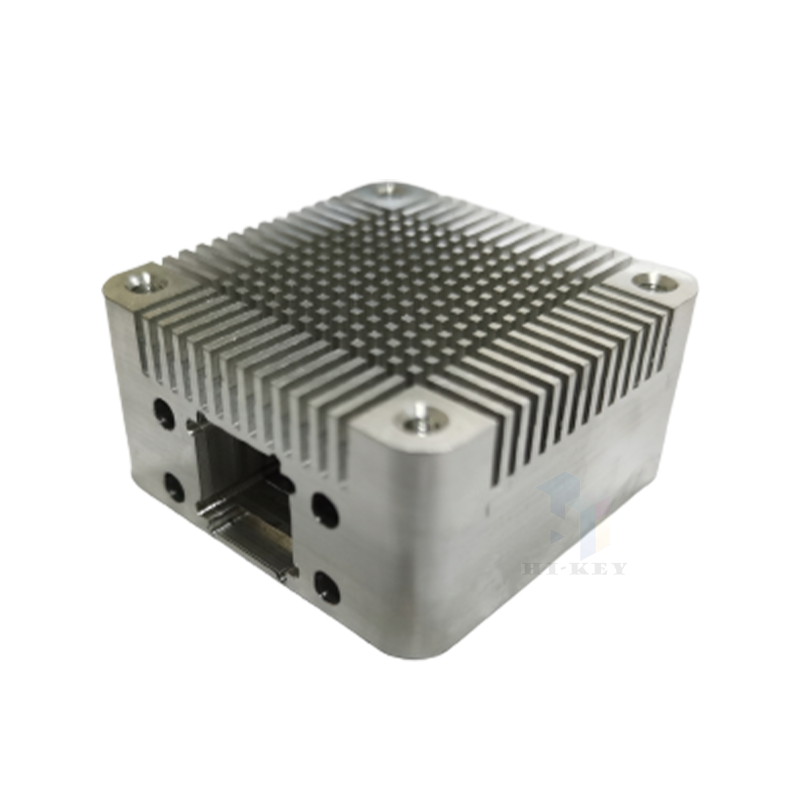

About Hi-Key Precision

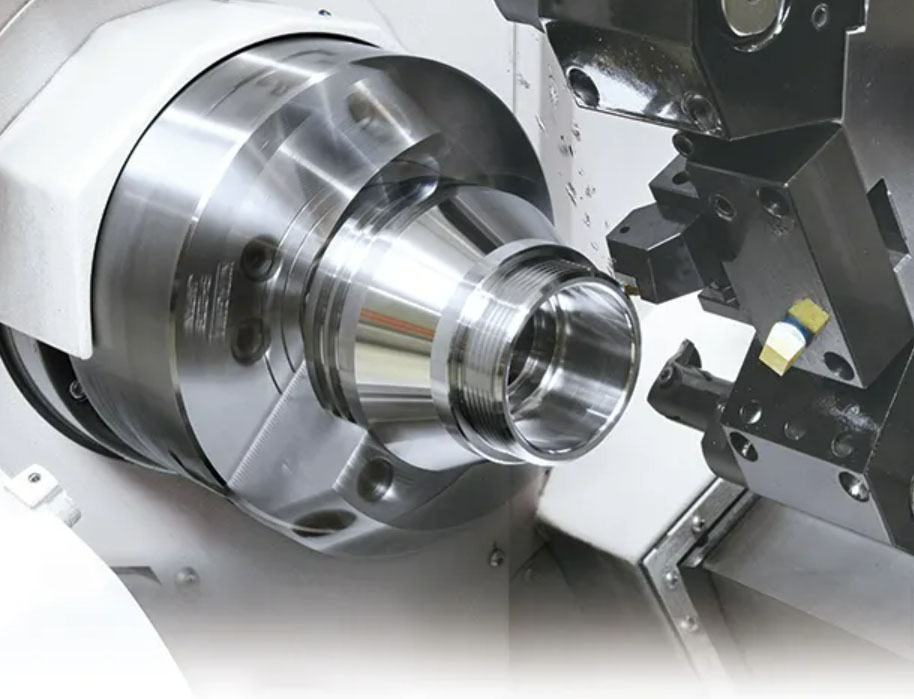

Located in Dongguan, Guangdong, China, Hi-Key Precision Machining Ltd. has been a trusted provider of precision machined components since 2008. We specialize in delivering high-tolerance parts for industries where reliability and performance are non-negotiable.

Our mission is to serve every customer sincerely by adhering to a people-oriented, customer-first principle. We ensure full inspection of critical dimensions, competitive pricing, and fast delivery times—making us a reliable partner in precision manufacturing.

2008

Founded

15+ Years

Industry Experience