About HHD Industrial Ltd

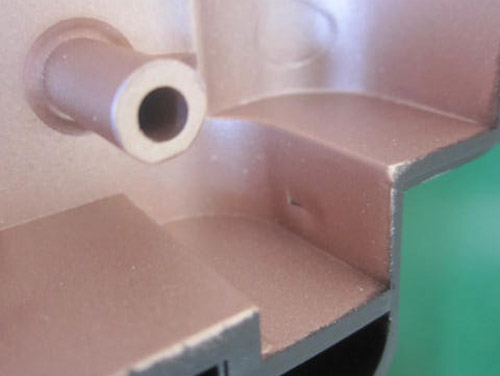

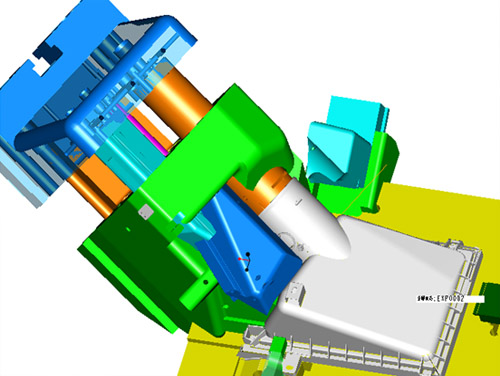

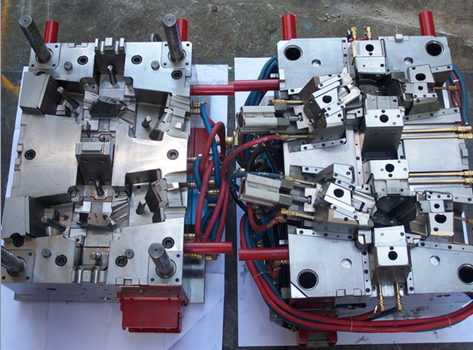

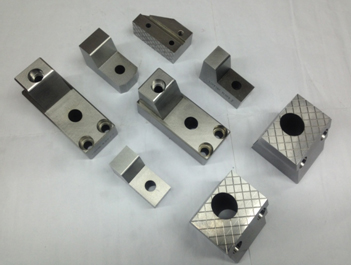

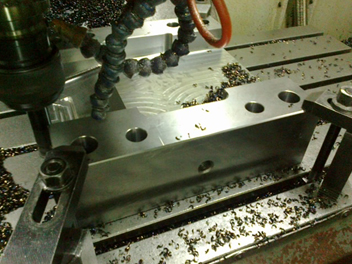

HHD Industrial Ltd is a leading provider of precision manufacturing and engineering solutions based in Dongguan, China. With years of experience in injection molding, CNC machining, and rapid prototyping, we serve clients across diverse industries including automotive, medical, electronics, and consumer goods.

Our team of skilled engineers and technicians is committed to delivering high-quality products with fast turnaround times. We combine advanced technology with strict quality control processes to ensure every component meets international standards.