Precision Metal Forming Machinery

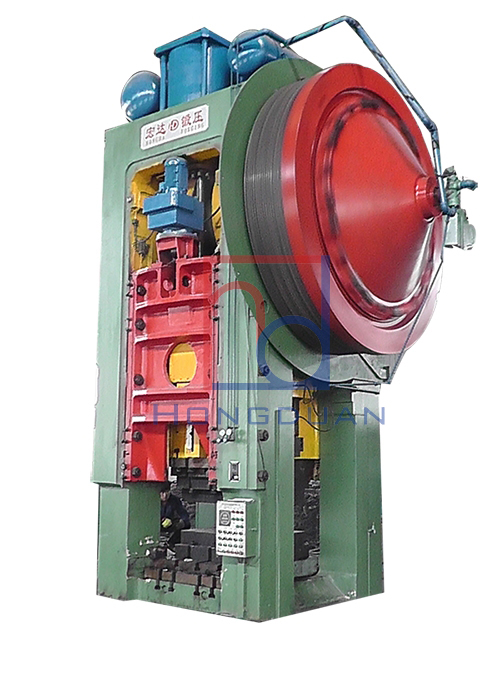

Qingdao Hongda Metal Forming Machinery Co., Ltd. delivers high-performance electric screw presses, hot forging presses, friction screw presses, and brick presses for industrial manufacturing worldwide.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Qingdao Hongda Metal Forming Machinery Co., Ltd. delivers high-performance electric screw presses, hot forging presses, friction screw presses, and brick presses for industrial manufacturing worldwide.

With years of expertise in metal forming technology, Qingdao Hongda Metal Forming Machinery Co., Ltd. is a leading manufacturer of industrial pressing equipment. We specialize in designing and producing high-efficiency, durable machines for hot forging, cold forming, and brick manufacturing.

Our commitment to innovation, quality control, and customer satisfaction has made us a trusted partner for manufacturers across Asia, Europe, and North America.

Years Experience

Countries Served

Discover our range of high-performance presses engineered for precision, durability, and efficiency in metal forming and construction material production.

High-efficiency electric drive system with precise energy control for hot and cold forging applications.

Robust friction drive system ideal for both hot and cold forging in heavy-duty environments.

Designed for high-temperature forging operations with excellent thermal stability and control.

Advanced dual-disc transmission for smoother operation and enhanced energy transfer.

Heavy-duty press for manufacturing solid concrete and clay bricks with high compaction force.

We offer custom automation packages including robotic loaders, conveyors, and PLC integration.

Genuine components for all Hongda press models to ensure longevity and performance.

On-site and remote training programs for operators and maintenance teams.

Engineered for performance, reliability, and long-term value.

Each machine undergoes rigorous testing and quality checks before shipment.

Electric and hybrid models reduce power consumption and operational costs.

After-sales service and technical support available in over 50 countries.

Tailored solutions to meet specific production requirements and workflows.

Performance you can count on.

Machines Installed

Countries

Support Availability

Customer Retention

Our electric and friction screw presses are ideal for both hot and cold forging of metals such as steel, aluminum, and copper alloys in automotive, aerospace, and hardware industries.

Yes, we provide on-site installation, machine calibration, and operator training to ensure smooth startup and optimal performance.

We maintain a comprehensive inventory of original spare parts and can ship globally within 7–10 business days.

Absolutely. Our presses are designed with standard interfaces for integration with robotic arms, conveyors, and SCADA systems.

Standard models are delivered within 60–90 days after order confirmation. Custom configurations may require additional time.

For product inquiries, technical support, or custom solutions, visit our official website to contact the Hongda team.

All product specifications and company information are subject to change without notice. Please refer to the official site for the latest updates.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info