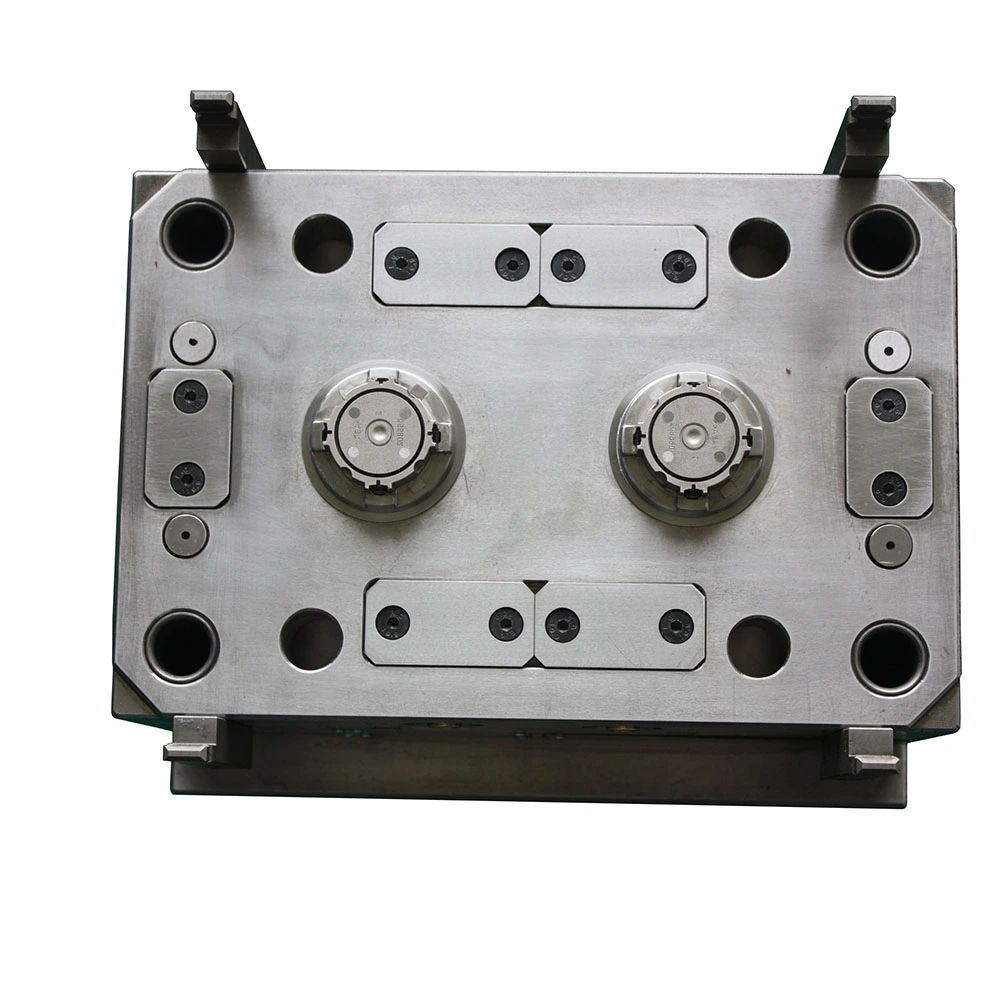

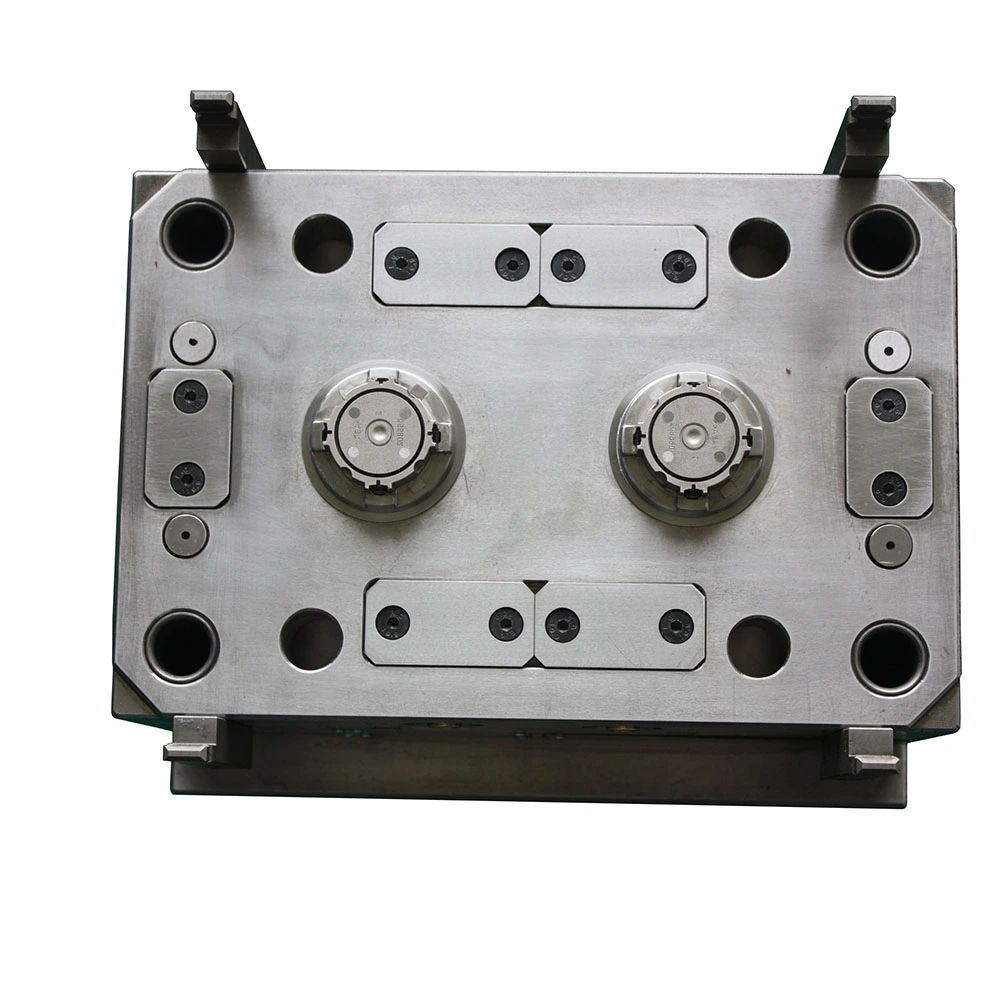

Plastic Injection Mould

Manufacturer in China

One-stop custom plastic mold design & manufacturing since 1996

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

One-stop custom plastic mold design & manufacturing since 1996

HanKing Mould Engineering Ltd. started the China custom plastic mold business in 1996 as a professional plastic mold manufacturer in Longgang, Shenzhen, China. With over 25 years of continuous development, we have become a trusted name in precision plastic injection molding.

We offer one-stop plastic mold manufacturing services including custom injection mold design, project management, mold manufacturing, mold trials, quality control, and assembly. Our mission is to deliver excellence in every mold we produce.

Specialized in high-precision plastic injection molds for automotive, medical, electronics, and industrial applications.

High-precision molds for car parts including sensors, switches, fuse holders, and expansion tanks. Compliant with TS16949 standards.

Precision molds for adapters, chargers, terminal blocks, and travel plugs. Designed for high-volume production and reliability.

Dual-material injection molds for ergonomic grips, seals, and over-molded components. TPE, silicone, and multi-color capabilities.

ISO 13485-compliant molds for diagnostic devices, housings, and surgical tools. Cleanroom production and strict QC protocols.

Tolerance down to ±0.002mm. Ideal for micro gears, connectors, and optical components. High-gloss and texture finishes available.

High-efficiency molds with up to 24+ cavities. Optimized for cost-effective mass production of small to medium parts.

Durable molds for coffee machines, sewing machines, funnels, and household components. ABS, PP, and PC compatible.

Metal or pre-formed parts embedded in plastic. Ideal for terminals, connectors, and structural components requiring strength.

Advanced engineering and manufacturing for precision plastic molds

Using ProE, SolidWorks, UG, and AutoCAD for precise 3D modeling, flow analysis, and structural optimization.

CNC, EDM, wire cutting, grinding, and polishing. Tolerance control to ±0.002mm with mirror and texture finishes.

In-house injection machines for sample trials, dimensional checks, and functionality validation before delivery.

ISO 9001, TS16949, and ISO 14001 certified. Full inspection reports, SPC, and traceability for every project.

Dedicated PMs for seamless communication, timeline tracking, and milestone reporting from concept to delivery.

Ultrasonic welding, laser marking, pad printing, and final assembly services for complete turnkey solutions.

State-of-the-art manufacturing and quality control environment

Equipped with CNC machining centers, EDM, wire-cut, and precision grinding machines for mold core and cavity fabrication.

In-house molding machines for prototype and production runs. Capable of 2K, insert, and micro-injection molding.

Equipped with CMM, projector, hardness tester, and optical comparators for full dimensional and material verification.

Get in touch for a quote or technical consultation

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info