About Beijing Huateng Zhengcheng

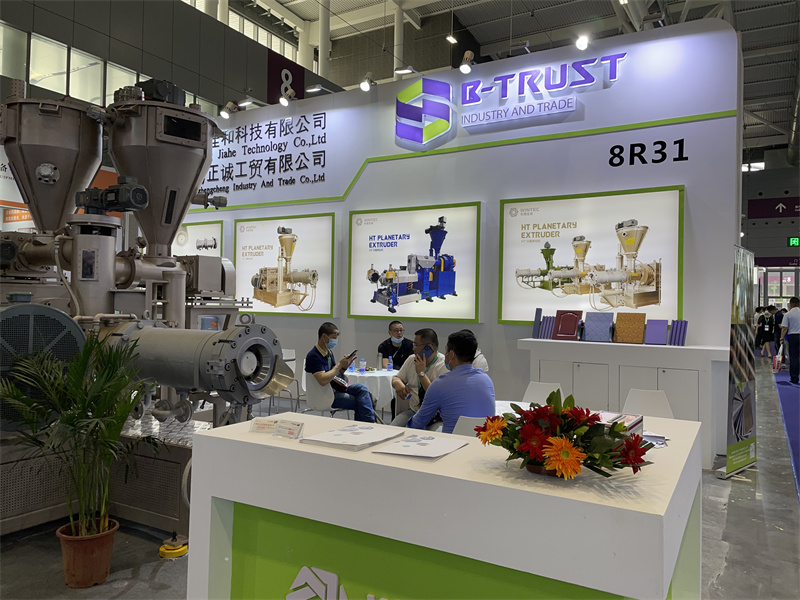

Beijing Huateng Zhengcheng Industry and Trade Co., Ltd. is a professional manufacturer specializing in the research, development, and production of advanced plastic processing equipment.

With years of engineering expertise, we provide reliable solutions including planetary extruders, continuous mixers, and plastic pelletizing machines designed for high output, energy efficiency, and long-term durability.

Our mission is to deliver innovative, high-value machinery that supports sustainable industrial growth across global markets.