Who We Are

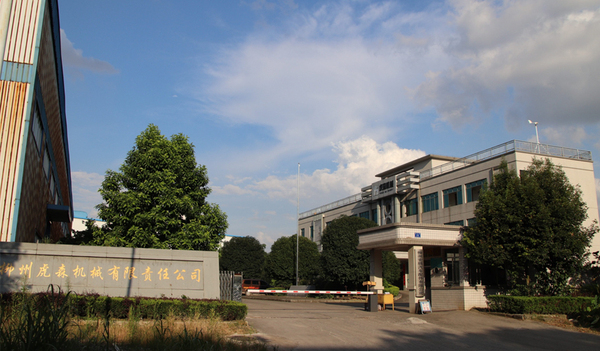

Husen Machinery is a complete engineering and manufacturing company based in Liuzhou City, Guangxi, China. Since our certification under ISO9001:2000 in 2004, we have been committed to delivering high-quality steel fabrications and machining services to global clients.

With over 300 skilled workers and a factory spanning 42,000 square meters, we offer end-to-end production capabilities — from raw material processing to final assembly and painting.

42,000 m²

Factory Area

300+

Skilled Workers

2004

ISO Certified Since

18+ Years

Industry Experience