Welcome to HUAKAIYU Technology

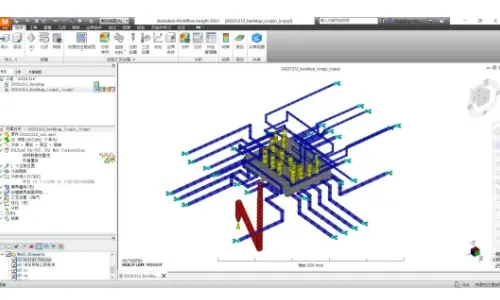

HUAKAIYU is a Chinese precision mold manufacturer specializing in high-quality metal and plastic component production, custom injection molds, advanced plastic molding, MIM (Metal Injection Molding) metal powder injection molds, die casting molds, and precision mechanical parts machining.

Our customers range from small startups to large multinational corporations, demonstrating our extensive capabilities, comprehensive services, and unwavering commitment to excellence in every project.