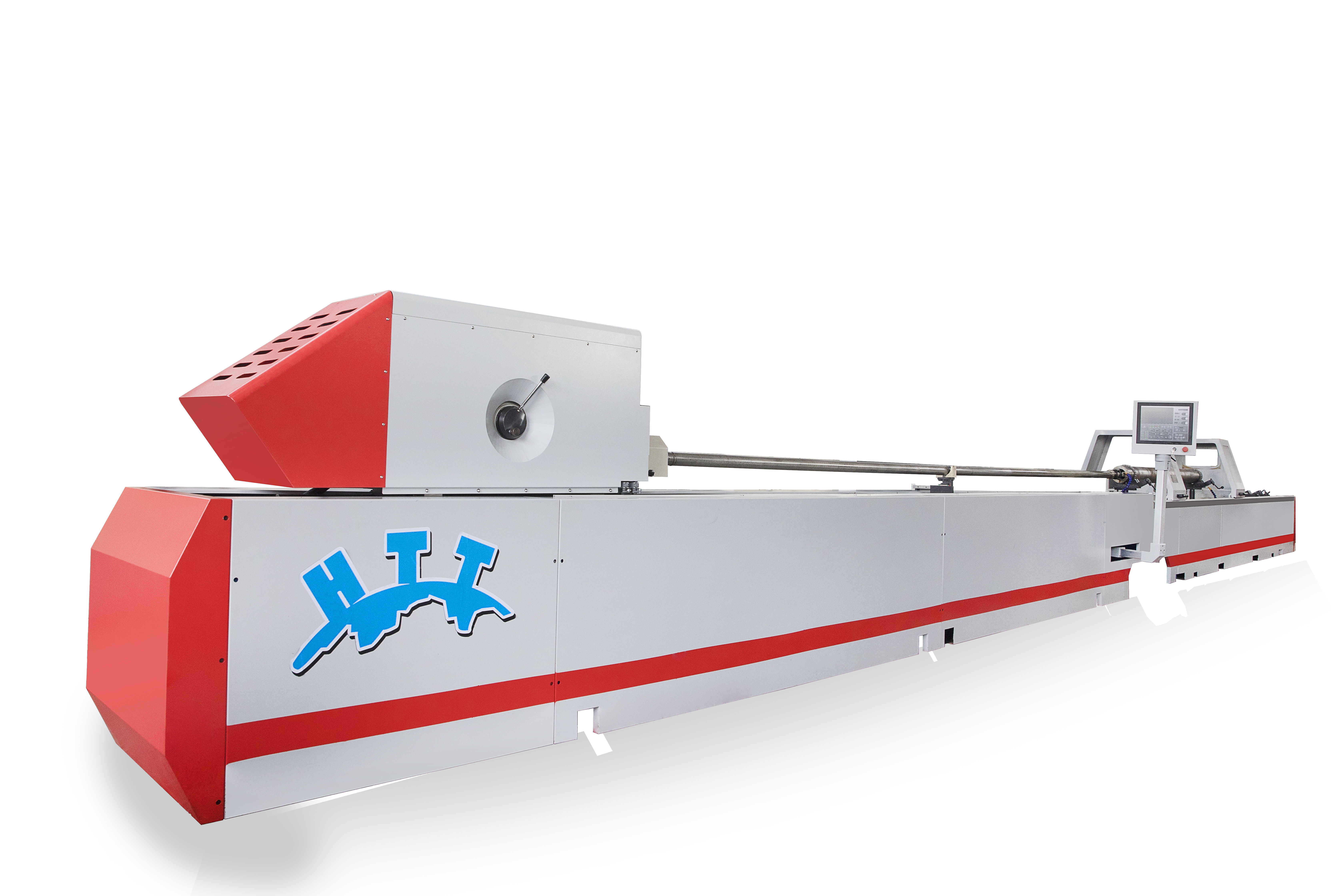

About HTT USA Inc.

HTT USA Inc. is a leading provider of deep hole drilling technology, specializing in high-precision machining solutions for industries where conventional methods fall short. With over 10 years of experience, we deliver reliable, cost-effective, and innovative drilling systems.

Our facility is conveniently located in Grayslake, Illinois — just a 40-minute drive from O’Hare International Airport — and easily accessible via Highway 94. We serve clients across North America with fast turnaround times and exceptional service.