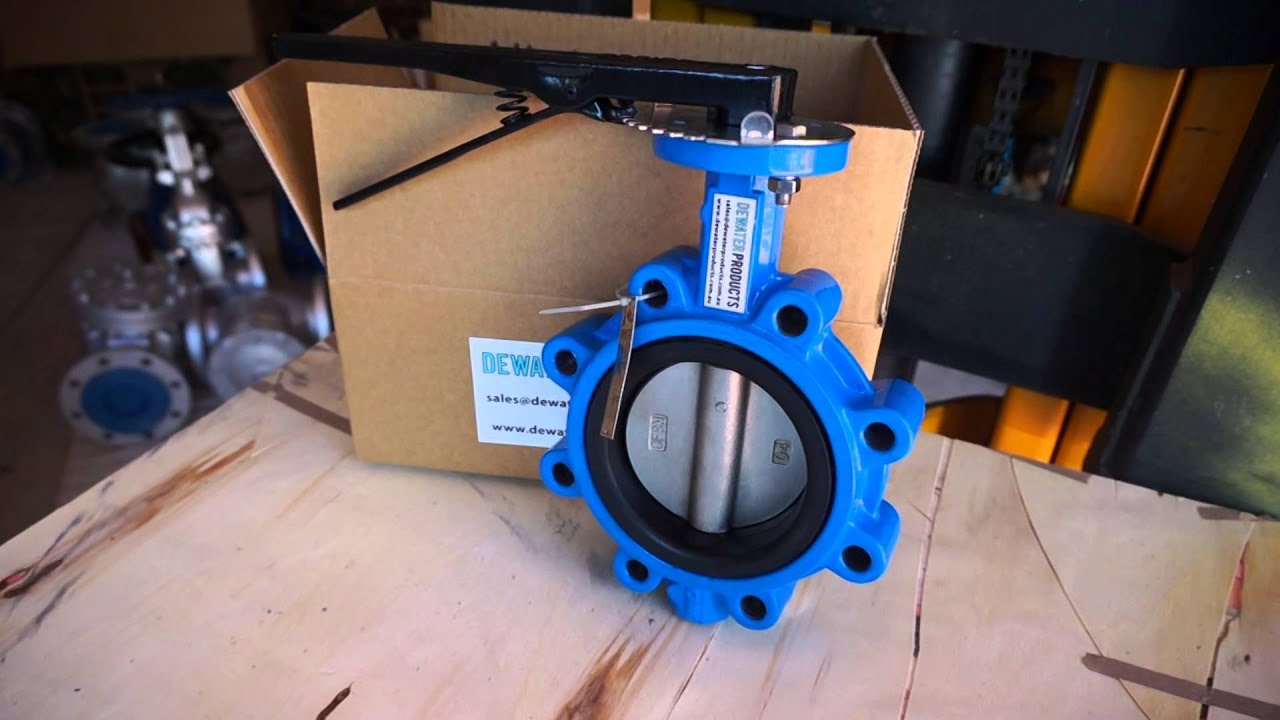

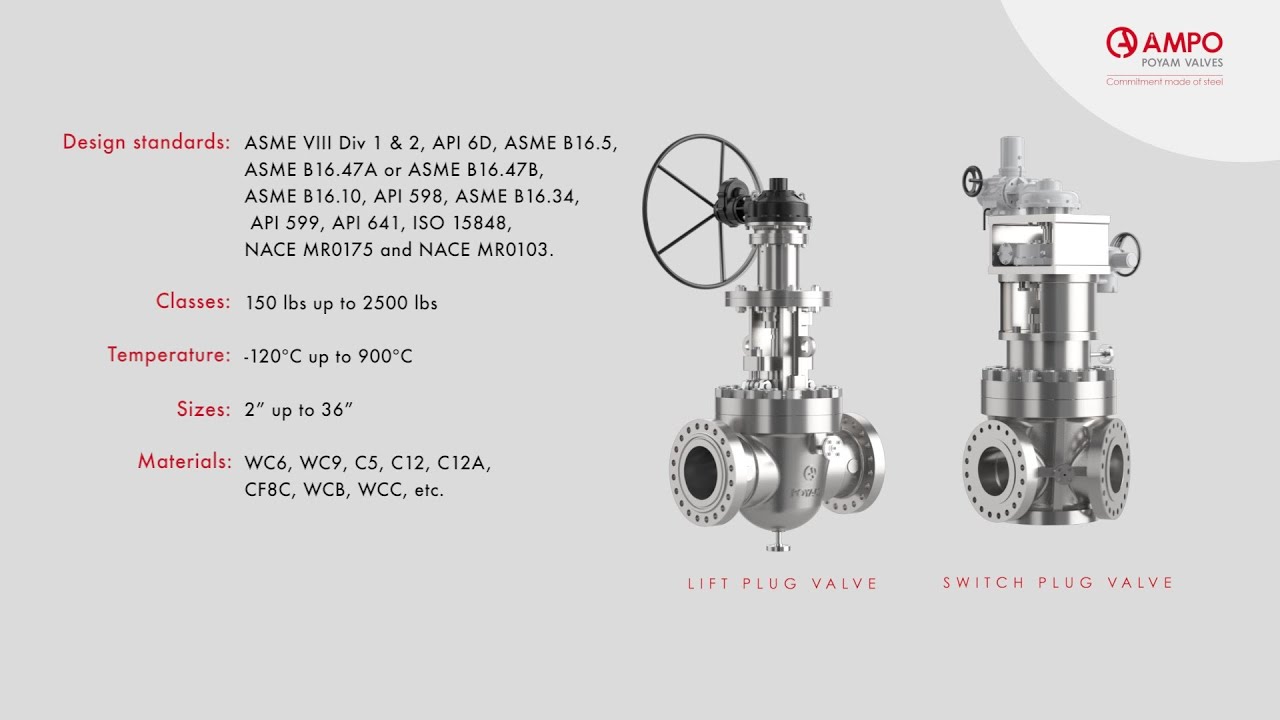

We specialize in the design and production of industrial valves including gate valves, globe valves, check valves, butterfly valves, plug valves, and strainers. Our products are made from carbon steel, alloy steel, and stainless steel, and are manufactured in compliance with international standards such as ANSI, API, DIN, GOST, and GB.