About HeatshrinkChina

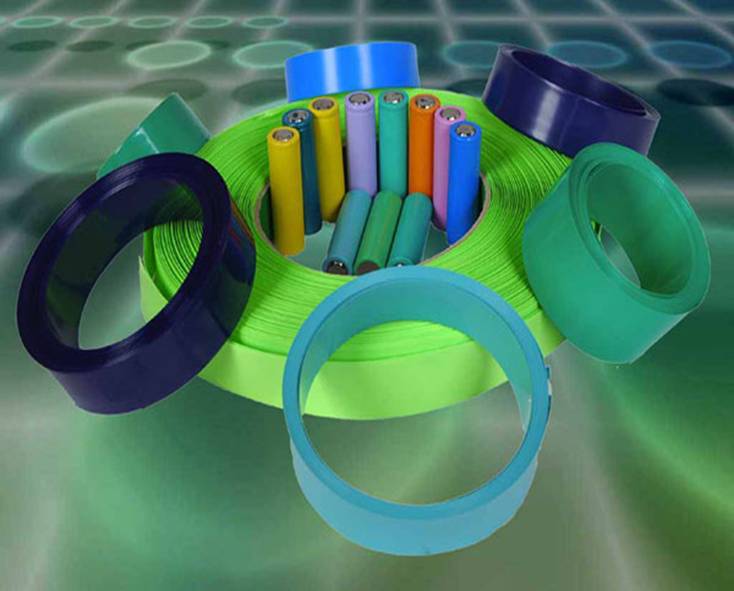

As a pioneering heat shrinkable tubing manufacturer since 1991, HeatshrinkChina has built a global reputation for innovation, durability, and precision engineering. We specialize in advanced polymer-based insulation solutions for industrial, electrical, aerospace, and marine applications.

Our product line includes 2:1, 3:1, and 4:1 shrink ratios across polyolefin, dual/medium/heavy wall, adhesive-lined, and specialty materials like Viton, PVDF, Kynar, PFA, and FEP. We also manufacture busbar insulation sleeves rated from 0.6kV to 36kV, stress control systems, anti-tracking breakouts, and cold shrink terminations.